Automatic mask paging and sheet feeding machine

A mask and paging technology, applied to clothing, tools for sewing clothes, clothing, etc., can solve the problems of slow running speed, prone to two or no suction, poor efficacy, etc. Fast and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

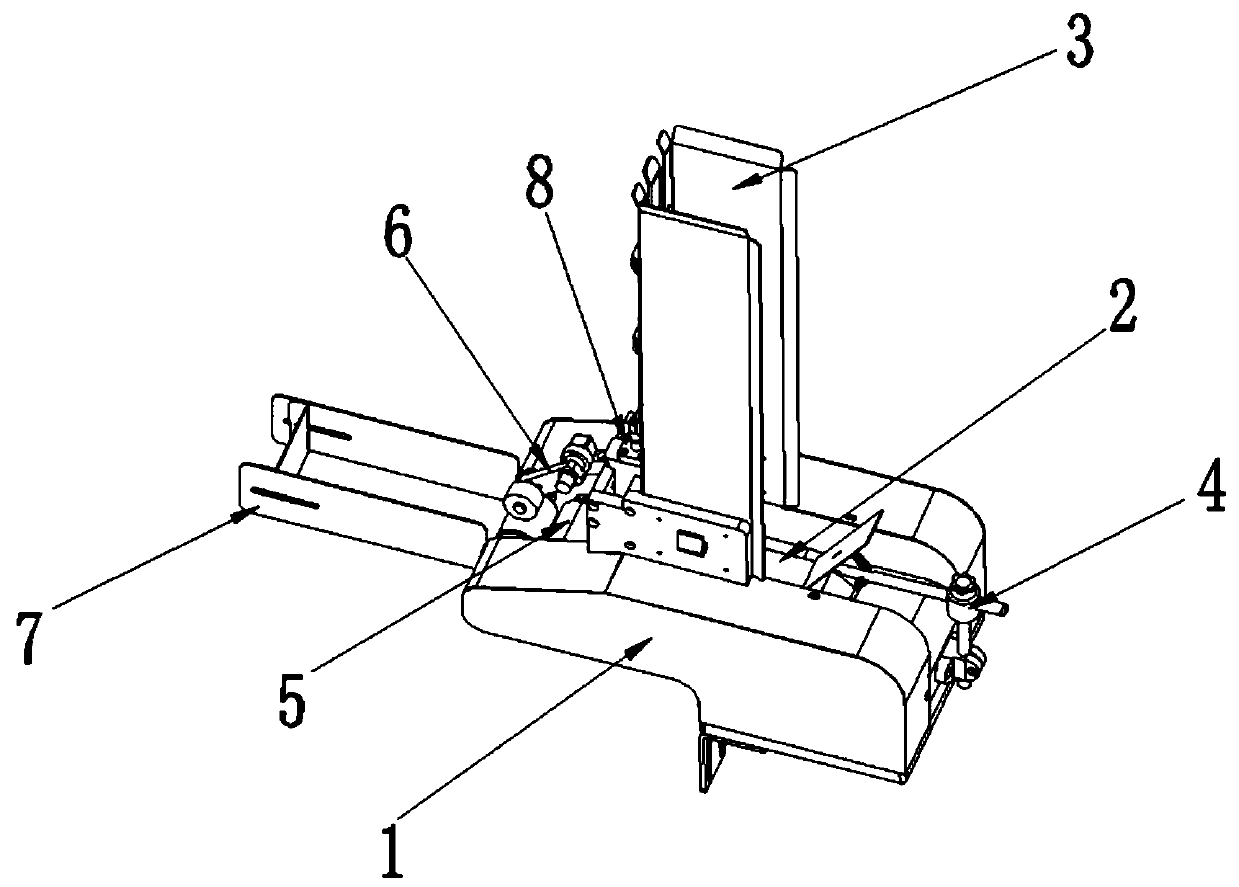

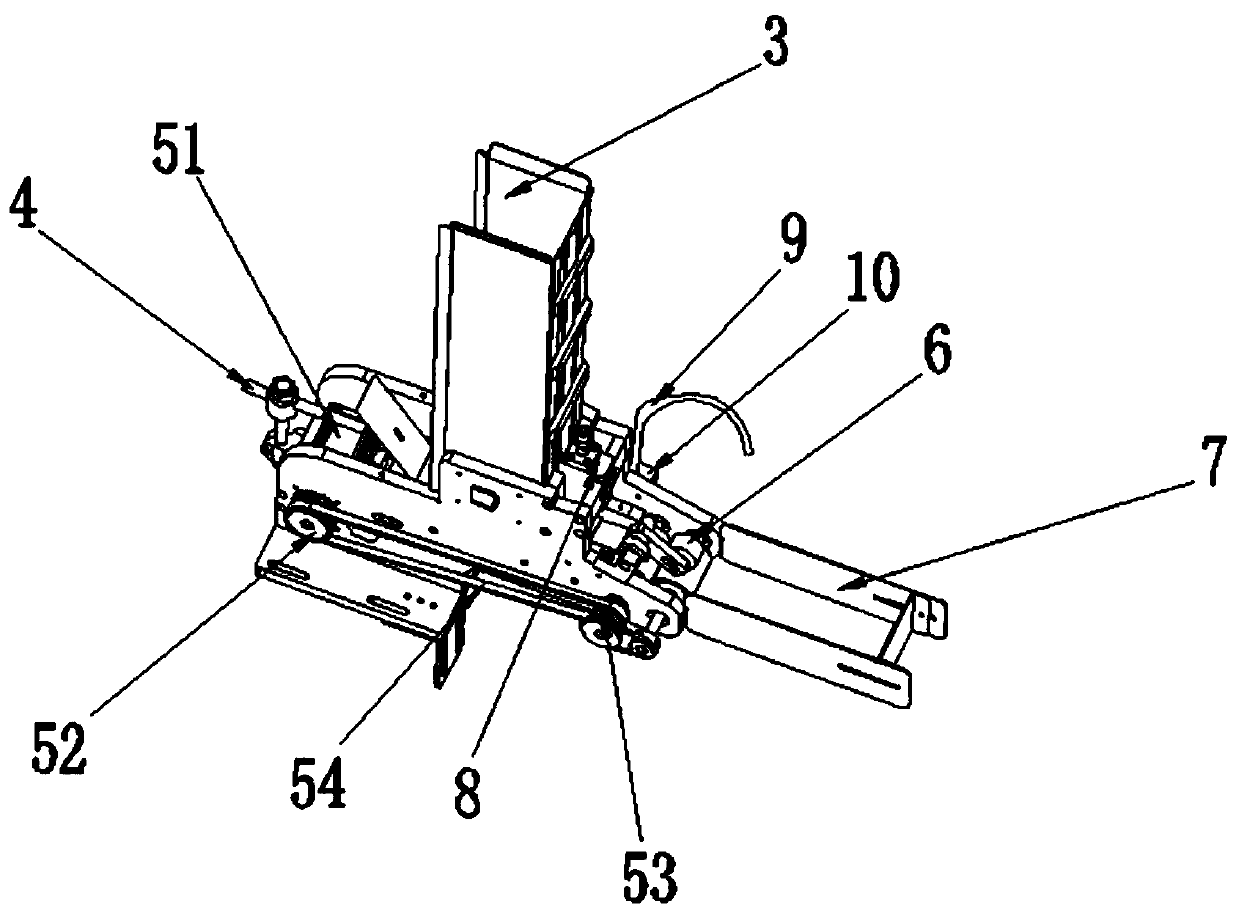

