TO-CanLD assembly without backlight monitoring, and preparation method thereof

A backlight and component technology, applied in the laser field, can solve the problems of affecting the quality stability of laser products, affecting the use efficiency, and increasing the temperature drift coefficient, so as to increase the quality stability, avoid the falling off of the coating, and ensure the effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

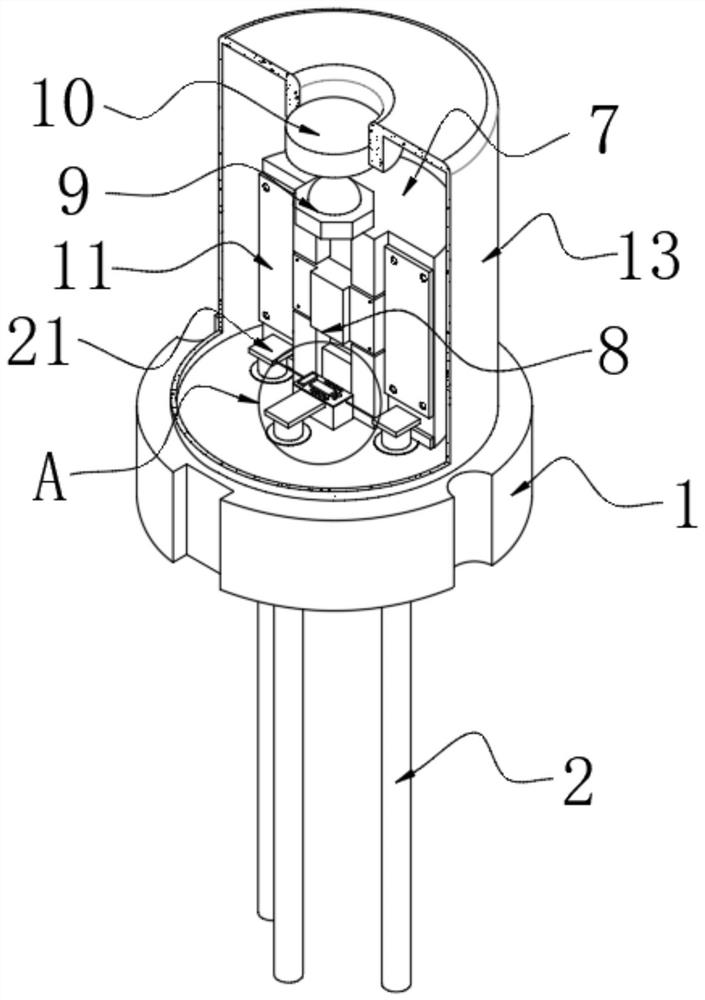

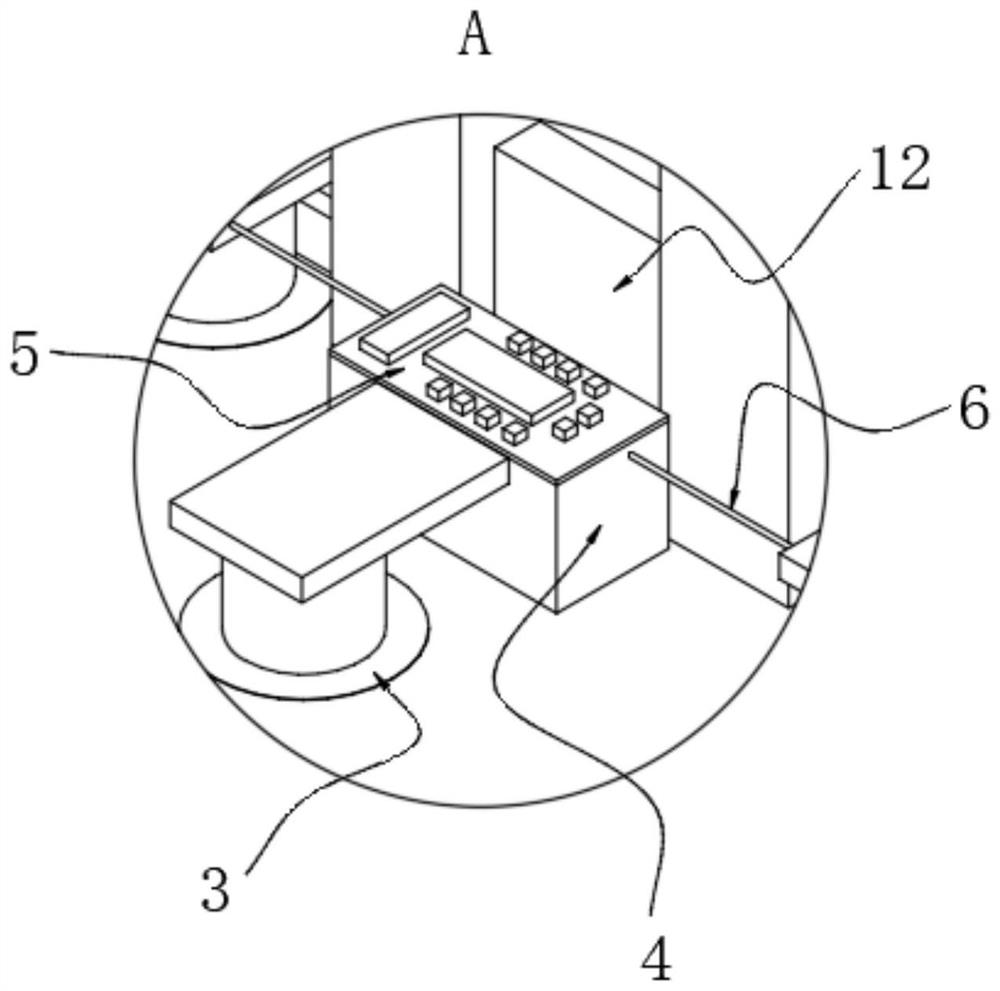

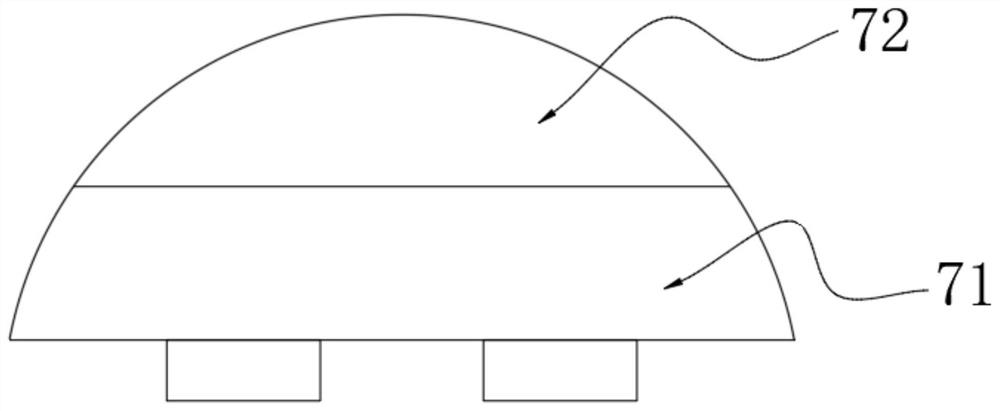

[0035] see Figure 1-4 , TO-CanLD component without backlight monitoring, including TO base 1, pin 2, pin positioning block 21, insulating sleeve 3, detection chip pad 4, backlight detector 5, bonding gold wire 6, heat sink 7, Heat dissipation layer 71, rear cover layer 72, water inlet cavity 73, guide cavity 74, water diversion cavity 75, first connection hole 76, second connection hole 77, transition cavity 78, drainage groove 79, third connection hole 710, Water outlet cavity 711, semiconductor laser 8, beam shaping system 9, lens optical system 10, semiconductor cooling chip 11, thermistor 12, TO tube cap 13.

[0036] The positions and connections of the above structures are as follows:

[0037]The inside of the TO base 1 is fixedly connected with the pin 2, the top of the TO base 1 is fixedly connected with the detection chip spacer 4, the top of the detection chip spacer 4 is fixedly connected with the backlight detector 5, the backlight detector 5 and the pin 2 is con...

Embodiment 2

[0049] A method for preparing a TO-CanLD component without backlight monitoring, comprising the following steps:

