Novel safe alcohol lamp and preparation method

An alcohol lamp and safe technology, applied in the field of alcohol lamps, can solve problems such as safety accidents and alcohol spills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016] Example 1

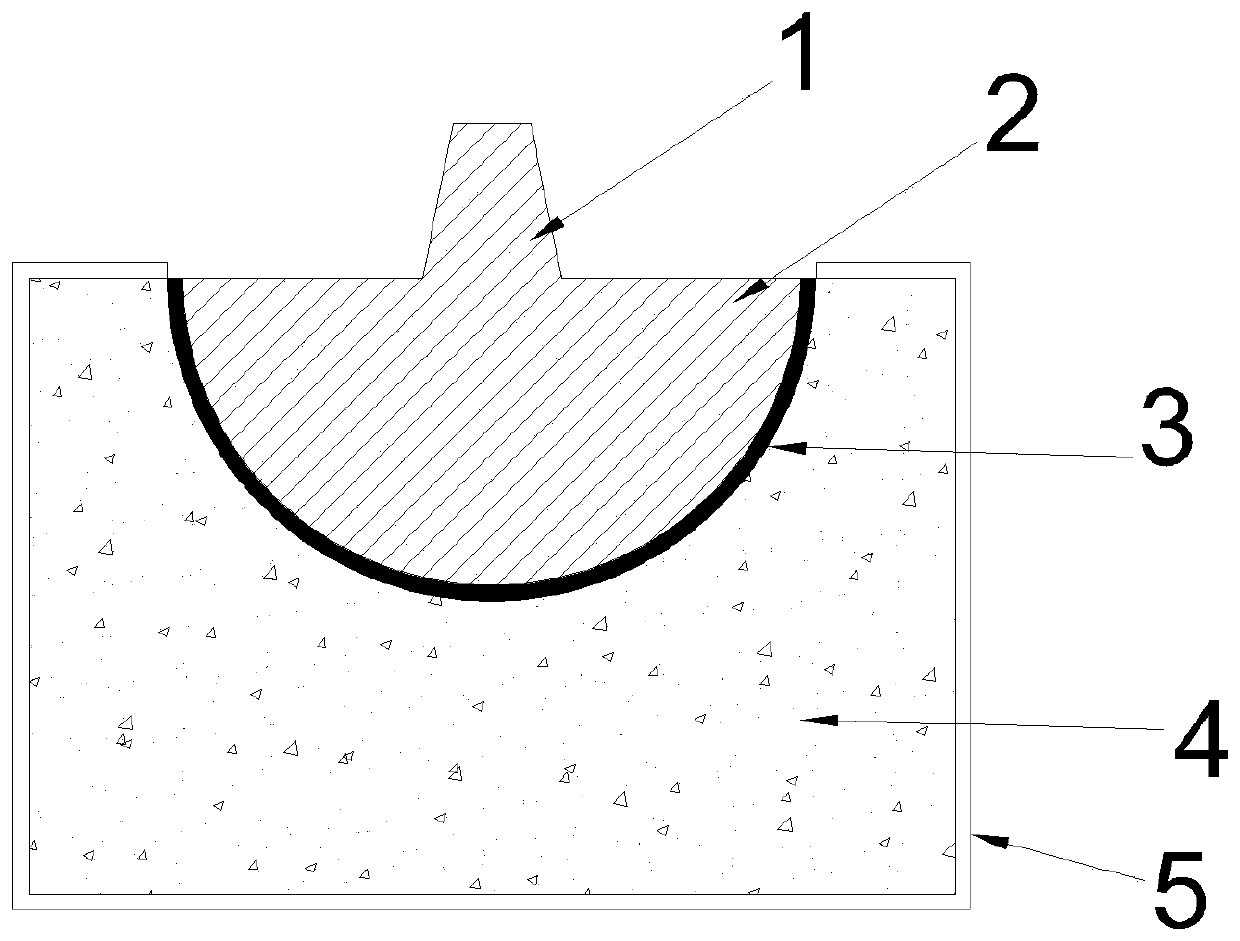

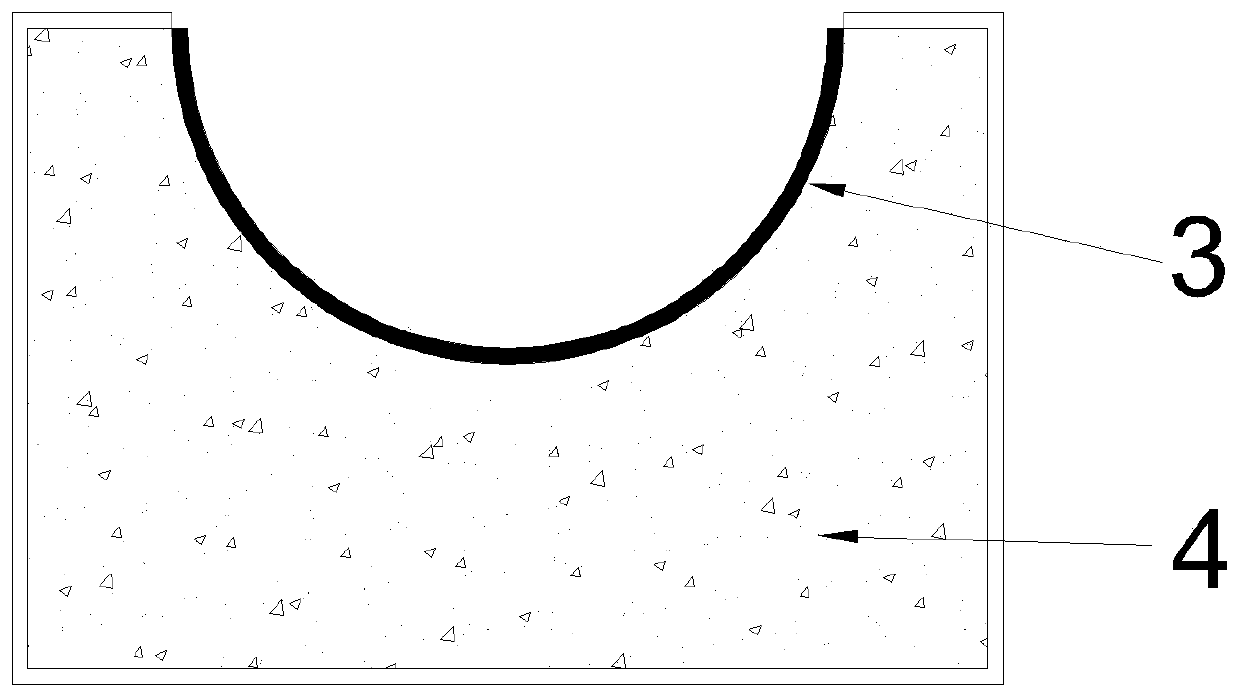

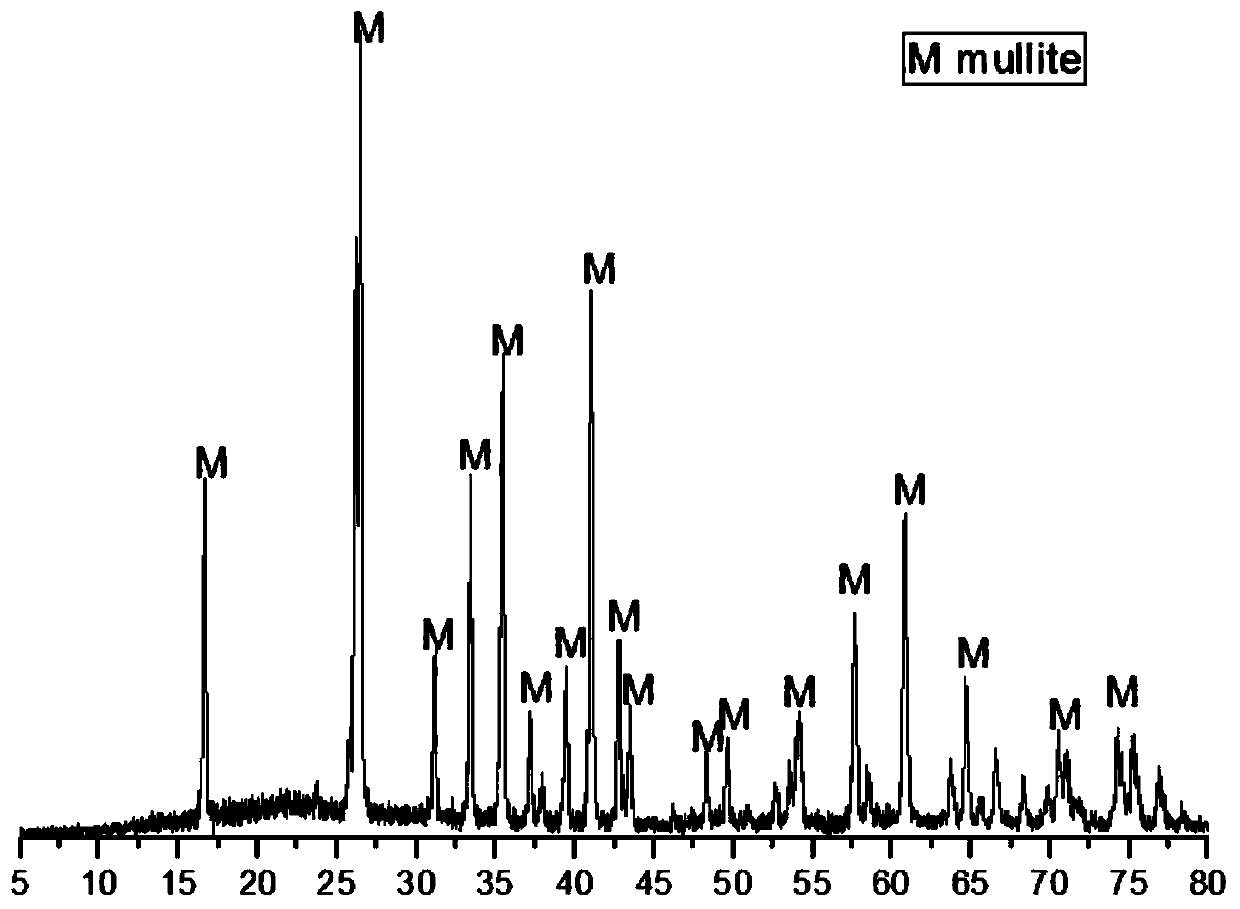

[0017] Step 1: Integrated preparation of wick 1 and cup body 2. After mixing 28g of diatomaceous earth and 72g of alumina, take 95g of mixed powder, add 5g of MoSi2 powder, ball mill the mixed powder with a ball mill for 12 hours, and add the powder after ball milling Mix 10g of starch, add water to prepare a slurry, with a solid content of 30wt%, pour the slurry into a mold of the corresponding shape, and then place it in an oven at 150°C for 3 hours, and place the dried sample in a covered ceramic crucible In the process, a porous ceramic with mullite whisker structure is obtained after debinding and sintering in a resistance furnace. The specific heating program is to heat up at 1°C / min to 300°C for 1 hour, then continue to heat up at 1°C / min to 600°C for 