An automatic fault diagnosis method for underground coalbed methane extraction pipelines in coal mines

An automatic diagnosis and extraction pipe technology, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems that the comprehensiveness and accuracy of the extraction pipeline fault diagnosis need to be further studied, and achieve accurate diagnosis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

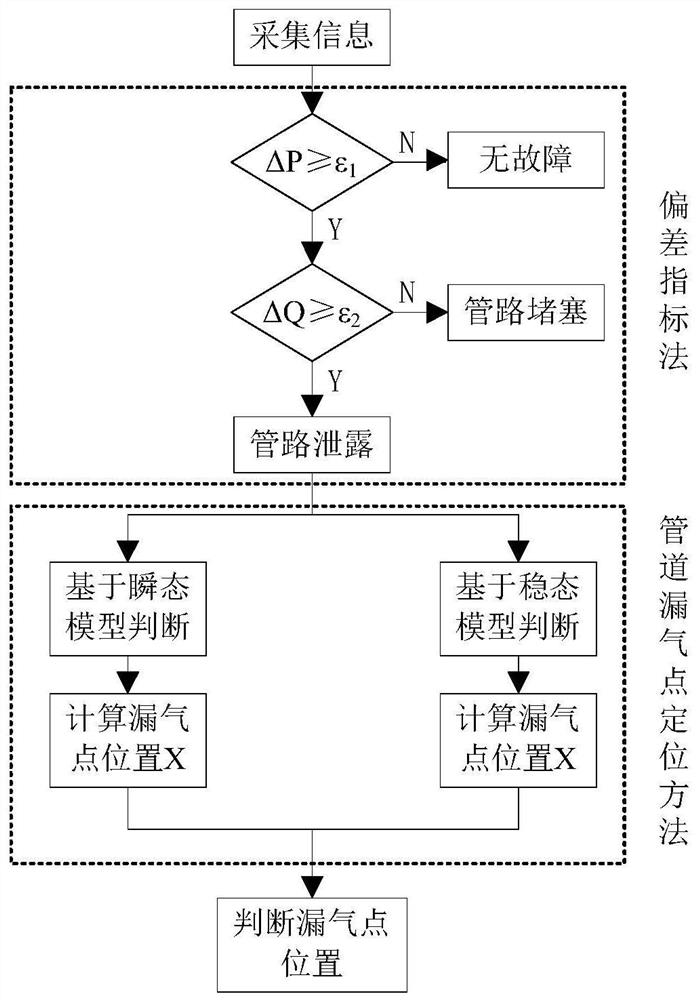

[0041] Such as figure 1 As shown, the present invention carries out automatic diagnosis of coalbed methane extraction pipeline failure in coal mine, comprising the following steps:

[0042] Step 1, collect the drainage negative pressure and mixed flow values of each measuring point in the drainage pipeline, number them from near to far according to the distance between the measuring points and the pumping station, and record the drainage negative pressure and mixed flow of the i-th measuring point Values are P i , Q i ;

[0043] Step 2: Use the deviation index method to analyze whether there is a fault between the i-th measuring point and the i+1-th measuring point of the drainage pipeline, and determine the type of fault. If the fault type is pipeline leakage, perform step 3, otherwise directly execute Step 4;

[0044] Step 3, using the pipeline air leakage point positioning method to determine the location of the air leakage point between the i-th measuring point and...

Embodiment 2

[0060] Such as figure 1 As shown, it is basically the same as Example 1. The different parts are mainly that the method for locating the pipeline air leakage point in step 3 in Embodiment 1 adopts the method for locating the pipeline air leakage point based on the steady-state model.

