Preparation method and application of n,s co-doped carbon/tin disulfide composite material

A technology of tin disulfide and composites, which is applied in the field of preparation of carbon/tin disulfide composite materials, can solve the problems of energy consumption, time-consuming, complex synthesis process, etc., and achieve high potassium storage capacity, excellent cycle stability, and high purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

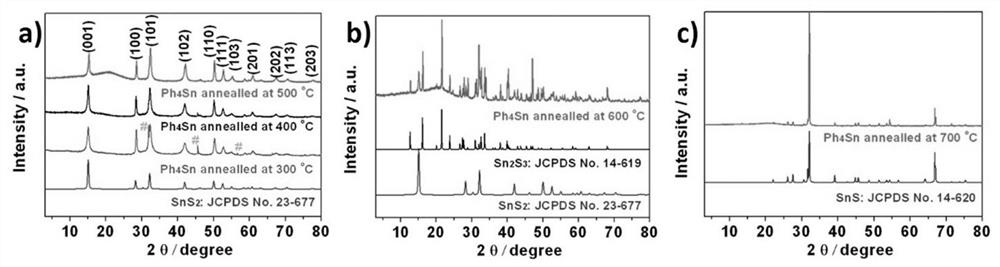

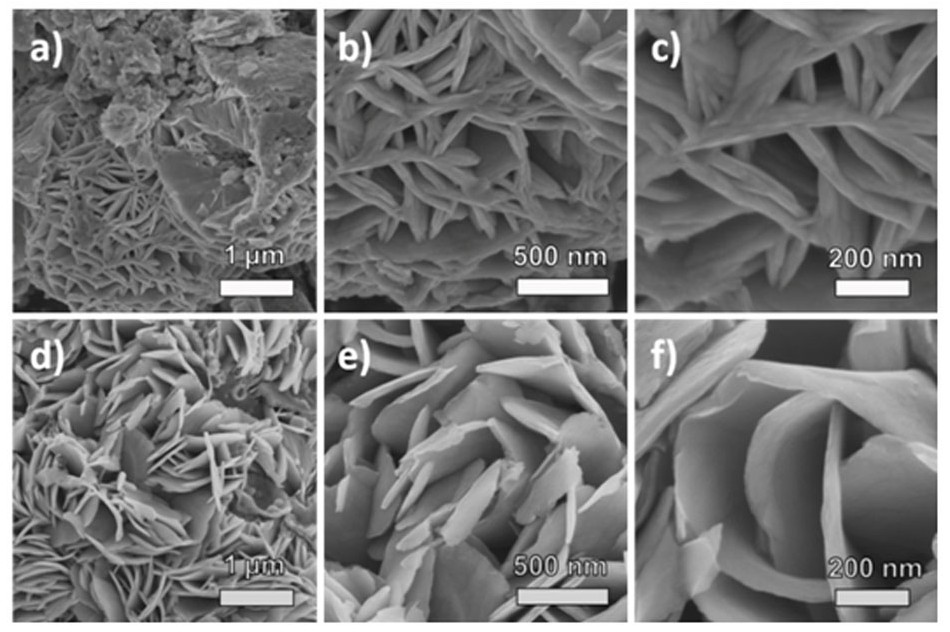

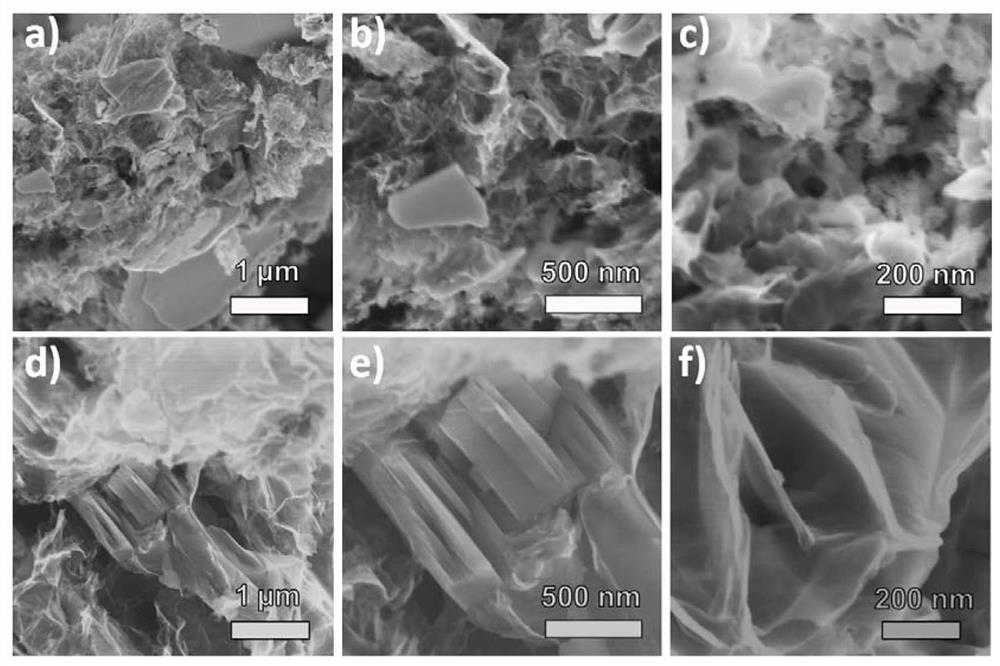

[0025] Weigh 0.5g tetraphenyl tin and place it in porcelain boat A, weigh 1.0g thiourea and place it in porcelain boat B, place porcelain boat A and porcelain boat B in a tube furnace filled with argon, and seal it; The temperature of the tube furnace is raised to 500 °C at 5 °C / min, and it is kept for 1~3 hours. When the temperature of the tube furnace is naturally cooled to 100~200 °C, argon gas is introduced, and the reaction tail gas is treated with 1mol / L sodium hydroxide solution and water successively. After discharge, the temperature was naturally lowered to room temperature, and the target product sample was obtained.

Embodiment 2

[0027] Weigh 0.5g tetraphenyl tin and place it in porcelain boat A, weigh 1.5g thiourea and place it in porcelain boat B, place porcelain boat A and porcelain boat B in a tube furnace filled with argon, and seal it; The temperature of the tube furnace is raised to 500 °C at 5 °C / min, and it is kept for 1~3 hours. When the temperature of the tube furnace is naturally cooled to 100~200 °C, argon gas is introduced, and the reaction tail gas is treated with 1mol / L sodium hydroxide solution and water successively. After discharge, the temperature was naturally lowered to room temperature, and the target product sample was obtained.

Embodiment 3

[0029] Weigh 0.5g tetraphenyl tin and place it in porcelain boat A, weigh 2.0g thiourea and place it in porcelain boat B, place porcelain boat A and porcelain boat B in a tube furnace filled with argon, and seal it; The temperature of the tube furnace is raised to 500 °C at 5 °C / min, and it is kept for 1~3 hours. When the temperature of the tube furnace is naturally cooled to 100~200 °C, argon gas is introduced, and the reaction tail gas is treated with 1mol / L sodium hydroxide solution and water successively. After discharge, the temperature was naturally lowered to room temperature, and the target product sample was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com