LED ceiling lamp with long service life

A LED chandelier with a long service life technology, which is applied in semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, lighting devices, etc., and can solve problems such as short service life of lamps, component damage, and cooling fins loaded on chandelier, and achieve Improve heat dissipation efficiency, speed up operation, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

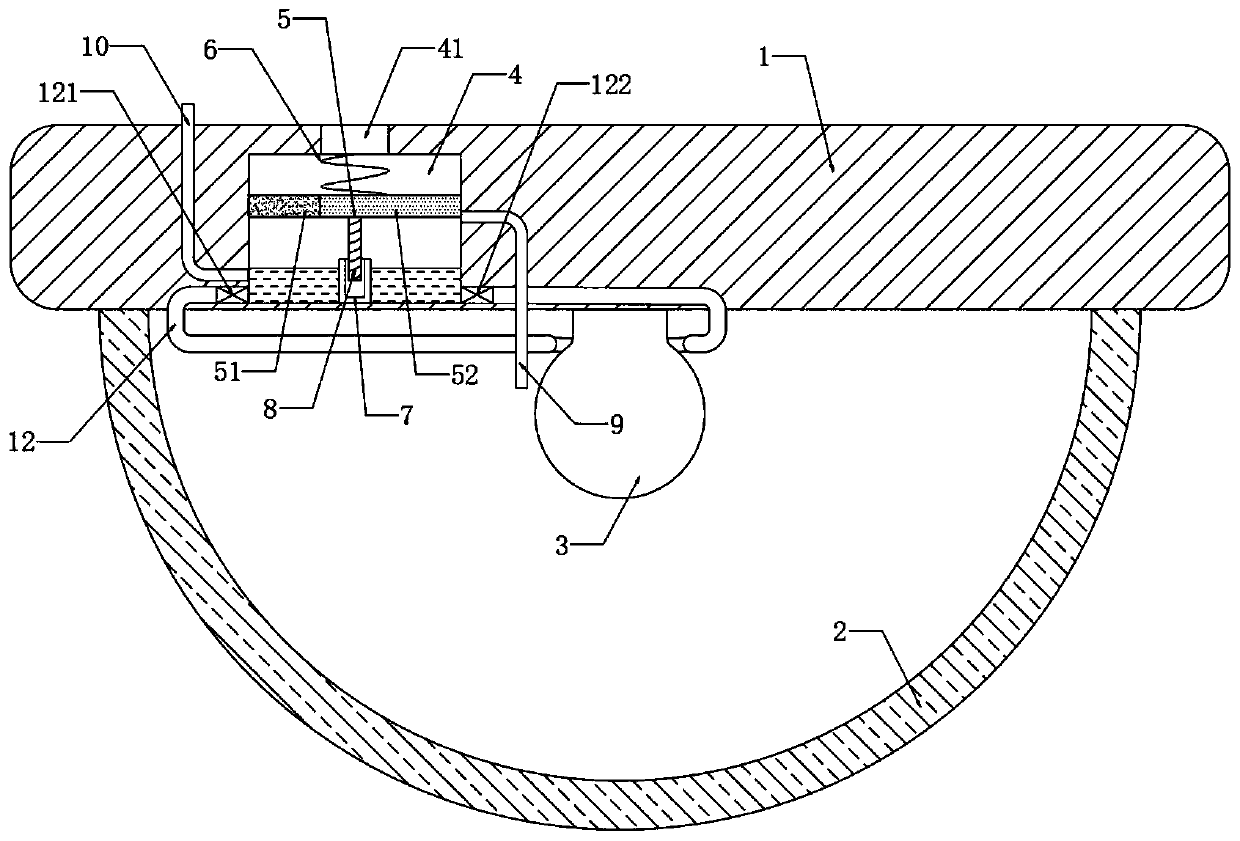

[0019] refer to figure 1 , an LED pendant lamp with long service life, comprising a mounting plate 1, a lamp housing 2 is installed at the lower end of the mounting plate 1, and an LED lamp body 3 is installed in the lamp housing 2.

[0020] The side wall of the mounting plate 1 is provided with a liquid storage tank 4, and a sliding plug 5 is sealed and slidably connected in the liquid storage tank 4. The liquid storage tank 4 is filled with cooling liquid, and the lamp housing 2 is embedded with a There is a condensing pipe 12, and the liquid inlet end and the liquid outlet end of the condensing pipe 12 are connected with the liquid storage tank 4, and the liquid inlet end and the liquid outlet end of the condensing pipe 12 are respectively installed with a first one-way The valve 121 and the second one-way valve 122, the liquid storage tank 4 is equipped with a driving device for driving the sliding plug 5 to move up and down.