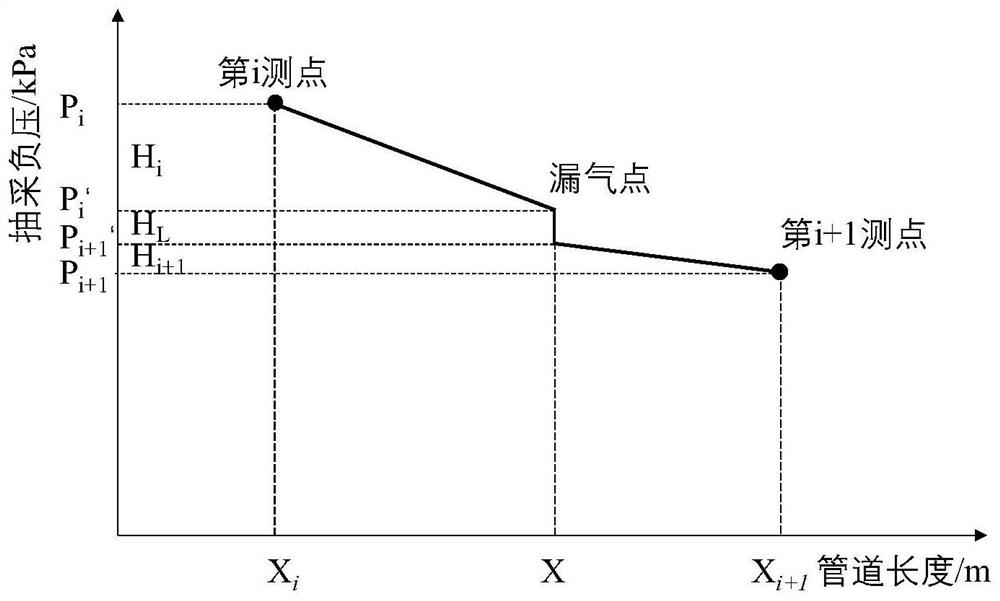

[0061] Such as image 3 As shown, the pipeline air leakage point location method in the step 3 adopts the pipeline air leakage point location method based on the steady-state model, and the calculation process of the pipeline air leakage point location method based on the steady-state model is as follows:

[0062] a. Collect the extraction negative pressure value of the i-th measuring point and the i+1-th measuring point at a certain moment;

[0063] b. According to the drainage parameters of the i-th measuring point and the drainage parameters of the i+1-th measuring point, use the following equation to calculate the pipeline length X from the air leakage point to the drainage pump

[0064] ...

Embodiment 3

[0072] Such as figure 1 As shown, it is basically the same as Example 1. The different parts are mainly the method for locating the pipeline air leakage point in step 3 in Embodiment 1. The method for locating the pipeline air leakage point based on the combination of the transient model and the steady state model is adopted.

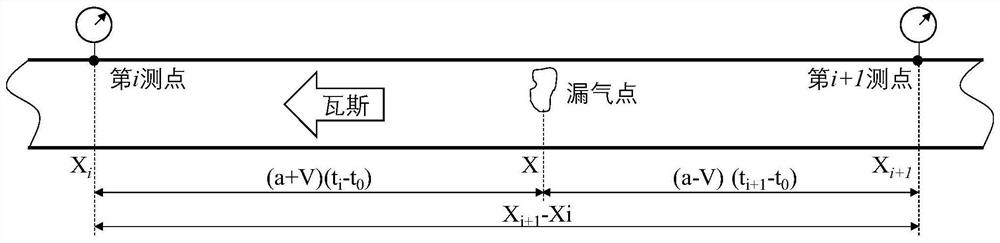

[0073] Such as figure 2 As shown, the calculation process of the pipeline air leakage point location method based on the transient model is as follows:

[0074] a. Collect the extraction negative pressure values of the i-th measuring point and the i+1-th measuring point at different times;

[0075] b. Graphing and analyzing the time-course curves of negative pressure extraction at the i-th measuring point and the i+1-th measuring point to find out the sudden change point of the negative pressure. t i , t i+1 ;

[0076] c. Use the following calculation formula to calculate the location of the leak point X s

[0077]

[0078] Such as image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com