Gas shielded welding combination trolley

A gas shielded welding and trolley technology, applied in welding accessories and other directions, can solve the problems of difficult movement of welding equipment pipelines and bridges, long integrated pipe gallery lines, time-consuming and inconvenient, etc., to achieve rapid completion of welding work, strong mobility, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

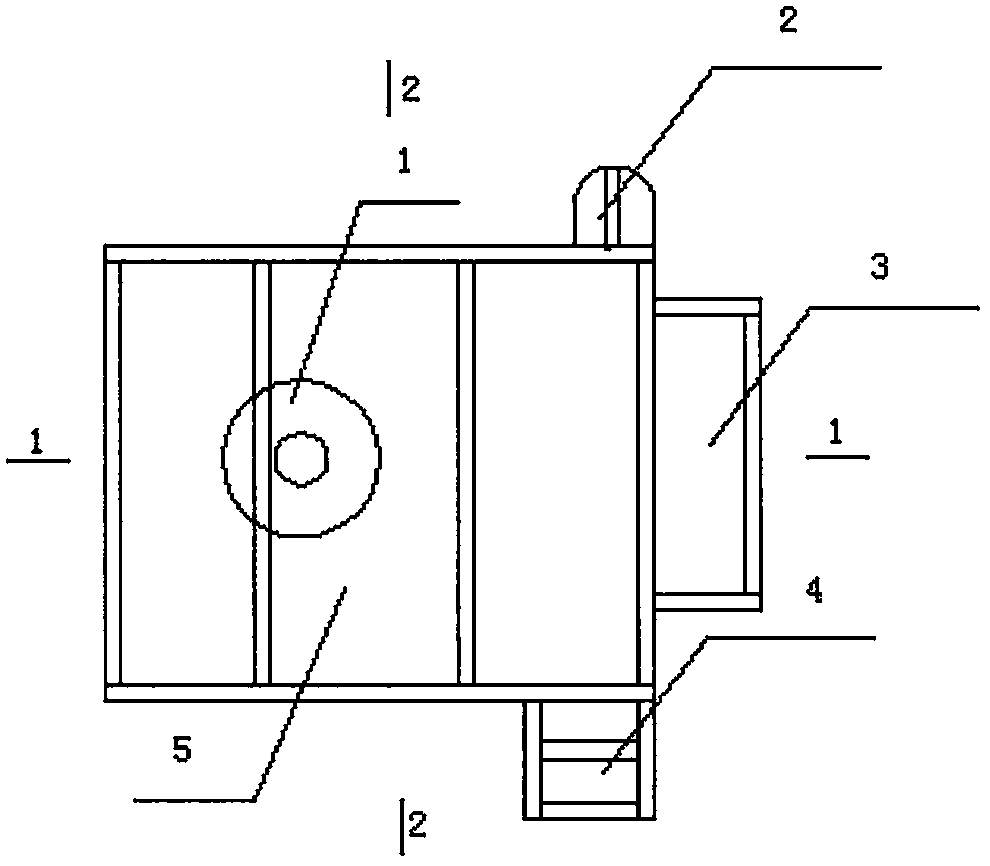

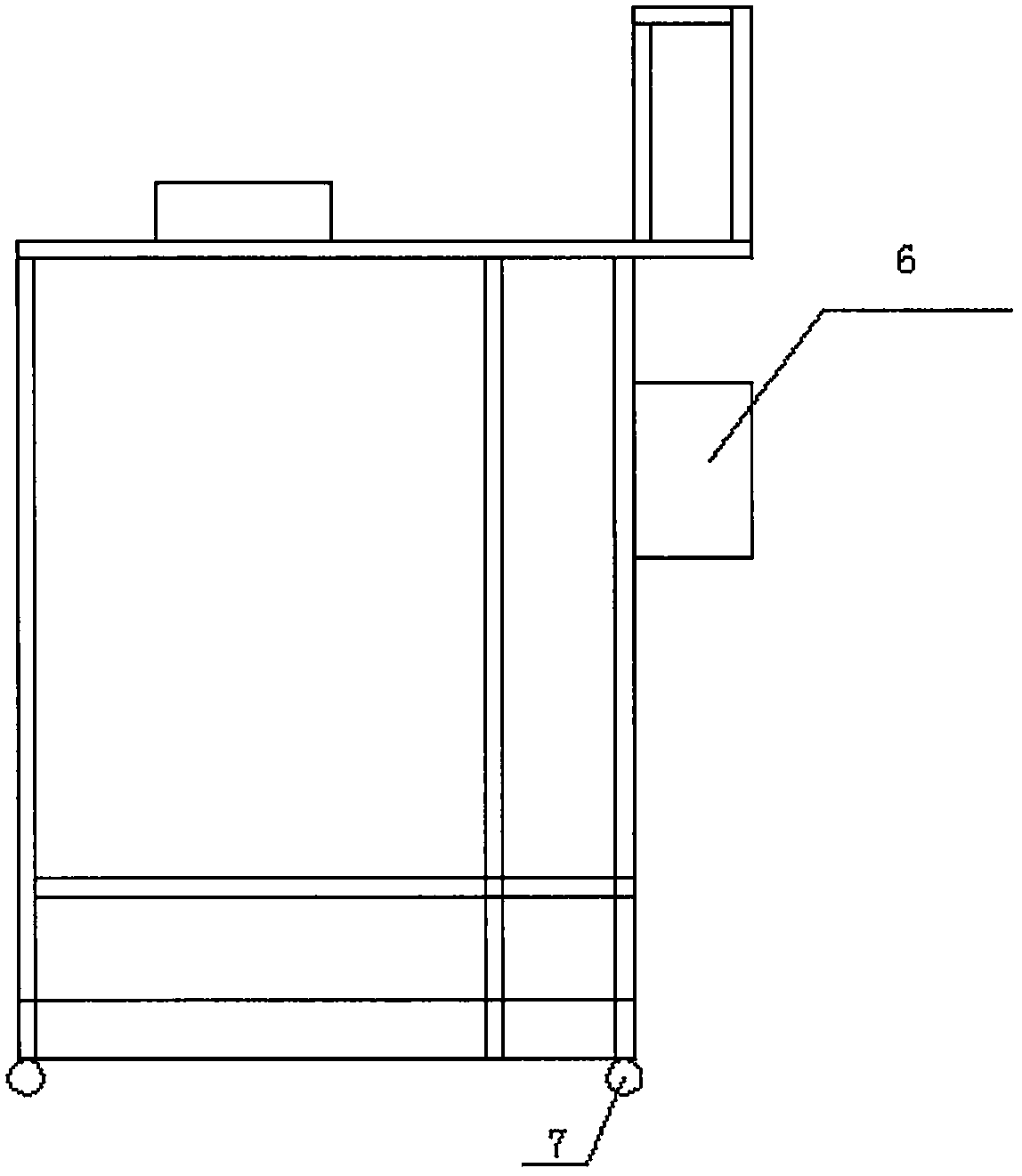

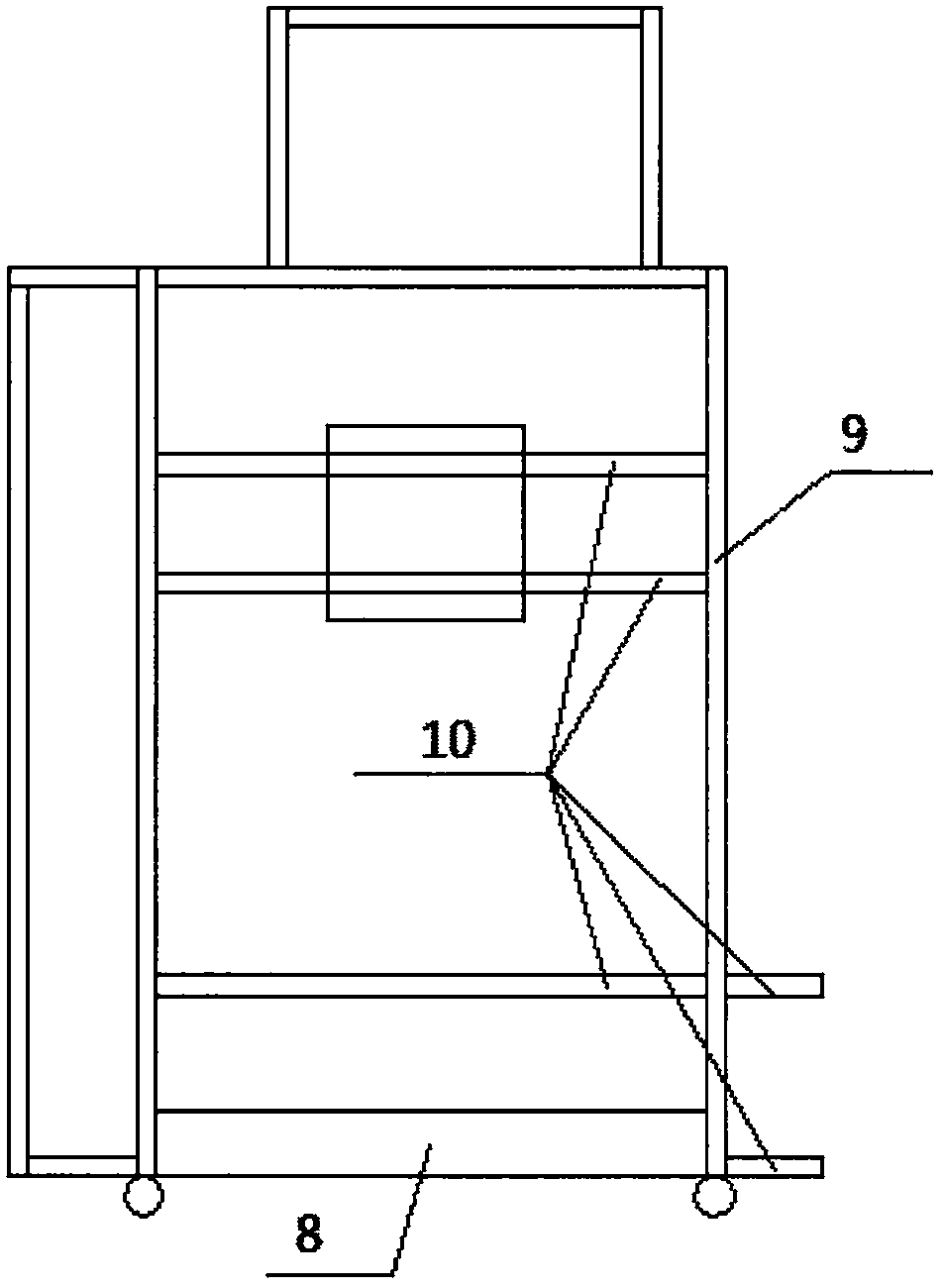

[0014] Such as figure 1 , 2 As shown in 3, the gas shielded welding combination trolley includes frame, cable (wire) storage tray 1, fire extinguisher storage rack 2, switch box storage rack 3, acetylene storage rack 4, electric welding machine storage rack 5, tool box 6, rollers 7. Steel plate toe board 8, the four corners of the bottom of the frame are provided with rollers, the frame is provided with an upper table, and the upper table is provided with an electric welding machine placement frame, and the center line of the upper table is provided with a cable (line ) A storage tray, the right front of the frame is provided with an acetylene placing rack, the left front of the frame is provided with a fire extinguisher placing rack, and the front of the frame is provided with a switch box placing rack, the switch A tool box is fixedly connected with the vehicle frame under the box placement frame, and four sides of the bottom end of the vehicle frame are provided with foot gua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com