High-precision heavy-load thick roller shaft system for speed reducer

A roller shaft, high-precision technology, applied in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve problems such as insufficient torsion resistance, poor impact resistance, and short service life of the whole machine, achieving Increase the load and impact resistance, improve the axial and radial stiffness, and improve the effect of high torque resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

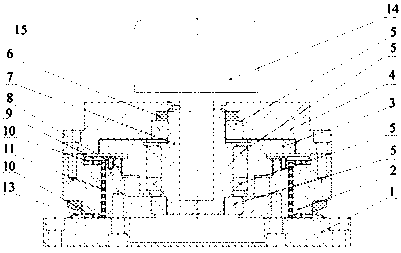

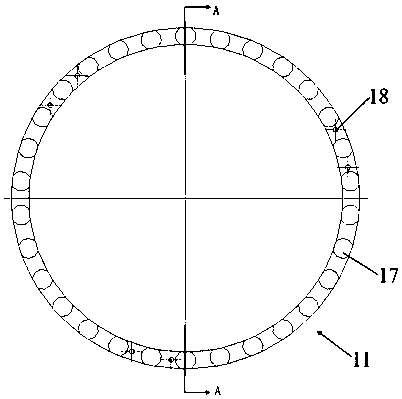

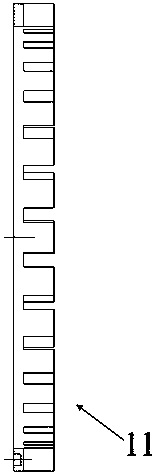

[0034] The following is a detailed description of the high-precision heavy-duty dense roller shafting for the reducer of the present invention in conjunction with the drawings and embodiments of the specification:

[0035] Such as Figure 1~5 As shown, a high-precision heavy-duty dense roller shaft system for a reducer includes a motor 14, and its motor shaft 15 is assembled in a deep hole in the center of the input shaft 7, and the input shaft 7 is equipped with a stepped wheel 3 outside, and both A bearing 5 is arranged between them; the step wheel 3 is externally assembled with an output shaft 8, and a bearing 5 is arranged between the output shaft 8 and the input shaft 7; the output shaft 8 is externally assembled with a body 2; the body 2 and the top of the step wheel 3 are assembled with an input end cover 4 Between the input end cover 4 and the input shaft 7, there are bearings 5 and inner sleeves 6 in order from bottom to top; the input end cover 4 and the body 2 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com