Welding device for engineering machine parts

A welding device and engineering machinery technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as economic loss, easy loss, and impact on work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

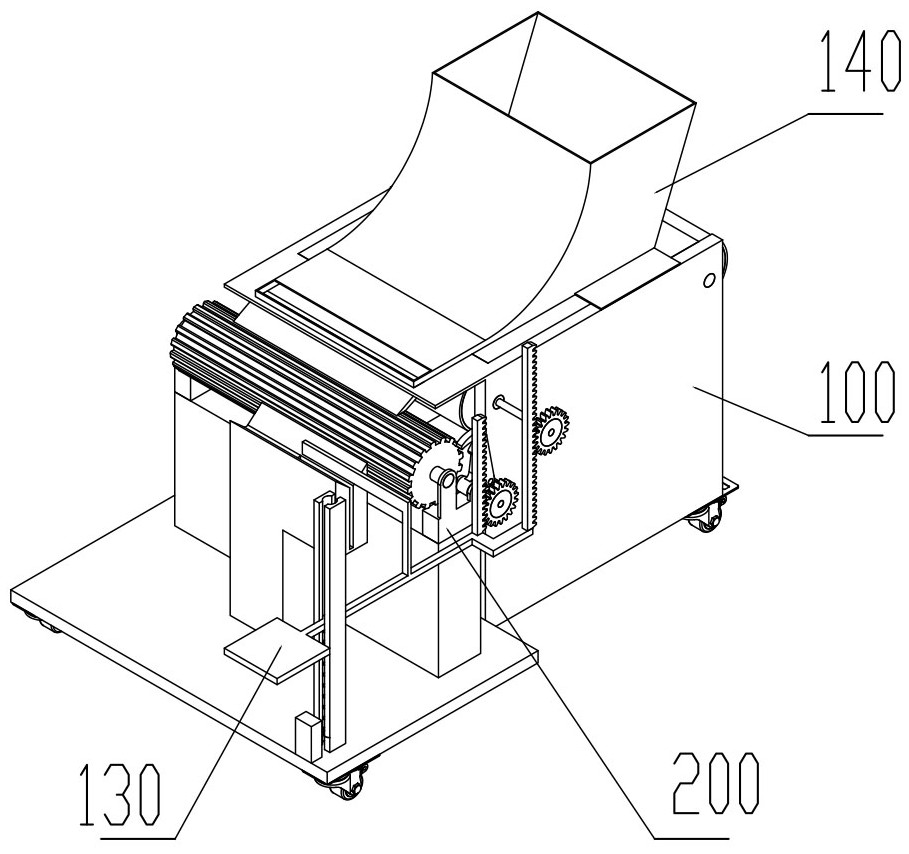

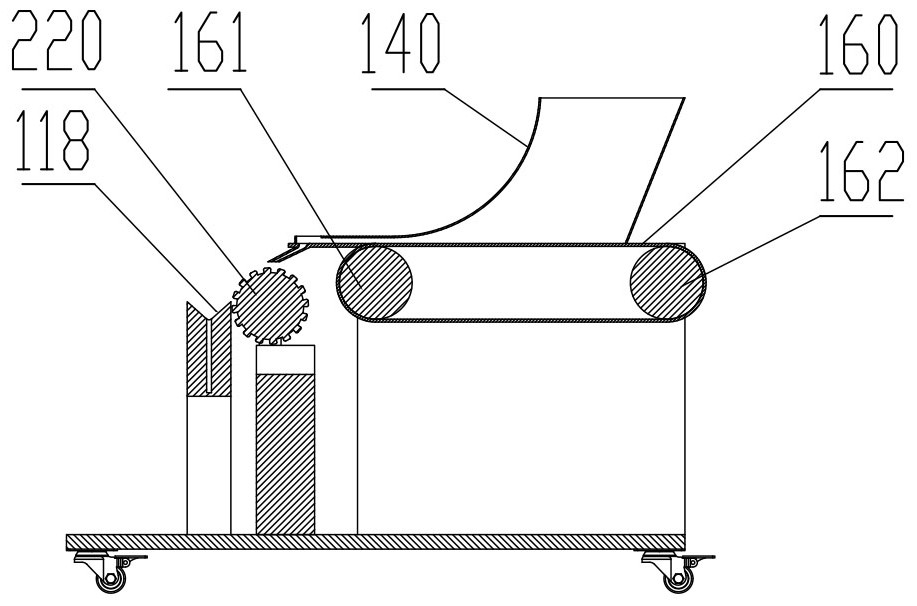

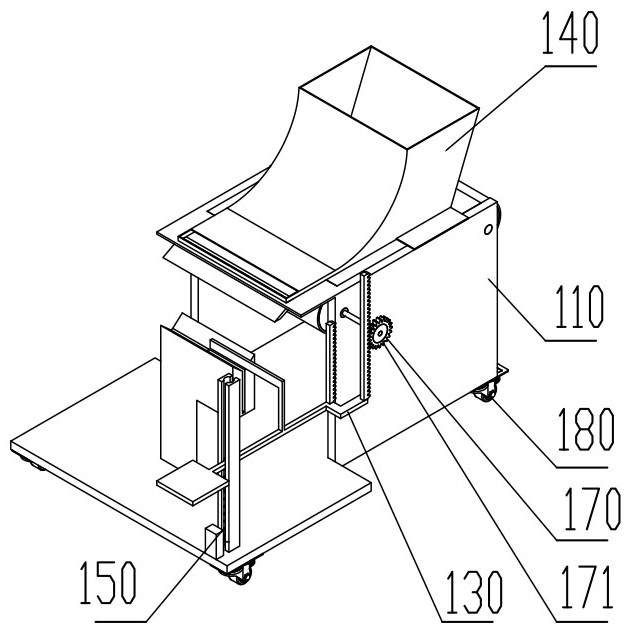

[0022] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

[0023] A welding device for construction machinery parts, including a body device 100, a material shifting device 200, the body device 100 includes a frame 110, a pedal 130, a hopper 140, a spring 150, a belt 160, a front roller 161, a rear roller 162, a No. Gear 170, No. 1 one-way bearing 171, material shifting device 200 includes material shifting rack 210, material shifting roller 220, cam 230, roller 240, pawl frame 250, pawl 260, No. 2 gear 270, No. 2 one-way bearing 271, the material shifting device 200 is fixedly connected to the front of the frame 110; the rear side of the frame 110 has a left-right symmetrical vertical plate 111, and the rear side of the vertical plate 111 has a rear roller hole 112, and the rear roller hole 112 runs through two vertical Plate 111, the front side of the rear roller hole 112 has a front roller hole 113, the front r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com