Blowout preventer for oil field workover treatment

A blowout preventer and workover technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of unqualified safety performance, safety accidents, inconvenient operation, etc., and achieve volume reduction and The effect of weight, enhanced safety factor, and convenient installation on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in detail below in conjunction with embodiments. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

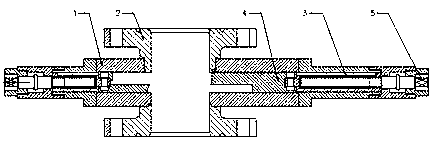

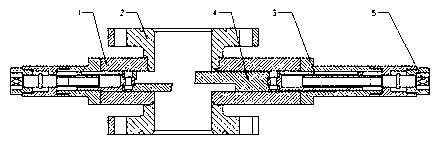

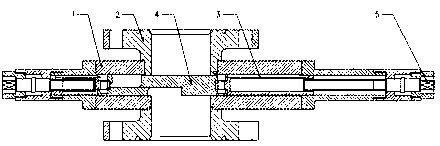

[0023] like Figure 1-3 As shown, a blowout preventer for oilfield workover operations includes a body 1, and a vertical through hole is arranged in the body 1, and the pipe string and tools can pass up and down smoothly in the vertical through hole. The upper and lower sides of the body 1 There is a flange 2 at the end, and a set of two opposite sealing rams 3 are provided for sealing and sliding in the inner cavity of the body 1, which are used to realize the full sealing of the blowout preventer or the half sealing of the blowout preventer through the change and cooperation of the relative position Function;

[0024] A rubber block 4 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com