Efficient cleanup additive for continental facies shale and preparation method of efficient cleanup additive

A drainage aid and shale technology, which is applied in the field of oil field fracturing fluid, can solve the problems that are difficult to meet the development problems of continental shale, and achieve the effects of reducing capillary resistance, reducing surface and interfacial tension, and increasing contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

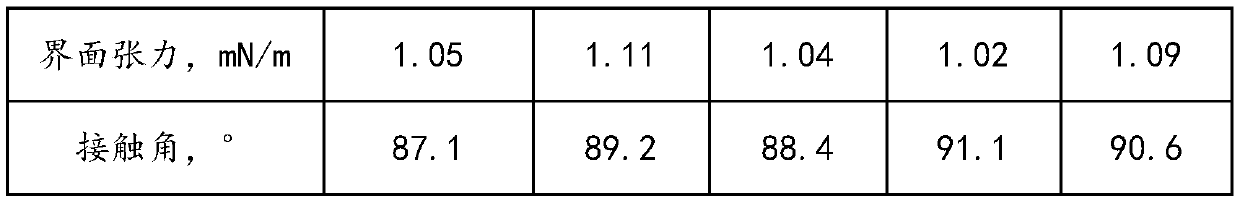

Examples

Embodiment 1

[0014] The feed mass ratio is fluorocarbon surfactant, hydrocarbon surfactant and fluorosilane surfactant feed mass ratio=2:5:8.

[0015] Among them, the fluorocarbon surfactant adopts perfluorohexyl polyvinyl ether sulfonate; the fluorosilicon surfactant adopts N-dimethylaminopropyl-N-triethoxysilane; the hydrocarbon surfactant adopts eighteen Alkyl dihexyl betaine.

[0016] Add a certain amount of hydrocarbon surfactants, fluorocarbon surfactants and fluorosilane surfactants in proportion, and stir evenly to obtain a drainage aid.

Embodiment 2

[0018] The feed mass ratio is fluorocarbon surfactant, hydrocarbon surfactant and fluorosilane surfactant feed mass ratio=2:6:9.

[0019] Among them, the fluorocarbon surfactant adopts perfluorohexyl polyvinyl ether sulfonate; the fluorosilicon surfactant adopts N-dimethylaminopropyl-N-triethoxysilane; the hydrocarbon surfactant adopts eighteen Alkyl dihexyl betaine.

[0020] Add a certain amount of hydrocarbon surfactants, fluorocarbon surfactants and fluorosilane surfactants in proportion, and stir evenly to obtain a drainage aid.

Embodiment 3

[0022] The feed mass ratio is fluorocarbon surfactant, hydrocarbon surfactant and fluorosilane surfactant feed mass ratio=3:7:8.

[0023] Among them, the fluorocarbon surfactant adopts perfluorohexyl polyvinyl ether sulfonate; the fluorosilicon surfactant adopts N-dimethylaminopropyl-N-triethoxysilane; the hydrocarbon surfactant adopts eighteen Alkyl dihexyl betaine.

[0024] Add a certain amount of hydrocarbon surfactants, fluorocarbon surfactants and fluorosilane surfactants in proportion, and stir evenly to obtain a drainage aid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com