Radish batch dicing device for food production

A radish and batch technology, which is applied to the field of batch dicing equipment for radish for food production, can solve the problems of increasing the workload of dicing radish, failing to achieve automatic transmission, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

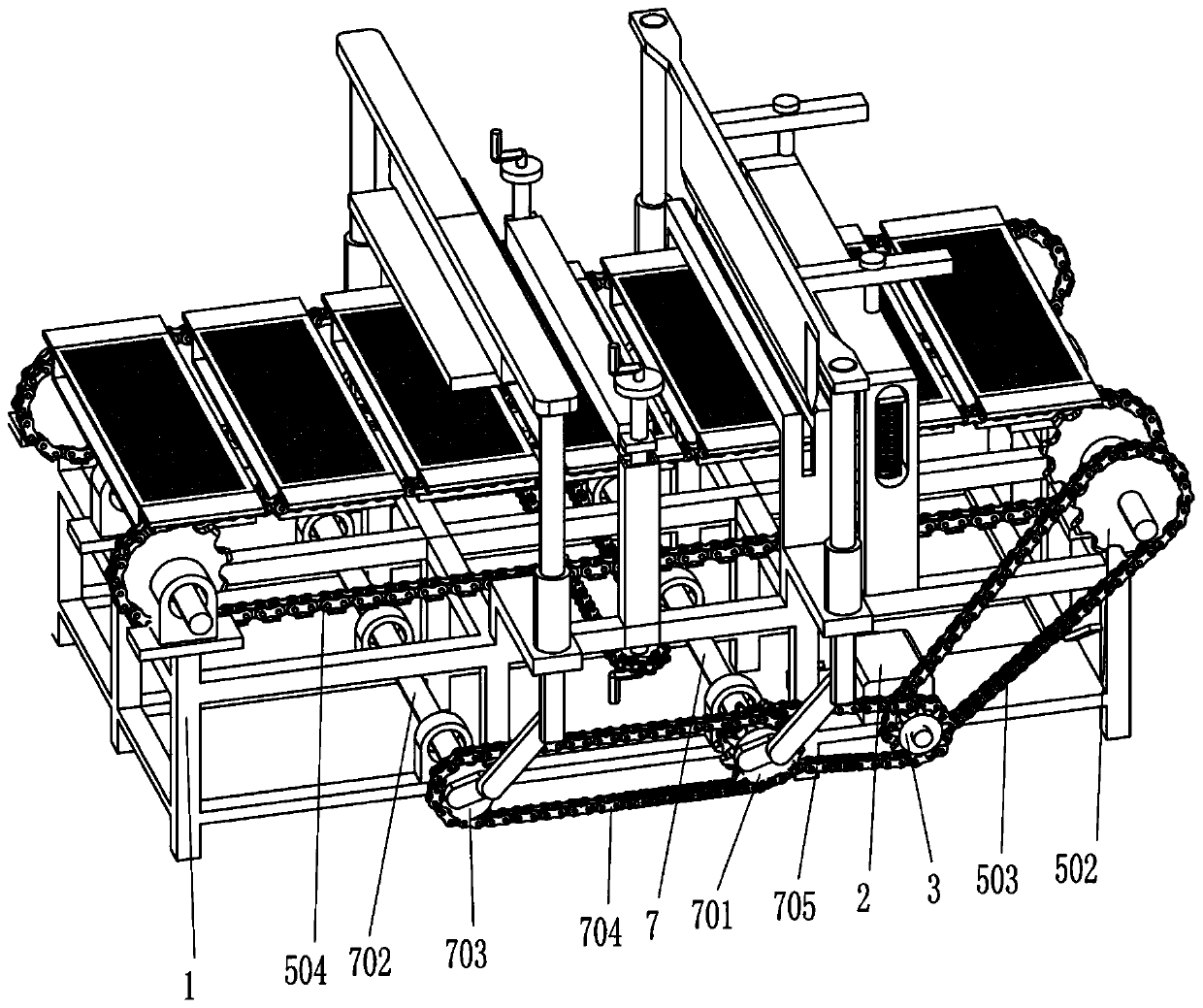

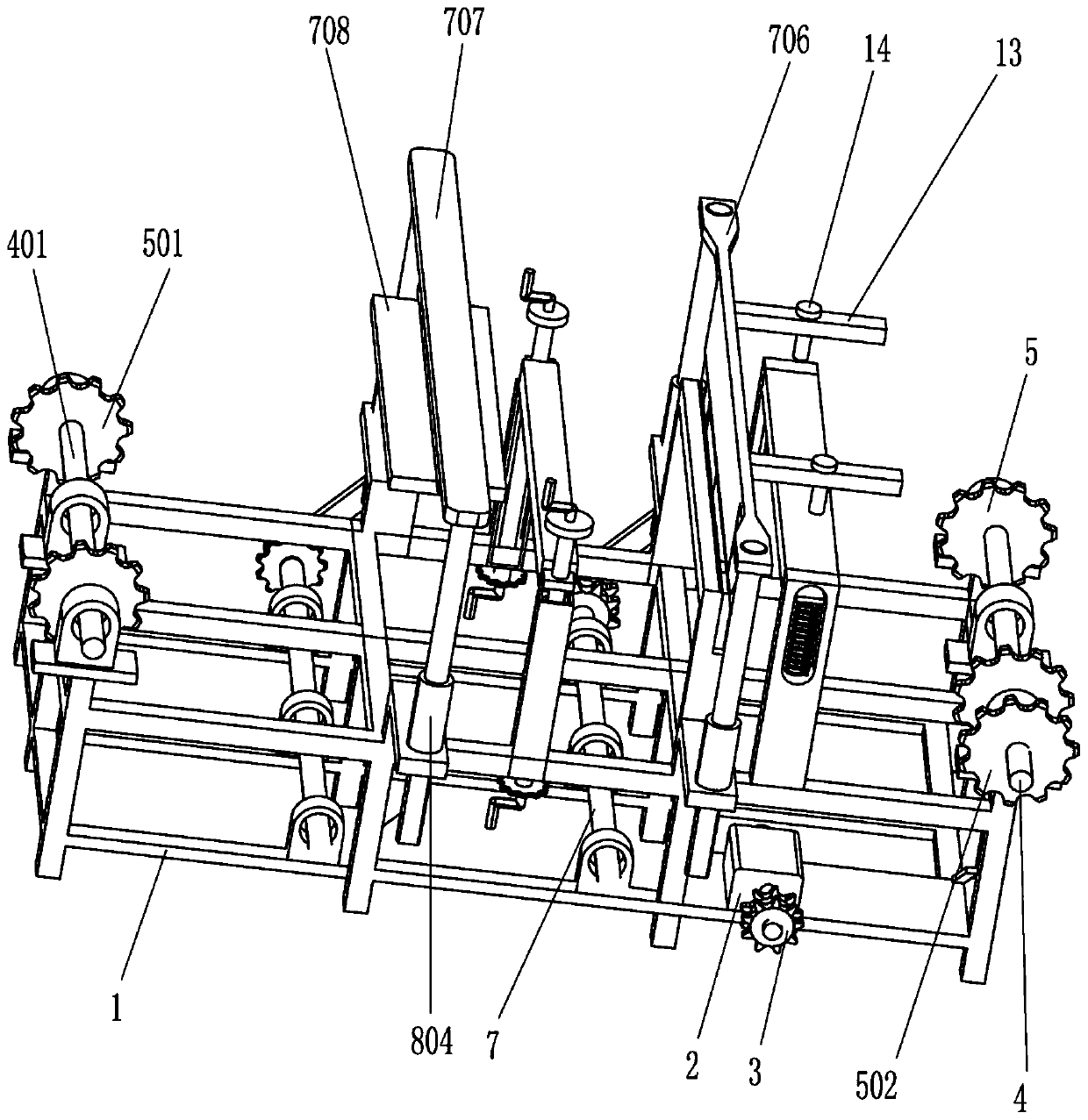

[0069] A kind of radish batch dicing equipment for food production, such as Figure 1-6 Shown, include frame 1, motor 2, double sprocket one 3, rotating shaft one 4, single sprocket one 5, rotating shaft two 401, single sprocket two 501, single sprocket three 502, chain one 503 and chain two 504, the motor 2 is fixed on the top of the frame 1, the double sprocket-3 is fixed on the output shaft of the motor 2, the rotating shaft-4 is connected to the right end of the frame 1 in rotation, and the two single sprockets-5 are symmetrically fixed on the rotating shaft-4 , rotating shaft 2 401 is rotatably connected to the left end of frame 1, two single sprockets 2 501 are symmetrically fixed to rotating shaft 2 401, single sprocket 3 502 is fixed to the end of rotating shaft 1 4, and single sprocket 3 502 is located on the single sprocket In front of one 5, chain one 503 winds around double sprocket one 3 inner wheel and single sprocket three 502, two chains two 504 wind around sin...

