Anaerobic culture medium preparation system

A culture medium preparation and culture tank technology, applied in the field of culture medium, can solve the problems of easy air leakage, slow speed in anaerobic environment, etc., and achieve the effect of fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

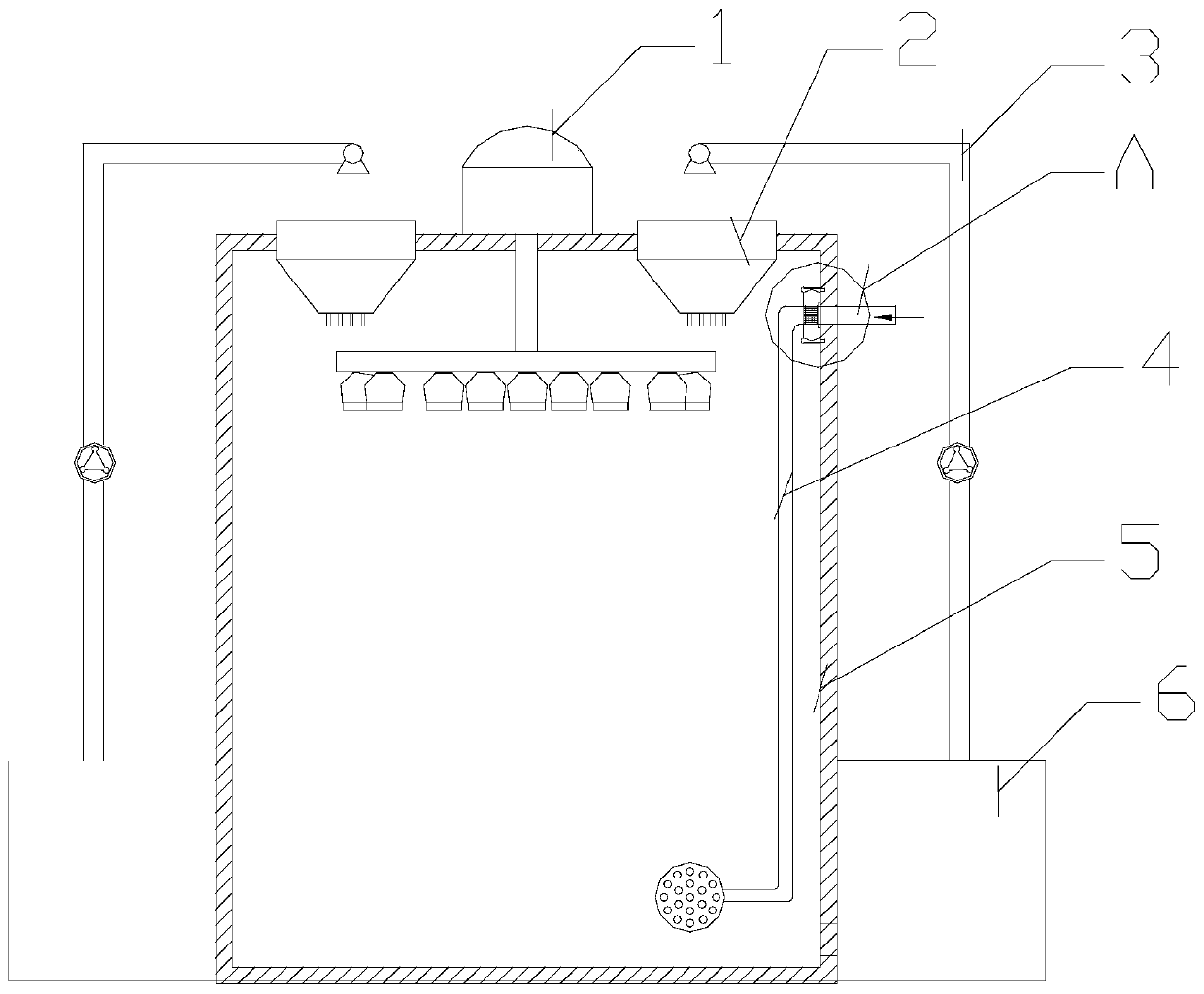

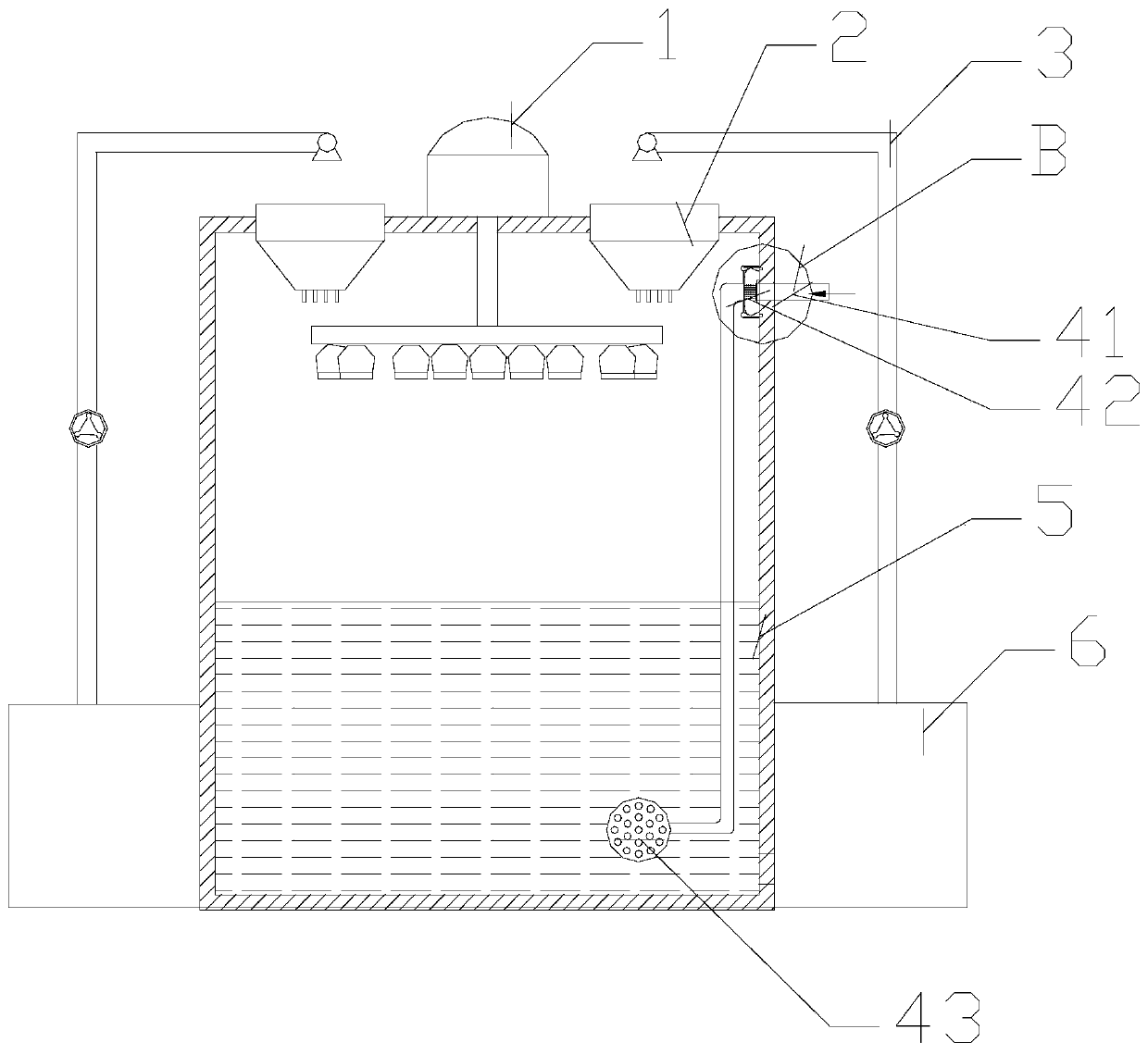

[0024] see Figure 1-Figure 3 as well as Figure 1 An anaerobic culture medium preparation system, the invention provides a kind of anaerobic culture medium preparation system, its structure comprises water level sensor 1, air outlet 2, support 3, air intake structure 4, culture tank 5, base 6, described base 6 A culture tank 5 is installed in the middle, supports 3 are installed vertically on both sides of the culture tank 5, a water level sensor 1 is installed in the middle of the top of the culture tank 5, and a water level sensor 1 is installed on the culture tank 5 on both sides of the water level sensor 1. The air outlet 2, the side top of the culture tank 5 is equipped with an air intake structure 4.

[0025] The air outlet 2 is an inverted frustum-shaped structure, and the end surface of its bottom surface is also provided with more than two air outlet pipes, that is, a structure with a wide top and a narrow bottom. When inert gas is injected to cause bubbles to occur...

