A circular pipe inner wall circular seam welding robot

A technology of circular seam welding and robotics, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that the safety and stability of steel pipes cannot be guaranteed, the welding angle is not easy to adjust, and the welding effect is affected. Achieve the effect of providing work efficiency, fast welding work, and reducing trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

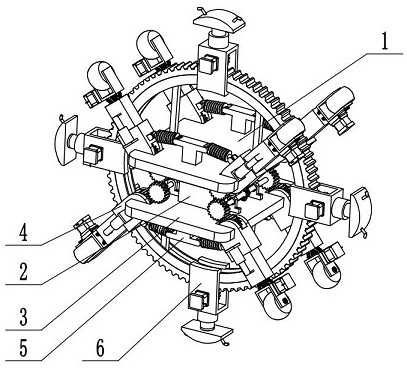

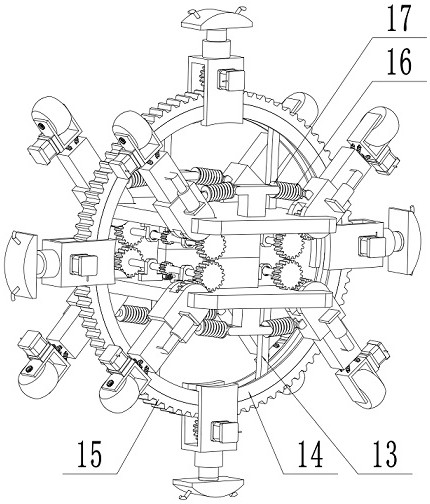

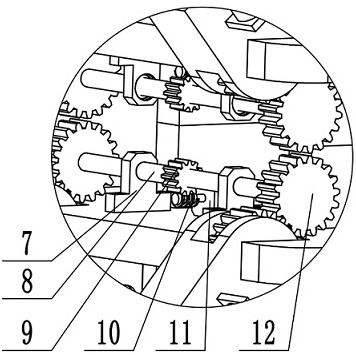

[0024] Example: such as figure 1 , figure 2 , Figure 4 , is a schematic diagram of the overall structure of the present invention, as mentioned above, a circular pipeline inner wall circular seam welding robot, the upper mounting plate 1 and the lower mounting plate 3 selected at first are rectangular steel plates, the lower end surface of the upper mounting plate 1 and the upper end surface of the lower mounting plate 3 are fixedly connected together through the connecting frame 2, and the planes are kept parallel. The structures assembled on the upper mounting plate 1 and the lower mounting plate 3 are symmetrical structures, that is, the mechanisms arranged on both sides are the same, but It is divided into upper and lower structures; the optical axis base 7 is installed on the upper mounting plate 1 by bolts, and the two optical axis bases 7 are installed symmetrically on the center line of the mounting plate 1, and then the optical axis 8 is rotated and installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com