Pipeline operation robot capable of being recovered in multi-elbow condition for food industry

A technology for operating robots and pipeline robots, which is applied in the field of safe recycling of operating robots, can solve problems such as increased workload, increased wear, and failure of electric control or magnetic control, etc., and achieves the effects of prolonging service life, stable use, and not easy to stop midway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

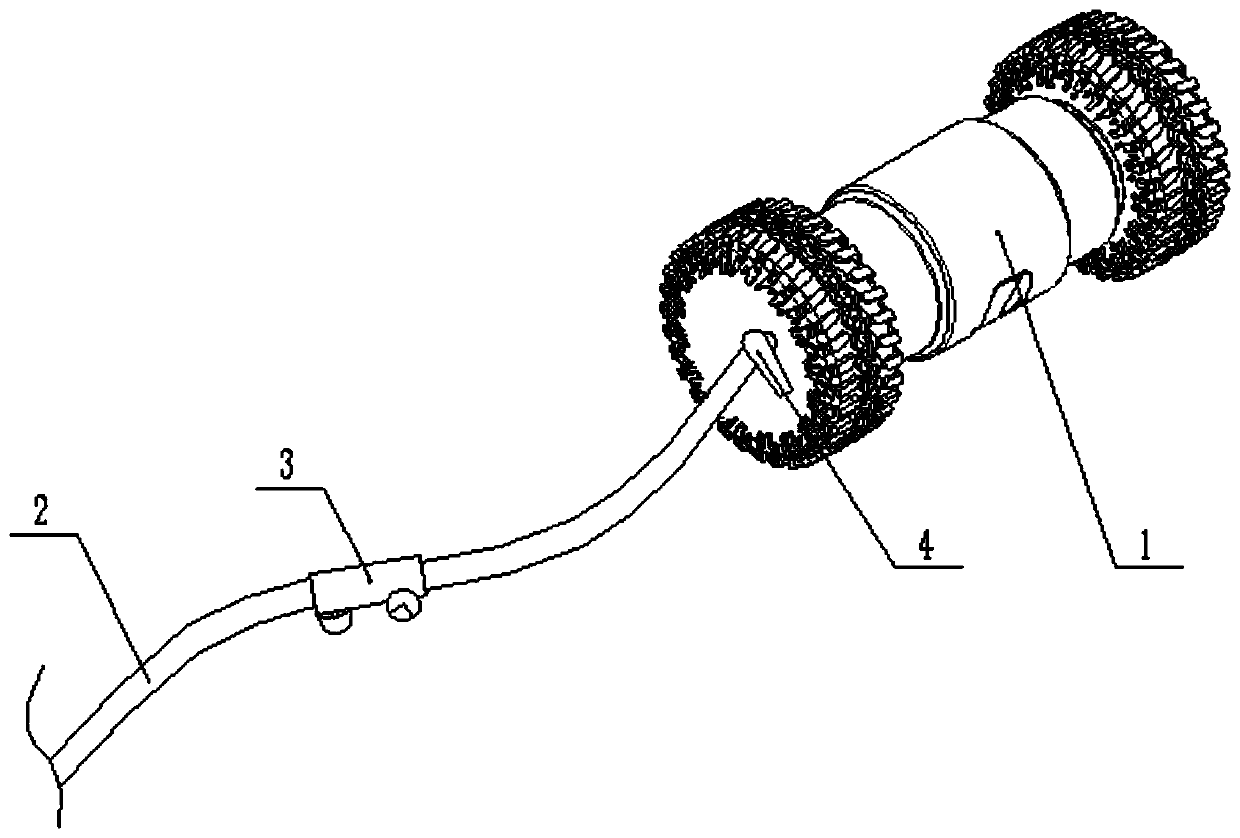

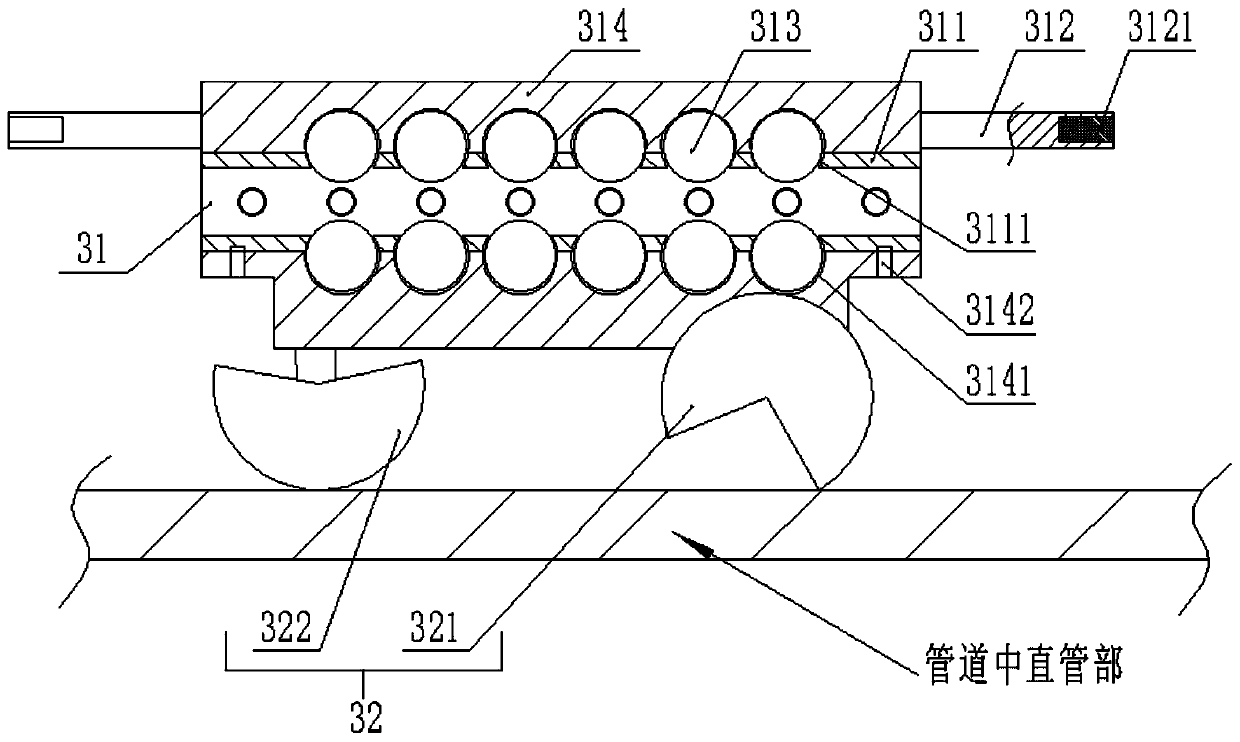

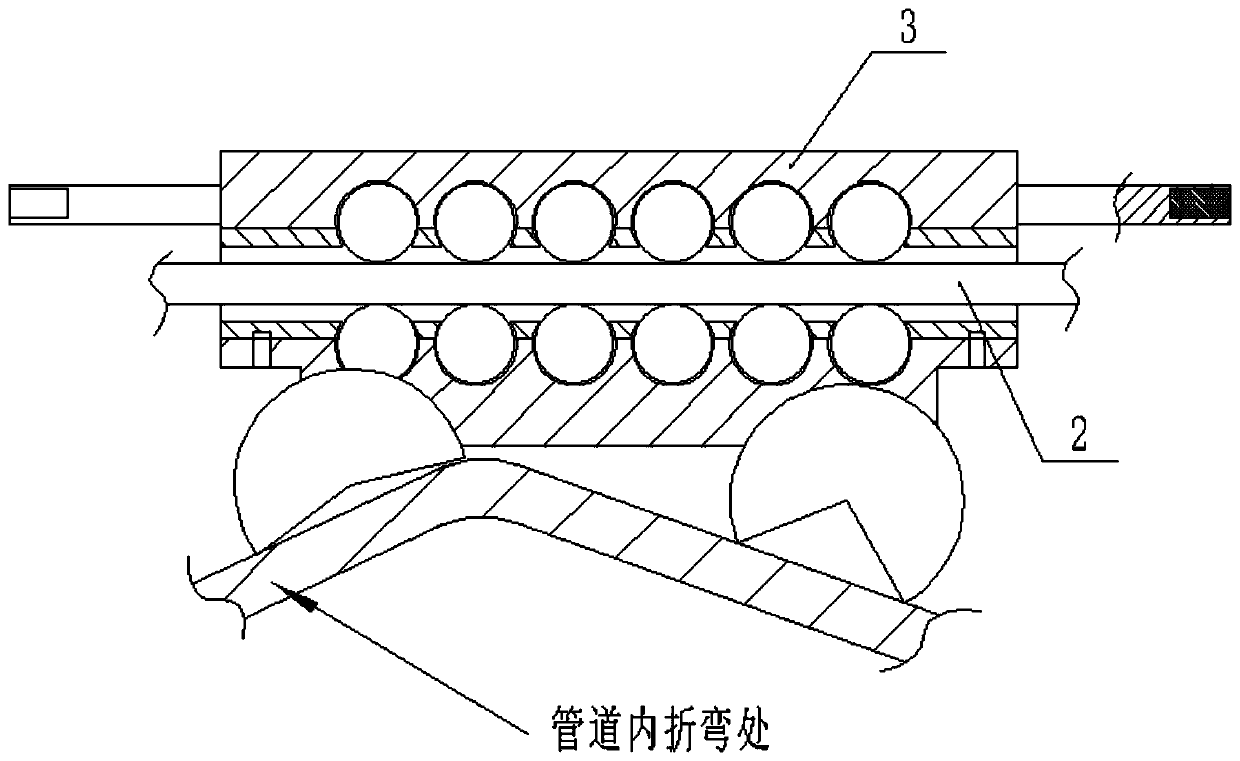

[0027] For details, please refer to figure 1 , figure 2 and image 3 , a recyclable pipework robot for multi-bent pipes in the food industry. Internal operation; the transmission wire 2 is electrically connected to the pipeline robot main body 1; the pipe bending auxiliary