Embodiment 2

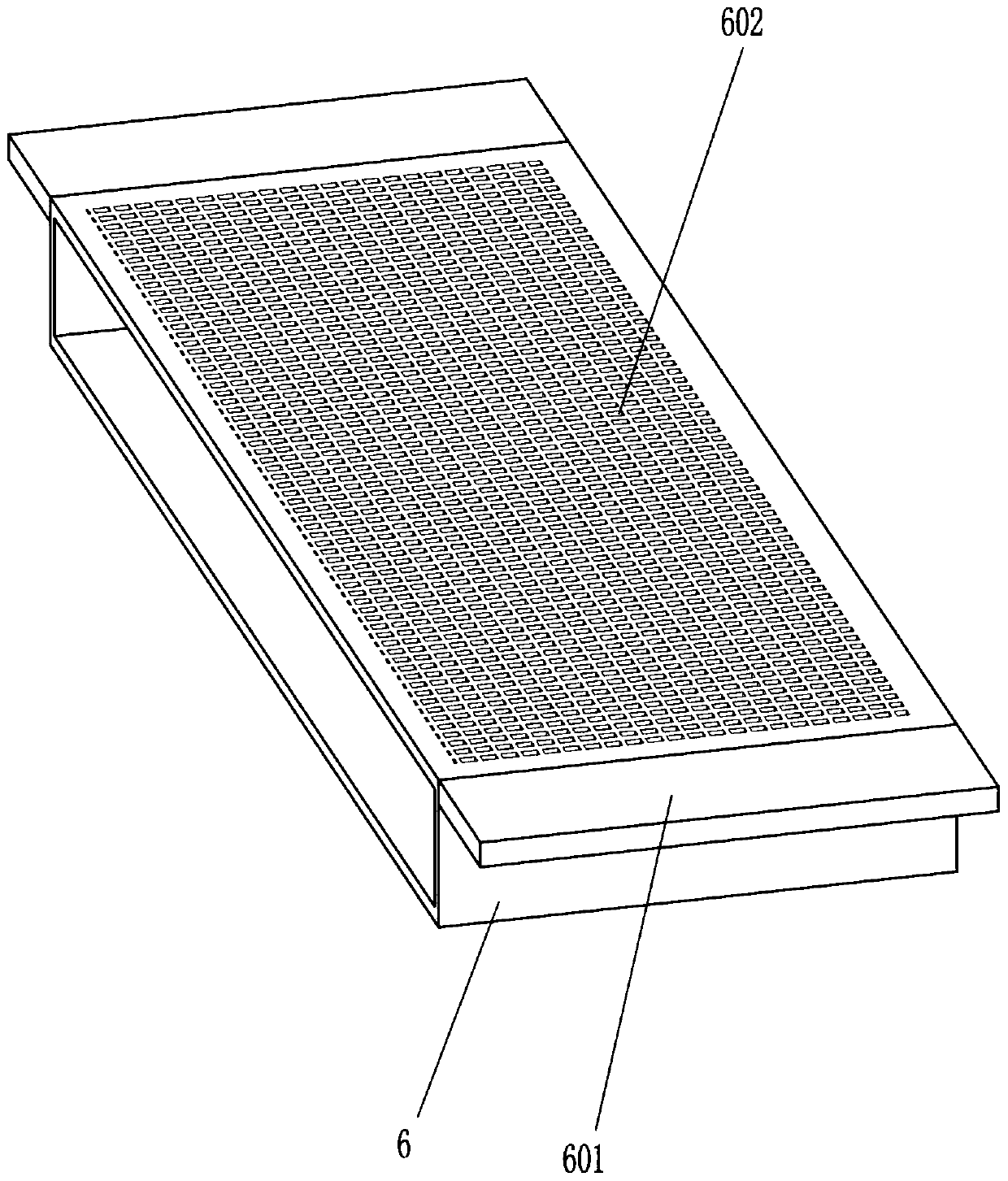

[0072] On the basis of Example 1, such as Figure 2-4 As shown, the cutter set includes a collection disc 6 , a flat plate 601 and a net cutter disc 602 , the net cutter disc 602 is fixed above the collection disc 6 , and the net cutter disc 602 is located between the two flat plates 601 .

[0073] Manually put the radish on the net cutter head 602, start the motor 2 to reverse, and the chain two 504 drives the plate 601 to move from right to left through the connecting piece, thereby driving the radish slices on the net cutter head 602 to move from right to left, when the chain When the second 504 drives the radish slices on the net cutter head 602 to move to the bottom of the pressing assembly, the pressing assembly parts drive the linkage mechanism to move downward, and the pressing assembly parts press down on the radish slices, and the radish slices are cut into pieces by the net cutter head 602. Diced radish, the cut diced radish falls into the collection tray 6, realizi...

Embodiment 3

[0081] On the basis of Example 2, such as Figure 5-6 As shown, it also includes a Tangping assembly. The Tangping assembly includes a bracket 9, a screw rod 901, a rocker 902, a single sprocket 5 903, a chain 5 904 and a movable plate 905. The two brackets 9 are symmetrically fixed on the frame 1 Above, two screw rods 901 are rotatably connected to the bracket 9, two pairs of crank handles 902 are fixedly connected to both ends of the screw rod 901 respectively, and two single sprockets 903 are symmetrically fixed below the screw rod 901, and the single sprocket 5 903 is located below the bracket 9 , the chain five 904 winds around two single sprockets five 903, and the movable plate 905 is threadedly connected to the ends of the two screw rods 901.

[0082] When the chain 2 504 drives the radish slices on the net cutter head 602 to move below the movable plate 905, one of the rocking handles 902 is manually shaken, and the rocking handle 902 drives the screw 901 to rotate, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com