Efficient dehydrating paper making felt

A paper-making felt, high-efficiency technology, applied in the field of high-efficiency dehydration paper-making felt, can solve the problems of large consumption of paper sheets, low dehydration efficiency, and high moisture content of paper sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

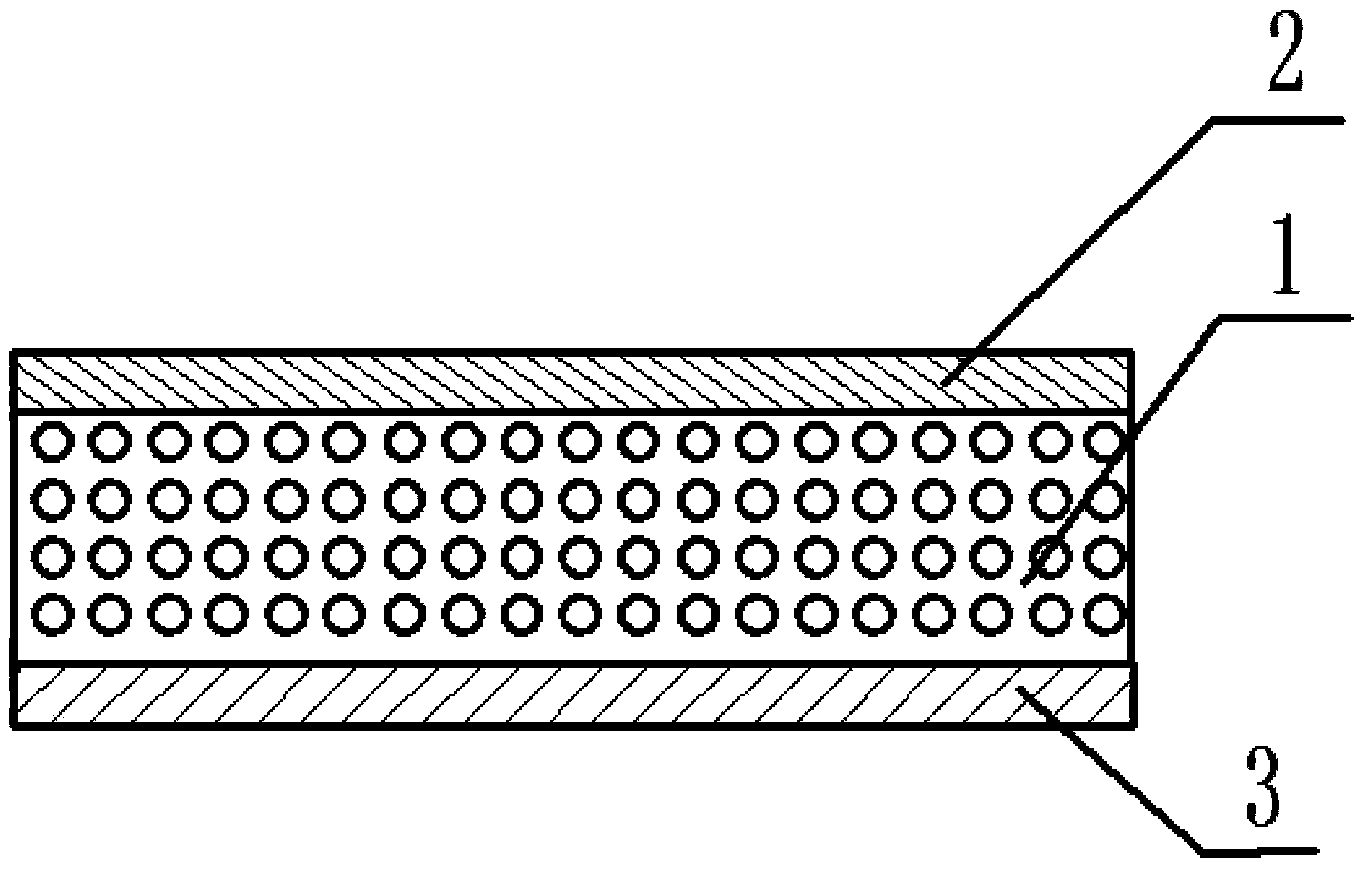

[0012] Such as figure 1 Shown: the present invention provides a kind of high-efficiency dehydration papermaking felt, mainly comprises fiber skeleton layer 1, paper surface fiber layer 2 and bottom water absorption layer 3; It is characterized in that paper surface fiber layer 2 and bottom water absorption layer 3 are all made of polyacrylic acid super Woven from absorbent fibers. The paper surface fiber layer 2 is woven from thin filaments with a diameter of 0.20-0.25mm and a filament density of 120 fibers / cm; the bottom absorbent layer 3 is woven from thick filaments with a diameter of 0.30-0.40mm. The density was 80 fibers / cm.

[0013] The fibrous skeleton layer 1, the paper fiber layer 2 and the bottom water-absorbing layer 3 are combined by a special acupuncture process, and then shaped by a hot oil roller at high temperature to make them tigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com