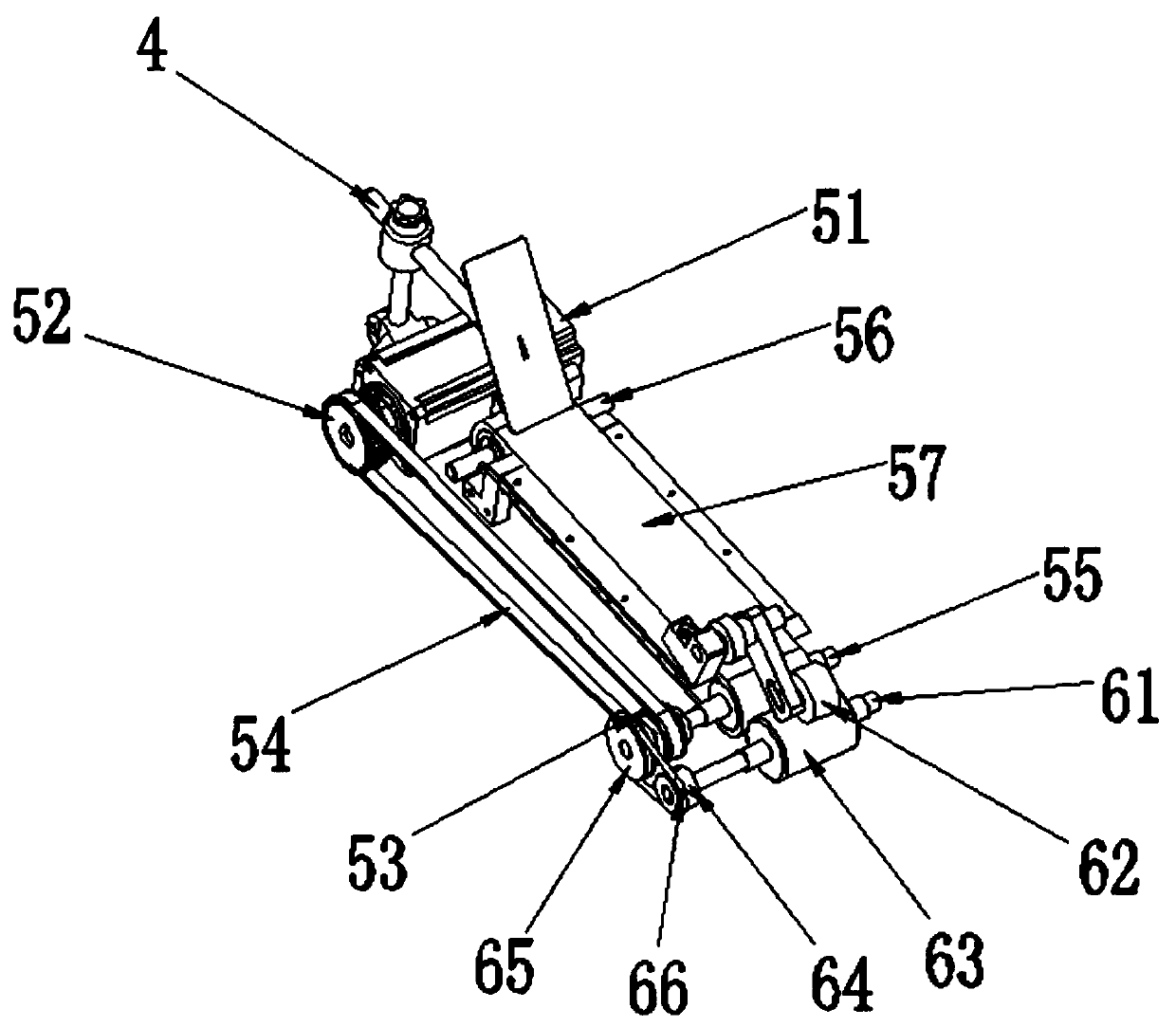

[0035] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0036] Please refer to Figure 1-7 , a kind of automatic mask sheet feeding machine, frame 1, is provided with in the frame 1 and is used for conveying the conveying channel 2 of mask sheet forward; , the conveying channel 2 is provided with a discharge chute 3 connected thereto, and the discharge chute 3 is used to place the mask sheets to be divided into pieces; behind the discharge chute 3, there is a mask for supporting and putting into the discharge chute 3 The material supporting mechanism 4 of sheet; Be provided with the pagination device 8 that is used to carry out sheeting to mask sheet in discharge chute 3 front;

[0037] In one embodiment, an indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com