2 hours to debinding, continue to heat up at 5°C / min to 1300°C for 2 hours, and cool down with the furnace to get the appearance Cylindrical porous mullite ceramic with needle-like structure, with a porosi...

Example Embodiment

[0020] Example 2

[0021] Step 1: Integrated preparation of wick 1 and cup body 2. After mixing 28g of diatomaceous earth and 72g of alumina, take 97g of mixed powder, then add 3g of MoSi2 powder, and mill the mixed powder with a ball mill for 15 hours. The powder after ball milling Add 15g starch and mix well, add water to prepare a slurry with a solid content of 40wt%. Pour the slurry into a cylindrical mold with a diameter of 2cm and a depth of 5cm, and place it in an oven at 150℃ and bake for 3 hours. In a ceramic crucible with a lid, a porous ceramic with a mullite whisker structure is obtained after debinding and sintering in a resistance furnace. The specific heating program is to heat up at 2°C / min to 300°C for 1 hour, then continue to heat up at 1°C / min to 600°C for 2 hours to debinding, continue to heat up at 5°C / min to 1400°C for 2 hours, and cool down with the furnace. Porous mullite ceramics with a shape structure, with a porosity of 78% and a pore size of 2um.

[00...

Example Embodiment

[0024] Example 3

[0025] Step 1: Integrated preparation of wick 1 and cup body 2. After mixing 28g of diatomaceous earth and 72g of alumina, take 99g of mixed powder, then add 1g of MoSi2 powder, and mill the mixed powder with a ball mill for 18 hours. The powder after ball milling Add 10wt% starch and mix well, add water to prepare a slurry with a solid content of 60wt%. Pour the slurry into a cylindrical mold with a diameter of 2cm and a depth of 5cm. Place it in an oven and bake at 150℃ for 3 hours. Place the dried sample The porous ceramics with mullite whisker structure are obtained after debinding and sintering in a resistance furnace in a covered ceramic crucible. The specific heating program is to heat up at 3°C / min to 300°C for 1 hour, then continue to heat up at 1°C / min to 600°C for 2 hours to debinding, continue to heat up at 5°C / min to 1600°C for 2 hours, and cool down with the furnace to get the appearance Cylindrical porous mullite ceramics with needle-like struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap