Differential mechanism

A technology for differentials and housings, applied in differential transmissions, belts/chains/gears, mechanical equipment, etc., can solve problems such as poor working stability, achieve the goal of eliminating wear, ensuring working stability, and improving wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

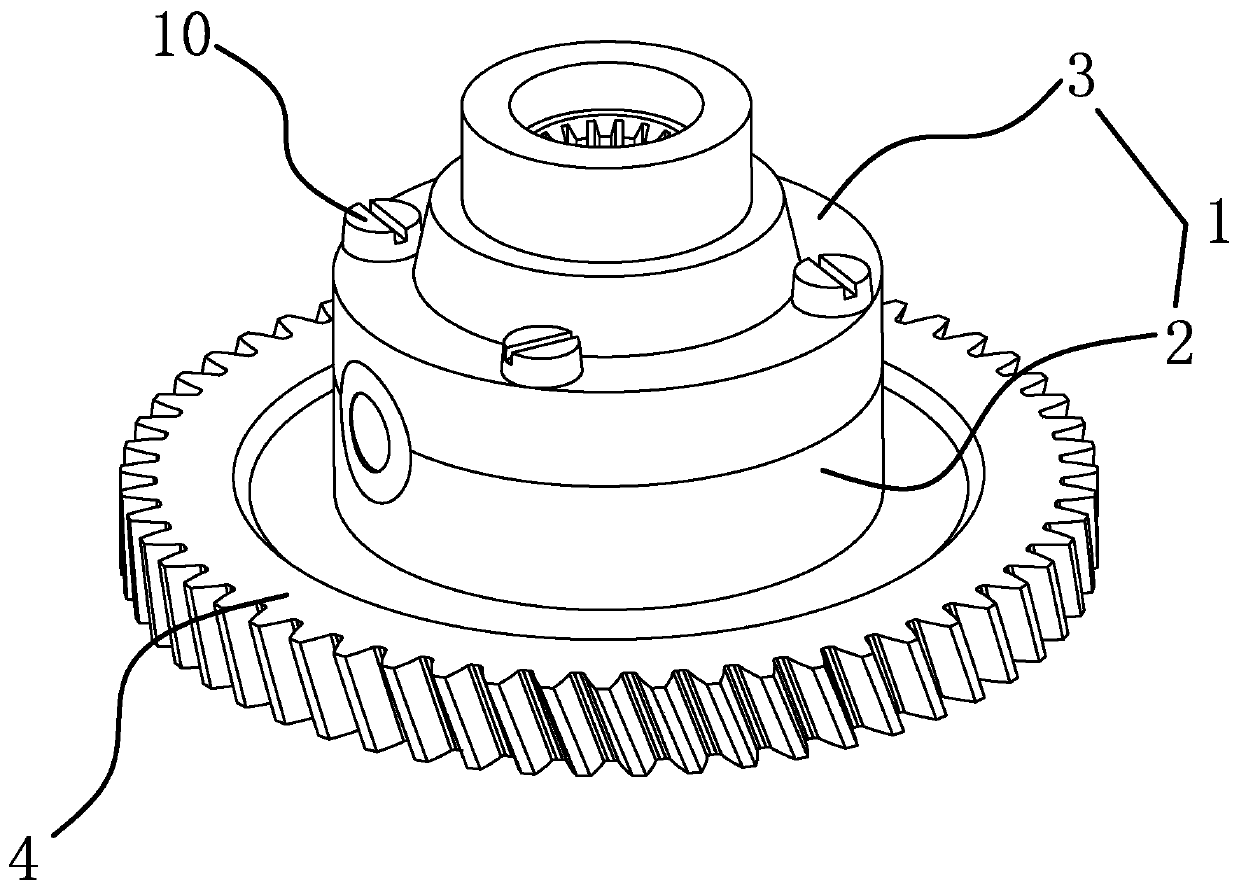

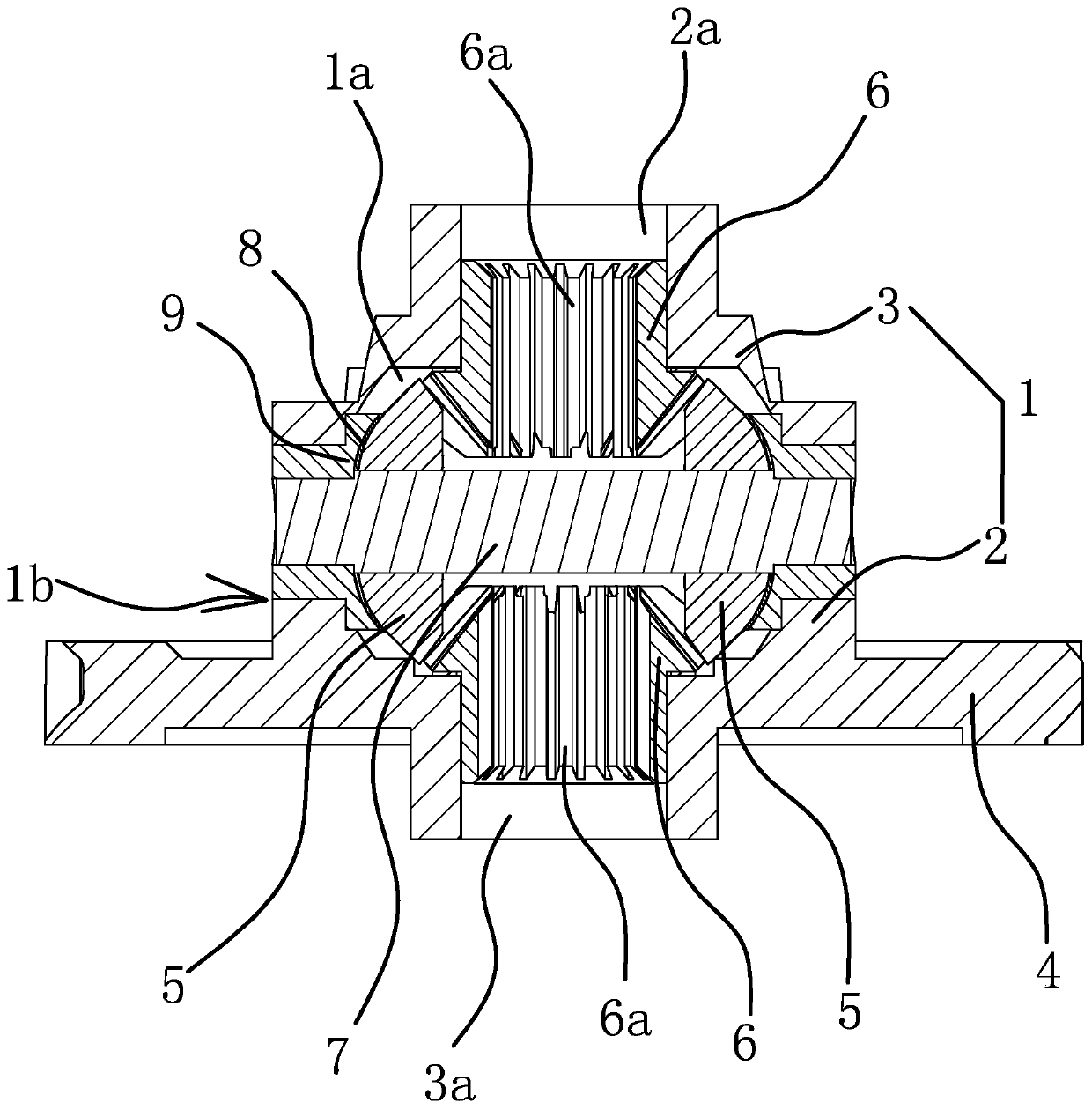

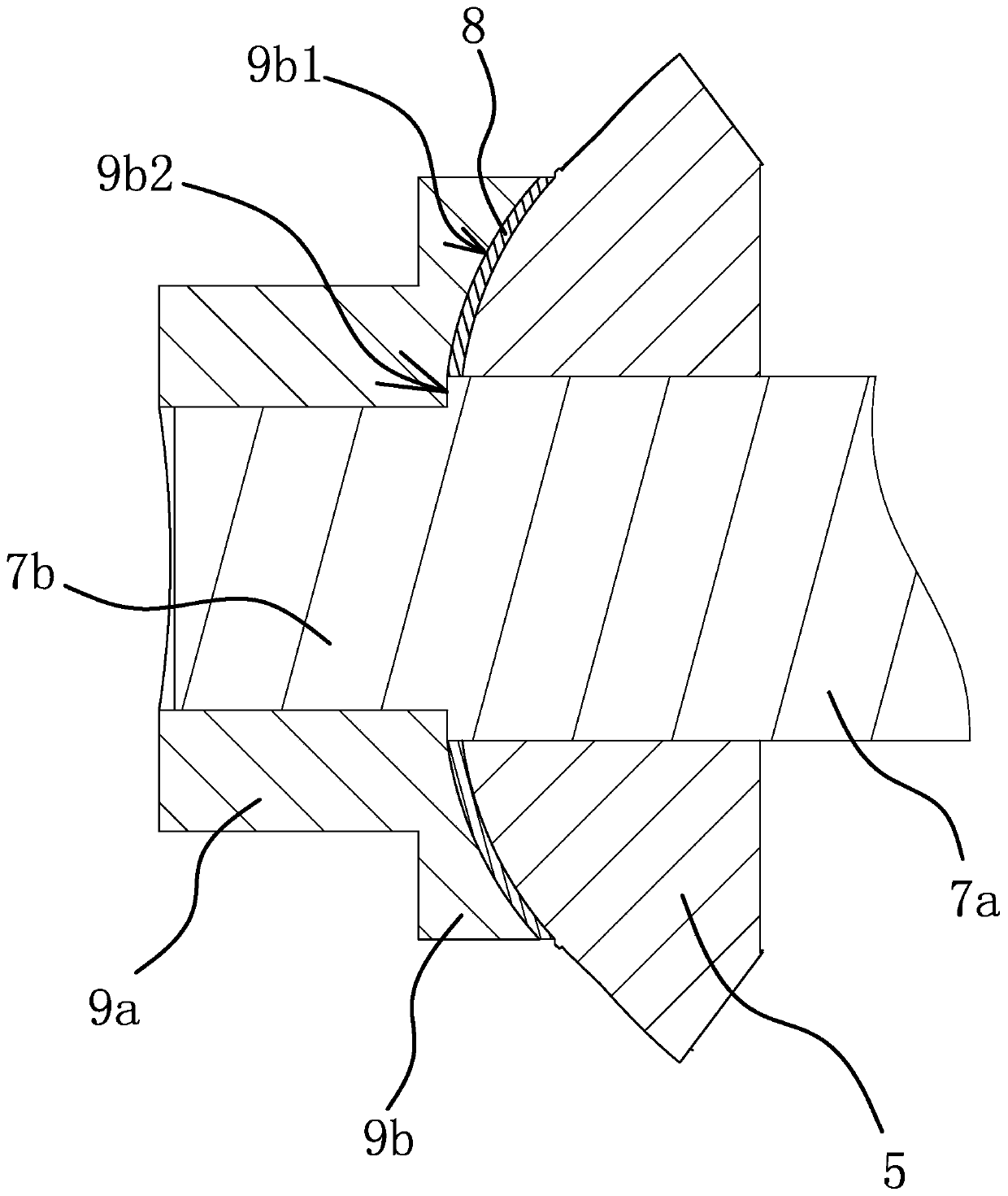

[0039]The differential gear includes a casing 1 , and the casing 1 includes a casing one 2 and a casing two 3 fixed by fasteners 10 . Both the first shell 2 and the second shell 3 are cylindrical with one side open, and the inner cavity of the first shell 2 and the inner cavity of the second shell 3 constitute the installation cavity 1 a of the outer shell 1 . An input gear 4 is fixedly connected to the outer side of the housing one 2, and the two are integrally constructed. Two planetary gears 5 and two side gears 6 are arranged in the installation cavity 1a, and the two planetary gears 5 are meshed with the two side gears 6 respectively. The installation cavity 1a is provided with a positioning shaft 7, and the two planetary gears 5 are respectively sleeved on two ends of the positioning shaft 7, and the side of the housing 1 is provided with a through hole 1b for the two ends of the positioning shaft 7 to pass through. Housing one 2 is provided with connection hole one 2a,...

Embodiment 2

[0047] The structure and principle of this embodiment are basically the same as those of Embodiment 1, the difference is that the shell includes shell one 2 and shell two 3 fixed by fasteners, and shell one 2 and shell two 3 are all in the same shape. The side opening is cylindrical, and the through hole 1b is set on the shell one 2 .

Embodiment 3

[0049] The structure and principle of this embodiment are basically the same as those of the first embodiment, except that the other side of the gasket 8 is a plane, and the mating surface 9b1 is a plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com