Long-term stable curing method for thermal copolymerization of arsenic sulfide slag

A technology of arsenic sulfide and copolymerization, which is applied in the direction of protective devices against harmful chemicals, etc., and can solve problems such as increased arsenic leaching concentration, poor anti-aging performance of cured body, and decreased curing and stabilization effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

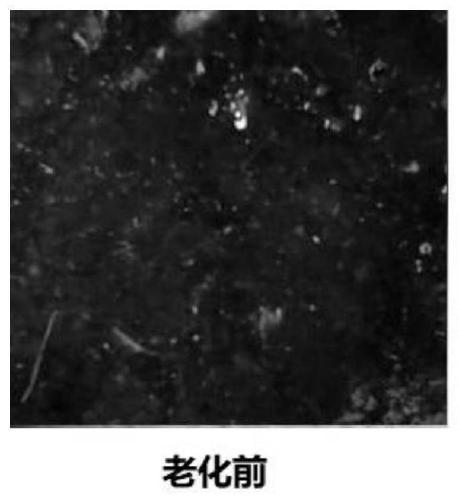

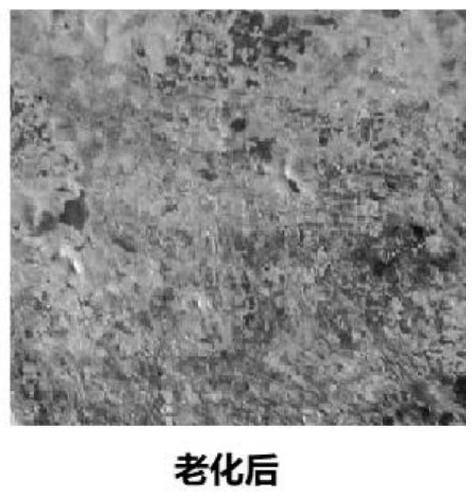

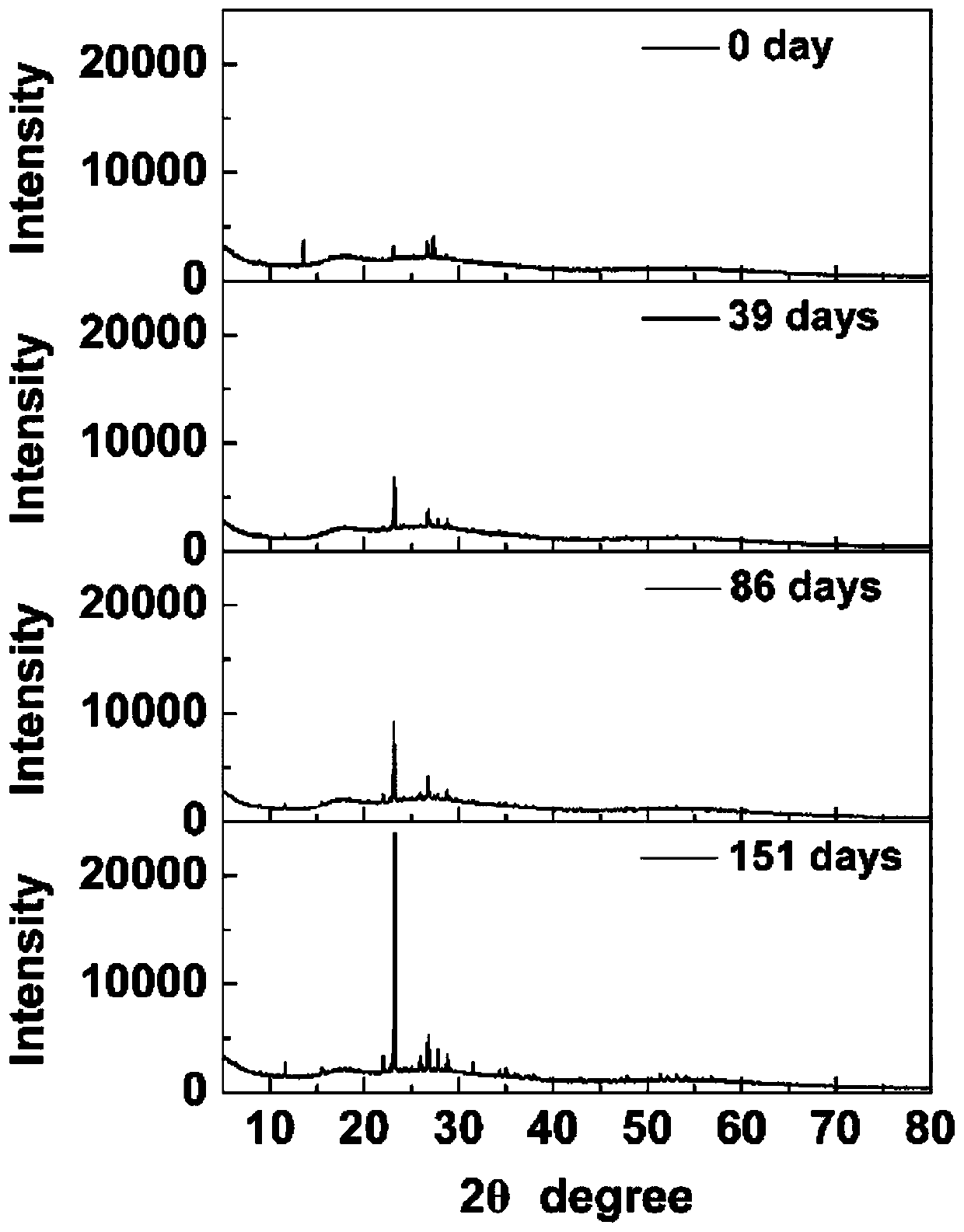

[0032] The arsenic sulfide slag obtained by sulfide removal of arsenic from polluted acid wastewater, industrial-grade sulfur powder, and cyclopentadiene are stirred and heated at 140°C until melting at a mass ratio of 1:2:0.3, and then cooled to obtain a solidified arsenic sulfide slag. The specific flow chart can be found in Figure 4 . The leaching concentration of arsenic in the obtained solidified body is 0.5mg / L (sulfuric acid nitric acid method, HJ / T299-2007), and after 18 months at room temperature, the leaching concentration of arsenic is 0.49mg / L, the volume expansion ratio is 0.48, and the compressive strength 10.5MPa, which has reached the landfill waste entry requirements specified in the Hazardous Waste Landfill Pollution Control Standard (GB18598-2019) (the arsenic concentration is less than 1.2mg / L). Figure 5 is the topography of the cured body after aging for 18 months, Figure 6 is the volume change of arsenic sulfide slag before and after solidification. ...

Embodiment 2