Embodiment 2

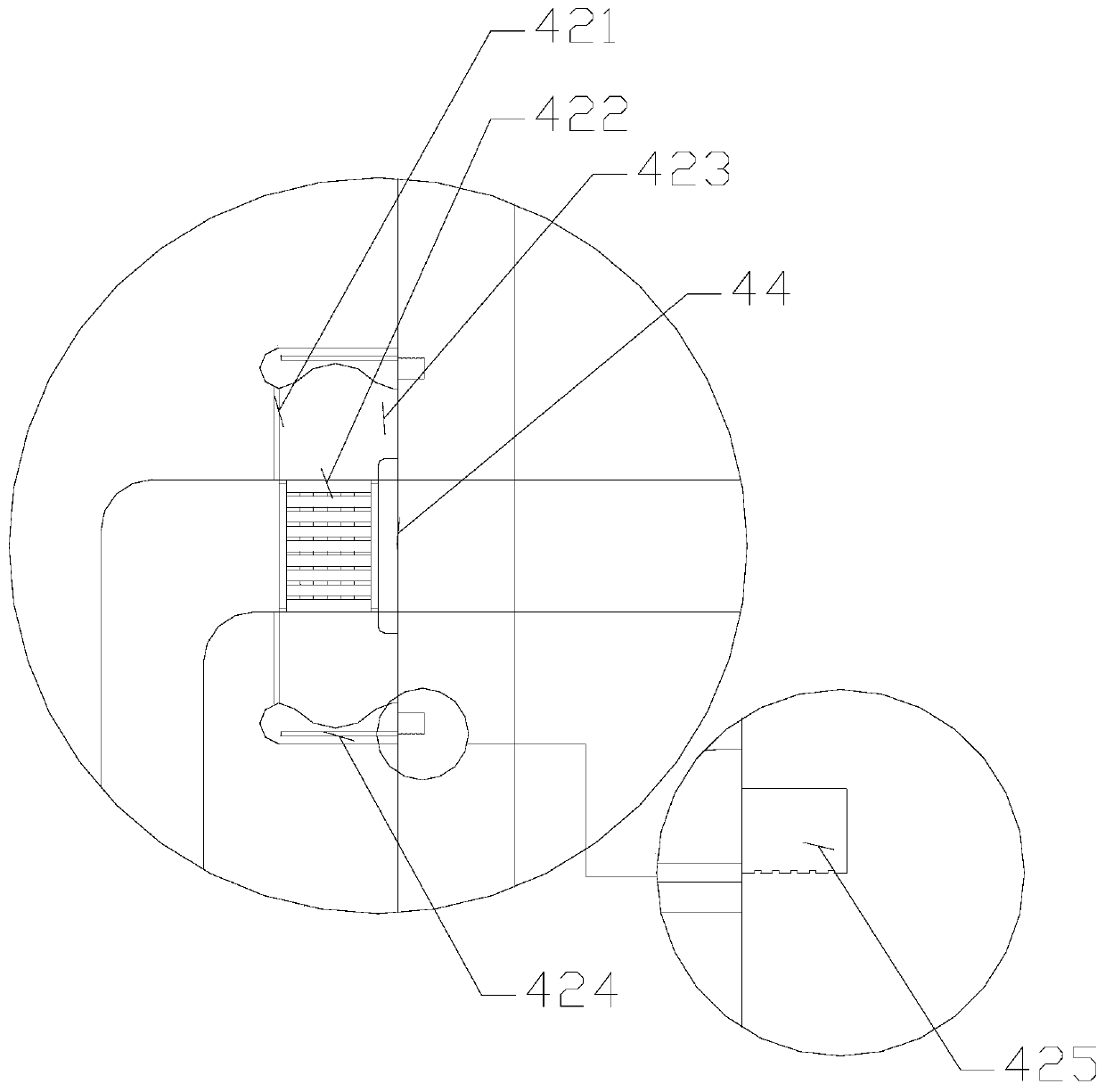

[0032] see Figure 1-Figure 5 , a kind of anaerobic medium preparation system, the present invention provides a kind of anaerobic medium preparation system, its structure comprises water level sensor 1, air outlet 2, bracket 3, air intake structure 4, culture tank 5, base 6, described A culture tank 5 is installed in the middle of the base 6, and supports 3 are vertically installed on both sides of the culture tank 5, and a water level sensor 1 is installed in the middle of the top of the culture tank 5, and the culture tank 5 on both sides of the water level sensor 1 An air outlet 2 is provided, and an air intake structure 4 is installed on the side top of the culture tank 5 .

[0033] The air outlet 2 is an inverted frustum-shaped structure, and the end surface of its bottom surface is also provided with more than two air outlet pipes, that is, a structure with a wide top and a narrow bottom. When inert gas is injected to cause bubbles to occur on the water surface of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com