Welding tool clamp

A welding fixture and carrier technology, applied in the field of welding fixtures, can solve problems such as complex structure, large space occupation, and slow clamping speed, so as to improve work efficiency, ensure welding quality, and avoid slippage of weldments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

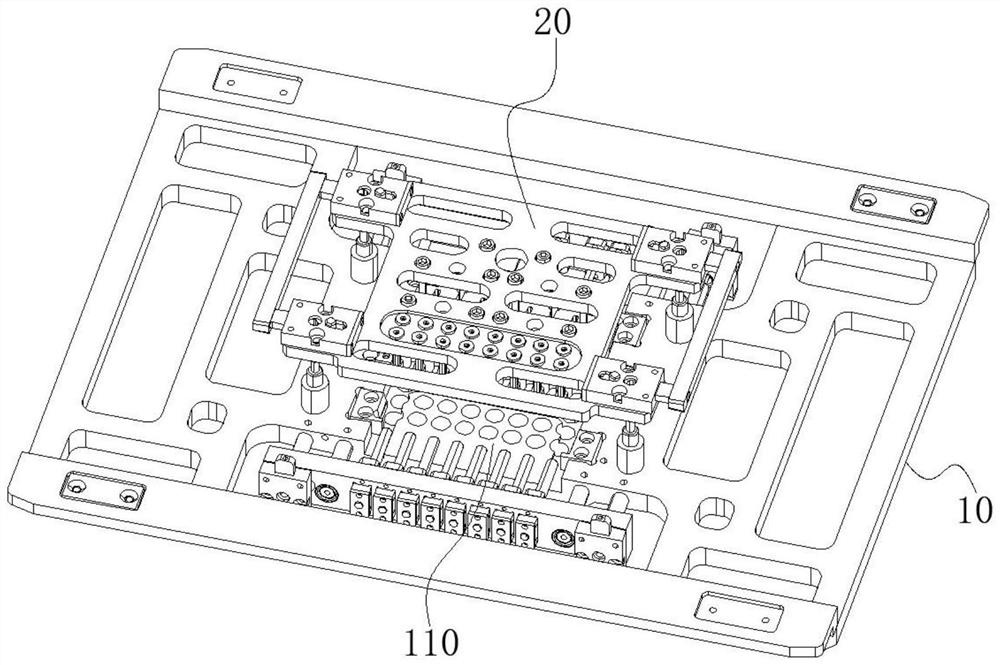

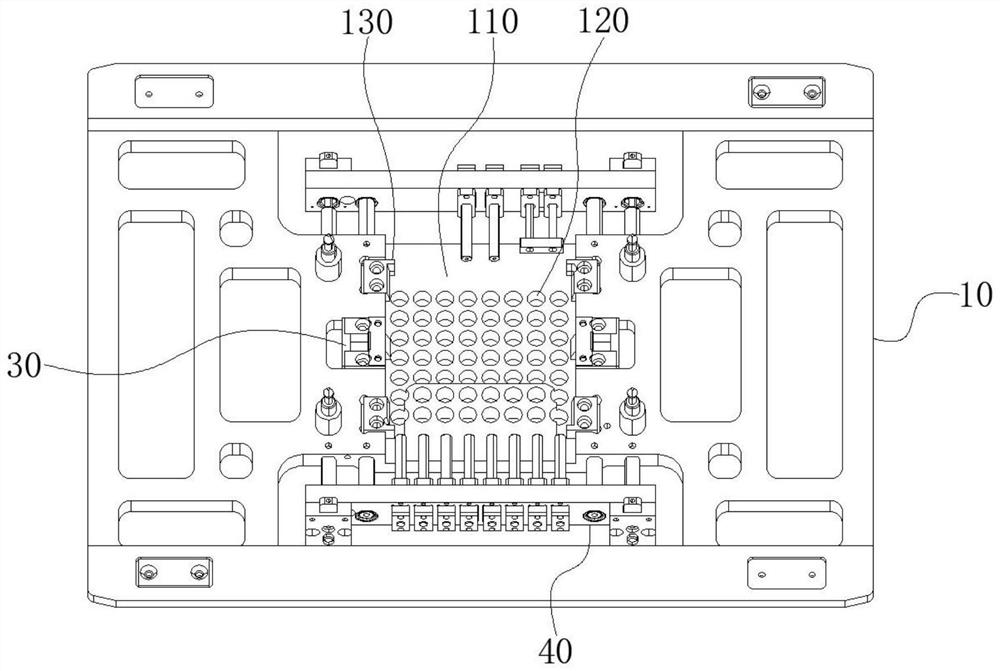

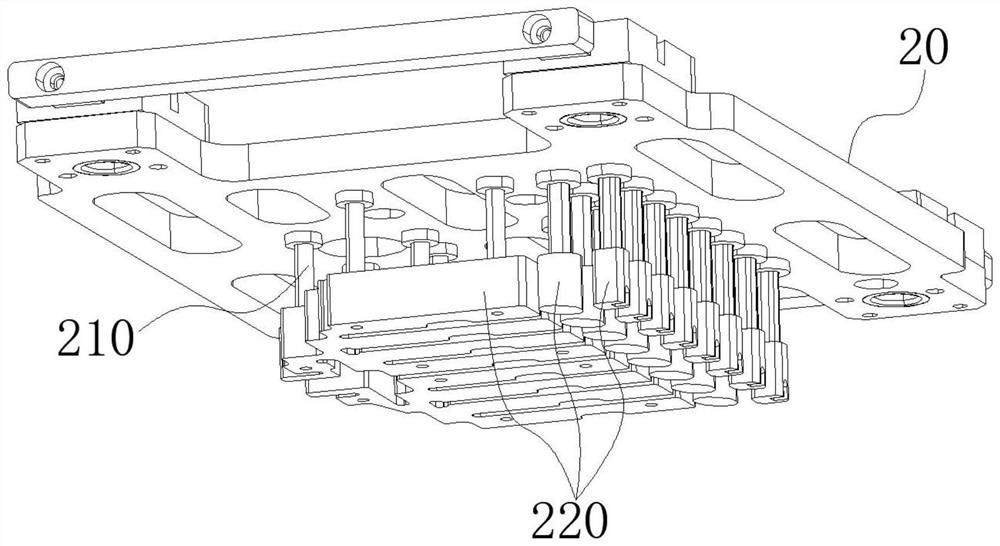

[0045] see Figure 1 to Figure 6 As shown, a welding fixture, including:

[0046] The carrier substrate 10 has an accommodating area 110 for placing weldments in its middle position, and the surface array of the carrier substrate 10 has a plurality of through holes 120 communicating with the accommodating area 110. Here, the design shape of the accommodating area is actually according to The size of the weldment is adjusted to ensure that the weldment can be completely placed in the accommodating area, and the through hole design on the surface of the carrier substrate is to facilitate the subsequent furnace passing ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com