[0050] S1. Make the TO base 1, and open a connection hole for installing the pin 2 on the TO base 1. The inner diameter of the connection hole matches the insulation sleeve 3, and the insulation sleeve 3 and the connection hole are interference fit;

[0051] S2, making the heat sink 7, the heat dissipation layer 71 and the back cover layer 72 of the heat sink 7 are integrally processed and formed, and the material of the heat dissipation layer 71 and the back cover layer 72 is nickel-based alloy powder, which is formed by 3D printing;

[0052] S3, fuse the heat sink 7 made in S2 with the TO base 1, and adjust the heat sink 7 to be perpendicular to the top surface of the TO base 1;

[0053] S4, adopt LD chip as the chip of semiconductor laser 8, adopt PD chip as the chip of backlight detector 5, make pin 2 and its pin positioning block 21, make detection chip space...

Embodiment 3

[0060] A method for preparing a TO-CanLD component without backlight monitoring, comprising the following steps:

[0061] S1. Make the TO base 1, and open a connection hole for installing the pin 2 on the TO base 1. The inner diameter of the connection hole matches the insulation sleeve 3, and the insulation sleeve 3 and the connection hole are interference fit;

[0062] S2, making the heat sink 7, the heat dissipation layer 71 and the rear cover layer 72 of the heat sink 7 are integrally processed and formed, and the materials of the heat dissipation layer 71 and the rear cover layer 72 are tungsten-copper alloy powder, which are formed by 3D printing;

[0063] S3, fuse the heat sink 7 made in S2 with the TO base 1, and adjust the heat sink 7 to be perpendicular to the top surface of the TO base 1;

[0064] S4, adopt LD chip as the chip of semiconductor laser 8, adopt PD chip as the chip of backlight detector 5, make pin 2 and its pin positioning block 21, make detection chip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com