Composite board with capillary tubes and forming method of composite board

A molding method and capillary tube technology, applied in the field of construction, can solve the problems of uneven temperature in the heating space, complex structure of the heating system, and low thermal efficiency, and achieve the effect of uniform and comfortable indoor temperature, high thermal efficiency, and reduced use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

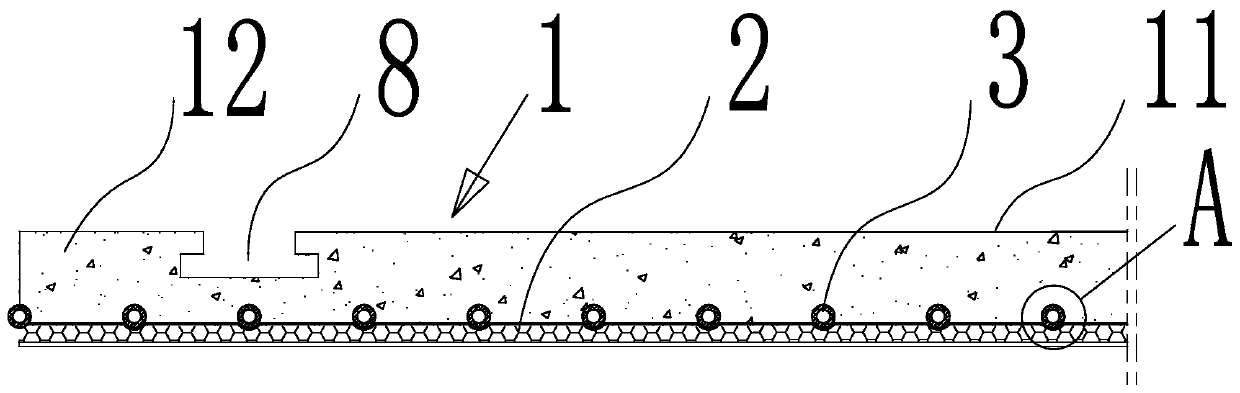

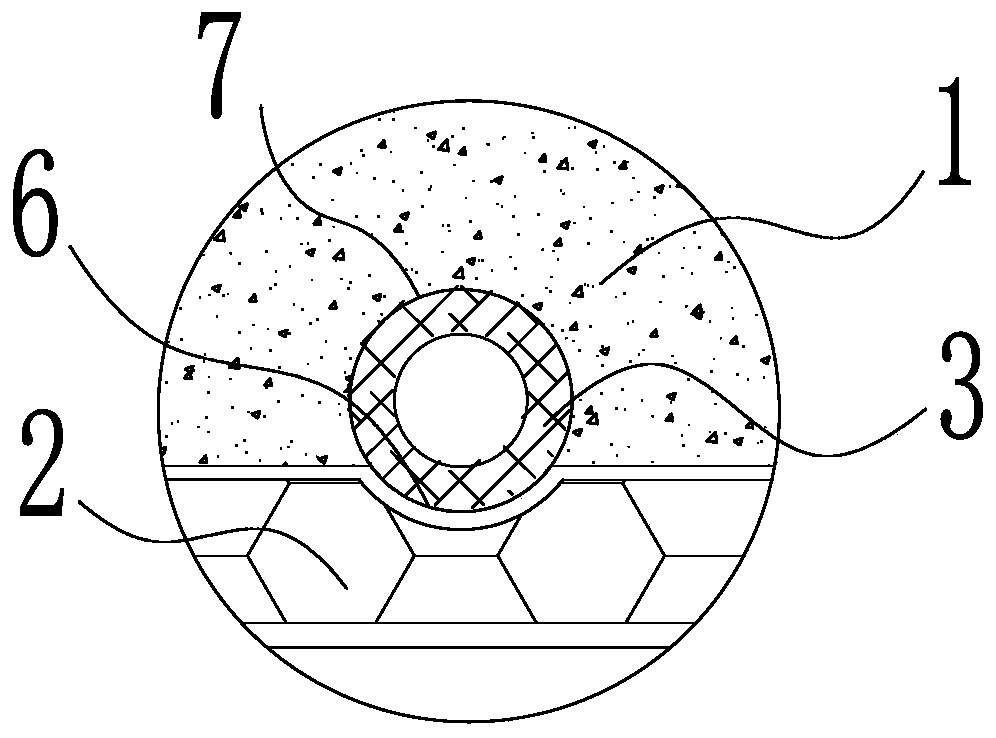

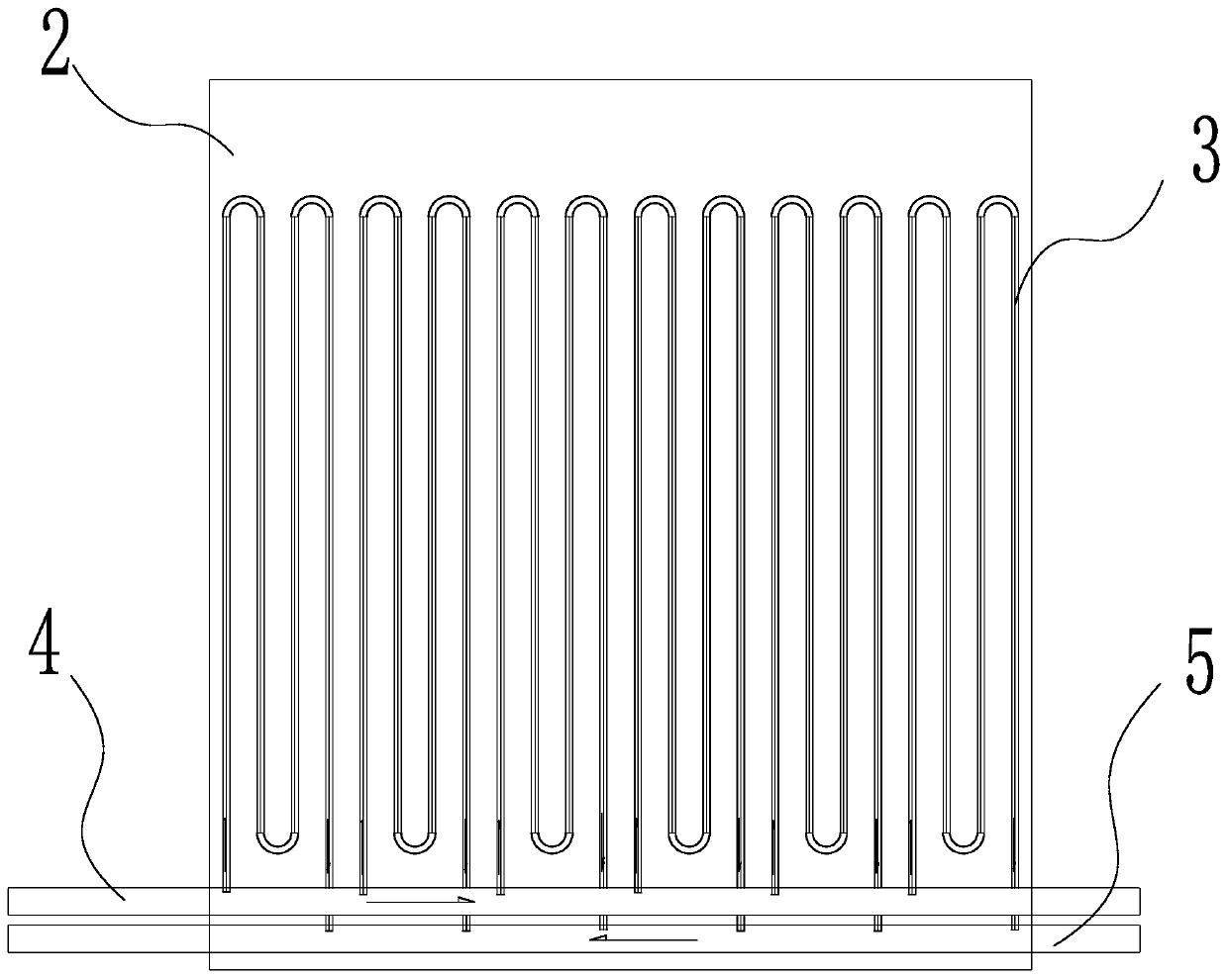

[0028] like figure 1 and figure 2 As shown, the composite panel with capillary of the present invention comprises the thermal insulation board 1 that is tiled and fixed on the ceiling, and the honeycomb metal panel 2 is tiled and fixed outside the thermal insulation board 1, and the honeycomb metal panel 2 in the present embodiment is honeycomb An aluminum plate, a number of capillary tubes 3 are sandwiched between the honeycomb metal plate 2 and the heat preservation plate 1, such as image 3 As shown, the capillary 3 is reciprocally bent to form a serpentine tube, and the capillary 3 is equally spaced along the length direction of the insulation board 1, and the corresponding honeycomb metal plate 2 and the insulation board 1 below the capillary 3 are installed in parallel with the water supply pipe. 4 and the water return pipe 5, the two ends of the capillary 3 are connected to the external temperature-adjusted water supply source through the water supply pipe 4 and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com