[0035] The arsenic sulfide slag, waste sulfur powder, and limonene obtained by sulfide removal of arsenic from acidic mine wastewater are stirred and heated at 170°C at a mass ratio of 1:4:0.2 until molten, and then cooled to obtain a solidified arsenic sulfide slag. The leaching concentration of arsenic in the obtained solidified body is 0.35mg / L (sulfuric acid nitric acid method, HJ / T299-2007), and after 12 months at room temperature, the leaching concentration of arsenic is 0.37mg / L, the volume increasing ratio is 0.95, and the compressive strength 11.3MPa, which has reached the entry requirements for landfill waste stipulated in the Hazardous Waste Landfill Pollution Control Standard (GB 18598-2019).

[0036] In the control experiment without adding limonene, the leaching concentration of arsenic in the cured body increased from 1.65mg / L at the beginning to 78.82mg / L after aging for 12 months, which did not meet the pollution control standard for hazardous waste landfill (G...

Embodiment 3

[0038]The sulfurized arsenic slag, waste sulfur mud and sulfur rubber LP-31 obtained by sulfiding the polluted acid wastewater for arsenic removal are stirred and heated at 200°C until melting at a mass ratio of 1:2.5:0.4, and then cooled to obtain a solidified body of arsenic sulfide slag. The leaching concentration of arsenic in the obtained solidified body is 0.89mg / L (sulfuric acid nitric acid method, HJ / T299-2007), and after 9 months at room temperature, the leaching concentration of arsenic is 0.91mg / L, the volume increasing ratio is 0.71, and the compressive strength 11.8MPa, which has reached the entry requirements for landfill waste stipulated in the Hazardous Waste Landfill Pollution Control Standard (GB 18598-2019).

[0039] In the control experiment without adding sulfur rubber LP-31, the leaching concentration of arsenic in the cured body increased from 2.38mg / L at the beginning to 76.36mg / L after aging for 9 months, which did not reach the hazardous waste landfill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com