An automatic assembly equipment for air-conditioning accessories and its process

A technology of automatic assembly and accessories, which is applied in the field of air-conditioning materials, can solve problems such as wasting time, and achieve the effects of convenient welding work, high precision, and cost-saving output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

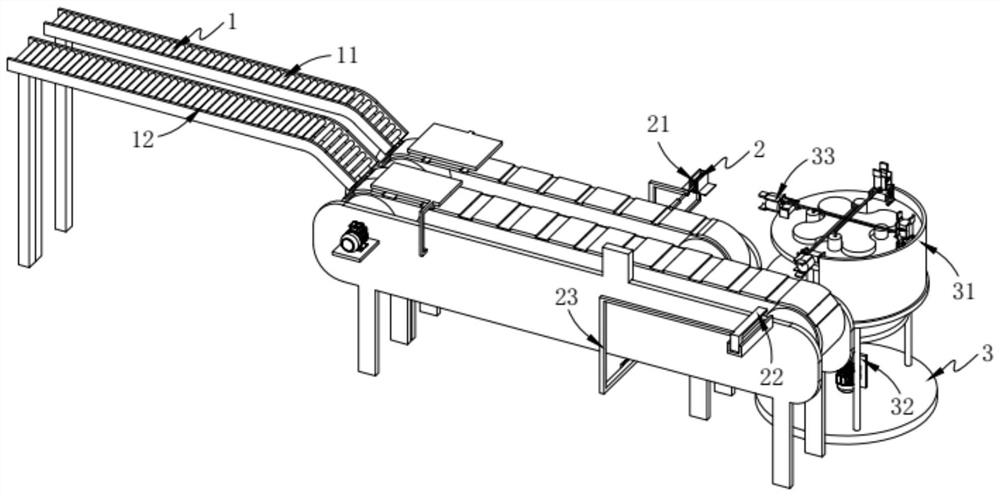

[0079] Such as figure 1 As shown, an automatic assembly equipment for air-conditioning accessories, including:

[0080] An upper loading mechanism 1, the upper loading mechanism 1 includes a first conveying assembly 11 and a second conveying assembly 12 arranged on one side of the first conveying assembly 11;

[0081] Forming mechanism 2, the forming mechanism 2 includes a drive assembly 21 fixedly arranged at the output end of the first conveying assembly 11, a discharge assembly 22 arranged at the output end of the second conveying assembly 12, and one end connected to the drive assembly 21 And the steering assembly 23 whose other end is connected to the discharge assembly 22; and

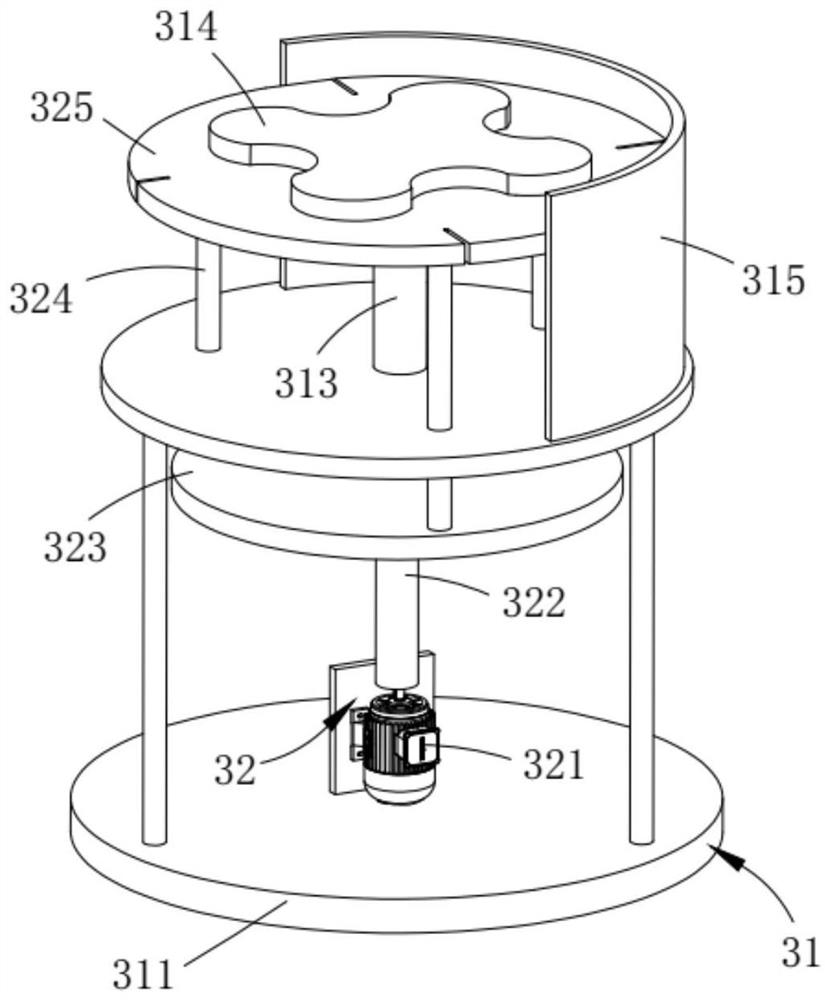

[0082] Turning mechanism 3, the turning mechanism 3 includes a support assembly 31 arranged at the output end of the first conveying assembly 11, a circular assembly 32 arranged on the support assembly 31 and a plurality of arrays along the circumferential direction of the circular assembly 32 ...

Embodiment 2

[0140] Such as Figure 10 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0141] further, such as Figure 10 As shown, the steering assembly 23 includes:

[0142] A forward component 231, the forward component 231 includes a connecting rod a232 with one end fixedly connected to the telescopic end of the cylinder 212 and a rack a233 fixedly connected with the connecting rod a232;

[0143] A retreat assembly 234, the retreat assembly 234 includes a connecting rod b235 fixedly connected to the sliding rod 222 at one end and a rack b236 fixedly connected to the connecting rod b235; and

[0144] A gear 237, the gear 237 is rotatably disposed on the bottom of the frame b1221 and the gear 237...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com