device 3 includes a main body part 31 and a notch wheel 32, the notch wheel 32 is installed in the main part 31, and the pipe bending auxiliary device 3 slides on the high-strength body transmission wire Install multiple.

[0028] Specifically in this embodiment, the notched wheel 32 includes a front wheel 321 and a rear wheel 322, and the front wheel 321 and the rear wheel 322 are all provided with fan-shaped notches whose central angle is an obtuse angle, and the fan-shaped notches of the two front wheels 321 are in the axial direction. Staggered from each other, the fan-shaped gaps of the two rear wheels 322 are staggered from each other in the axial direction. In actual use, when encountering a stra...

Embodiment 2

[0030] For details, please refer to figure 1 and Figure 4; This kind of recyclable multi-elbow pipework robot used in the food industry also specifically includes a paddle 4, and the paddle 4 is radially movable and installed at the connection between the transmission wire 2 and the main body of the pipeline robot. This structure enables the paddle 4 to rotate radially arbitrarily, which is convenient for the subsequent use and can be quickly put in place. Specifically in this embodiment, the plectrum 4 includes a plectrum main body 41 and a magnetic coil 42, the plectrum main body 41 is provided with a mounting position 411, the magnetic coil 42 is fixedly embedded in the mounting position 411, and the magnetic coil 42 is provided with a hollow position. 421 , the hollow position 421 is in clearance fit contact with the abutting shaft 312 . In actual use, the magnetic coil 42 can quickly approach the abutment shaft 312, and quickly push aside the bending auxiliary device 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com