[0021] It should be noted that the first one...

Embodiment 2

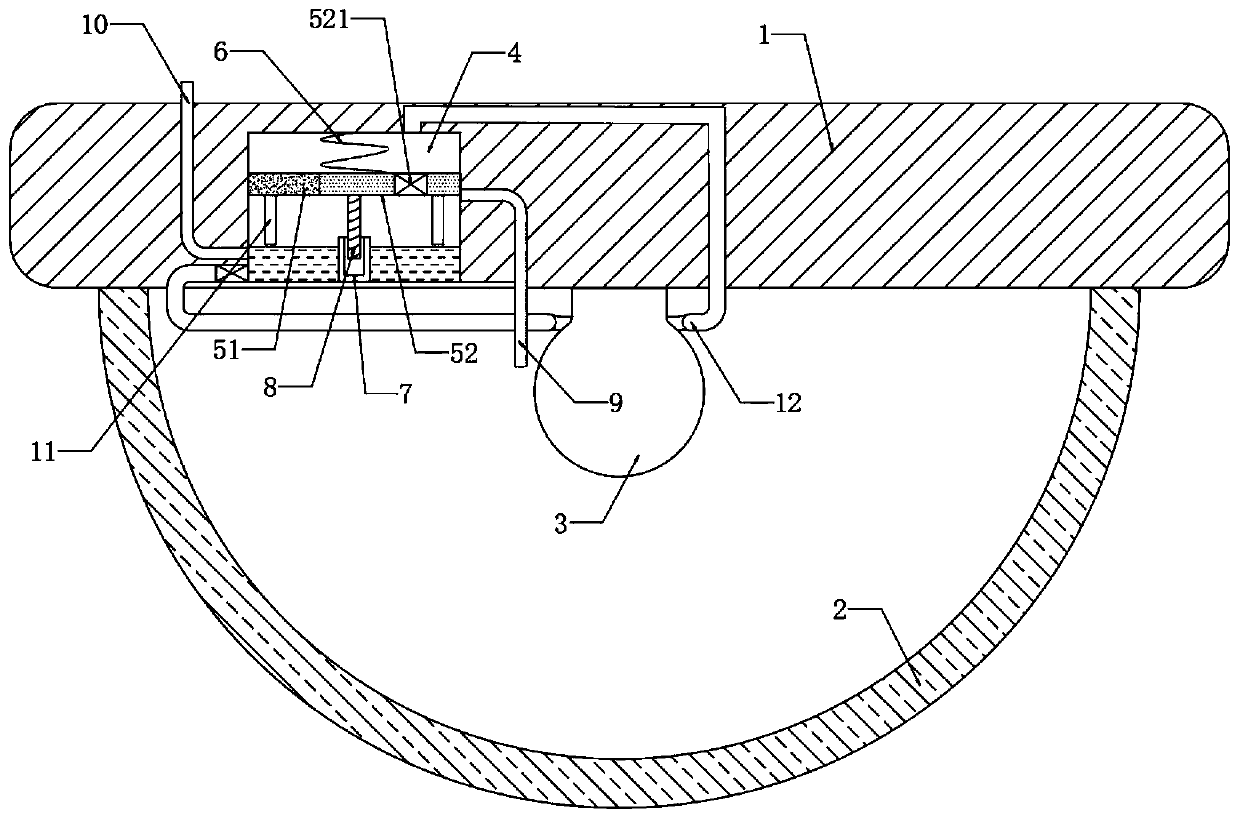

[0031] refer to figure 2 , different from Embodiment 1, the lower end of the sliding plug 5 is fixedly connected with a spoiler 11, the liquid outlet end of the condensation pipe 12 is fixedly connected with the inner top of the liquid storage tank 4, and the side wall of the heat conducting plug 52 is provided with a one-way Liquid outlet hole 521.

[0032] It should be noted that the one-way liquid outlet hole 521 only allows the cooling liquid to flow from above the slide plug 5 to below the slide plug 5 . Specifically, in the manufacturing process, the one-way liquid outlet function can be realized only by installing a one-way valve in the liquid outlet hole.

[0033] In this embodiment, during the rotation process of the sliding plug 5 under the action of the threaded sleeve 7 and the threaded rod 8, it will drive the spoiler 11 below to rotate, which can stir the cooling liquid in the liquid storage tank 4 and speed up the cooling process. The speed of heat loss in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com