Method for erecting scaffold platform between rudder horns and method for measuring deviation of upper and lower rudder holes of rudder horns

A measurement method and scaffolding technology, applied in the direction of berth, ship design, ship parts, etc., can solve the problems that affect the efficiency of the hoisting progress of the berth and occupy the large door crane of the berth, so as to reduce the use time, reduce labor, and improve the progress efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

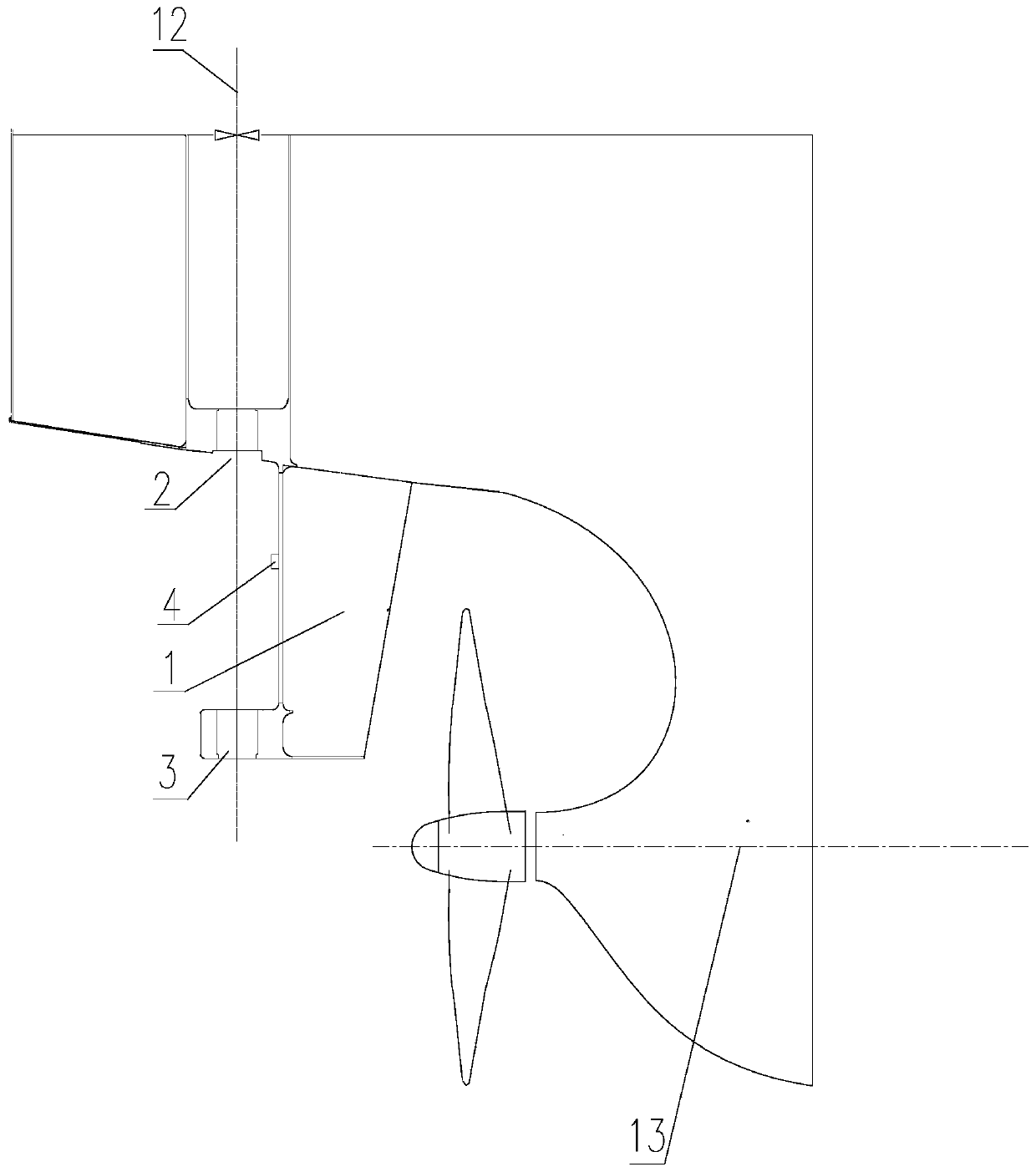

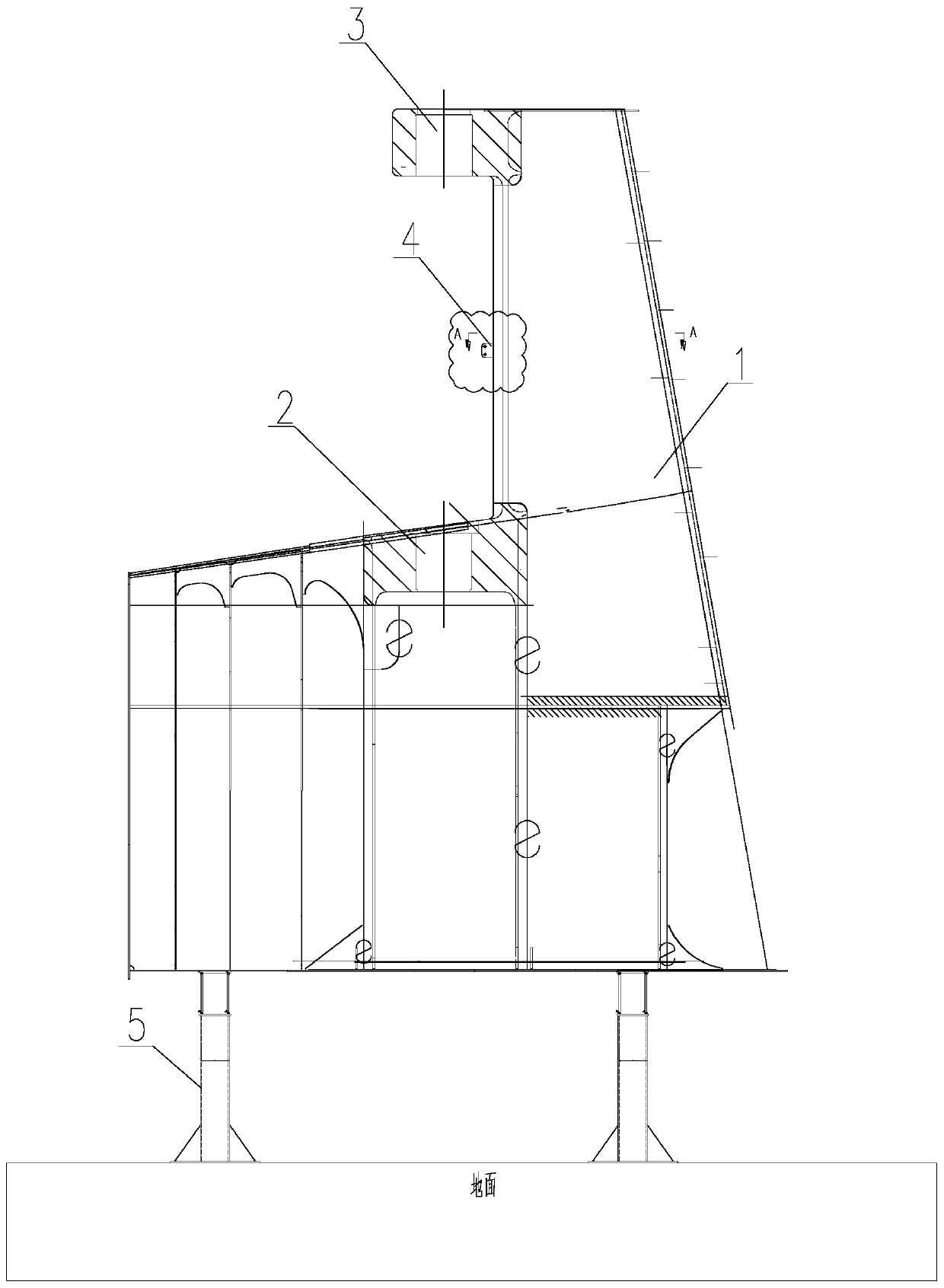

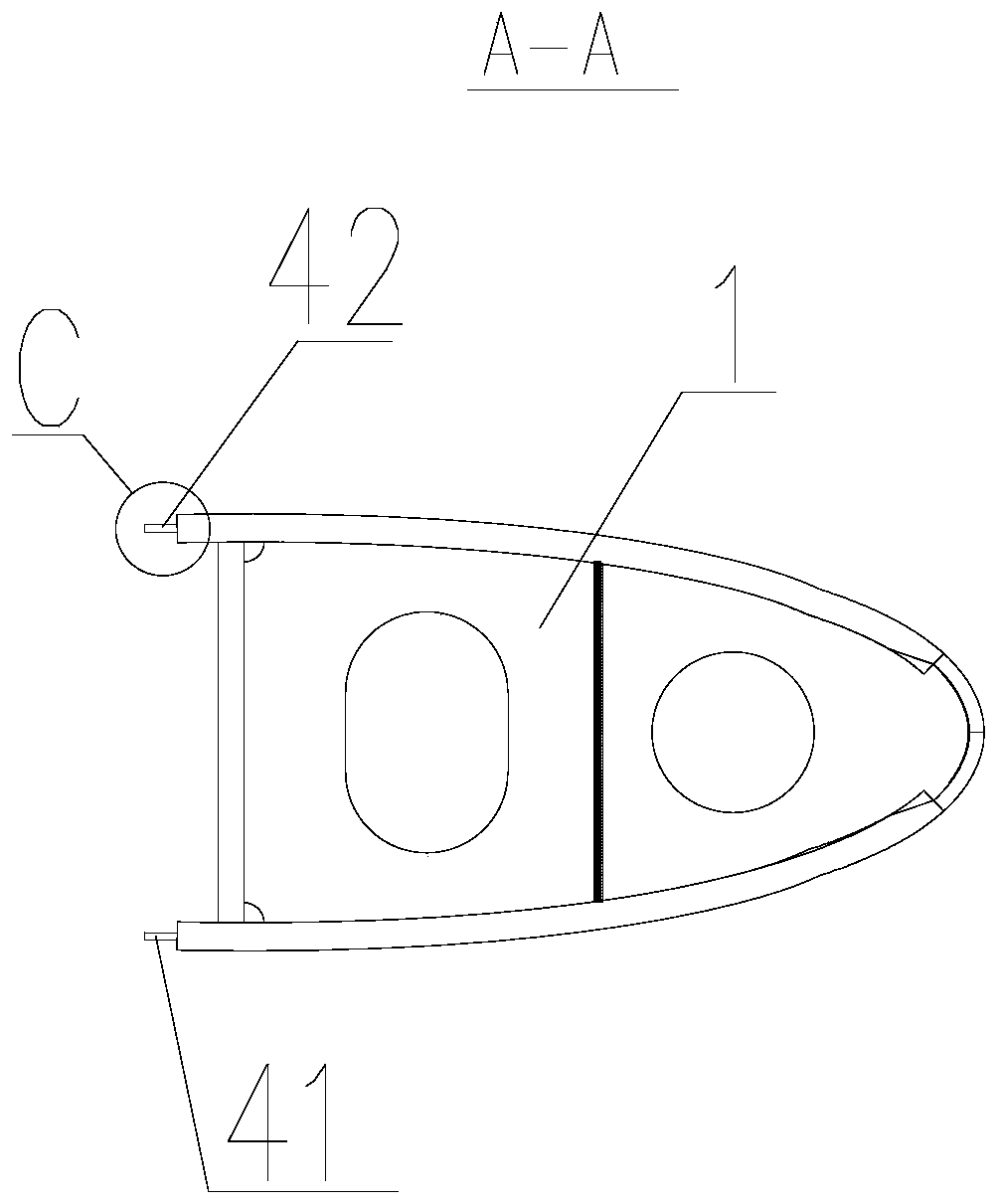

[0049] like Figure 1-13 As shown, a method for erecting a scaffolding platform between hanging rudder arms comprises the following steps:

[0050] (1) In the segmental reverse construction stage of the rudder system, the rudder system is placed on the segmented pier 5 on the ground, and the scaffold eye plate 4 is welded on the hanging rudder arm 1, and the scaffold eye plate is located on the inverted rudder arm Between the lower rudder hole 3 and the upper rudder hole 2, the scaffold eye plate 4 is set inclined to the direction of the upper rudder hole of the rudder arm;

[0051] (2) The rudder system enters the painting room in sections for paint spraying;

[0052] (3) After the rudder system section leaves the painting room, the ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com