Iron art product colored drawing varnishing mechanism

A technology for iron art and color painting, applied in the direction of spraying device, etc., can solve the problems of inconvenient painting on the inclined surface of iron art, inconvenient adjustment of the angle of the brush head, etc., and achieve the effect of improving the painting effect, avoiding displacement and increasing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

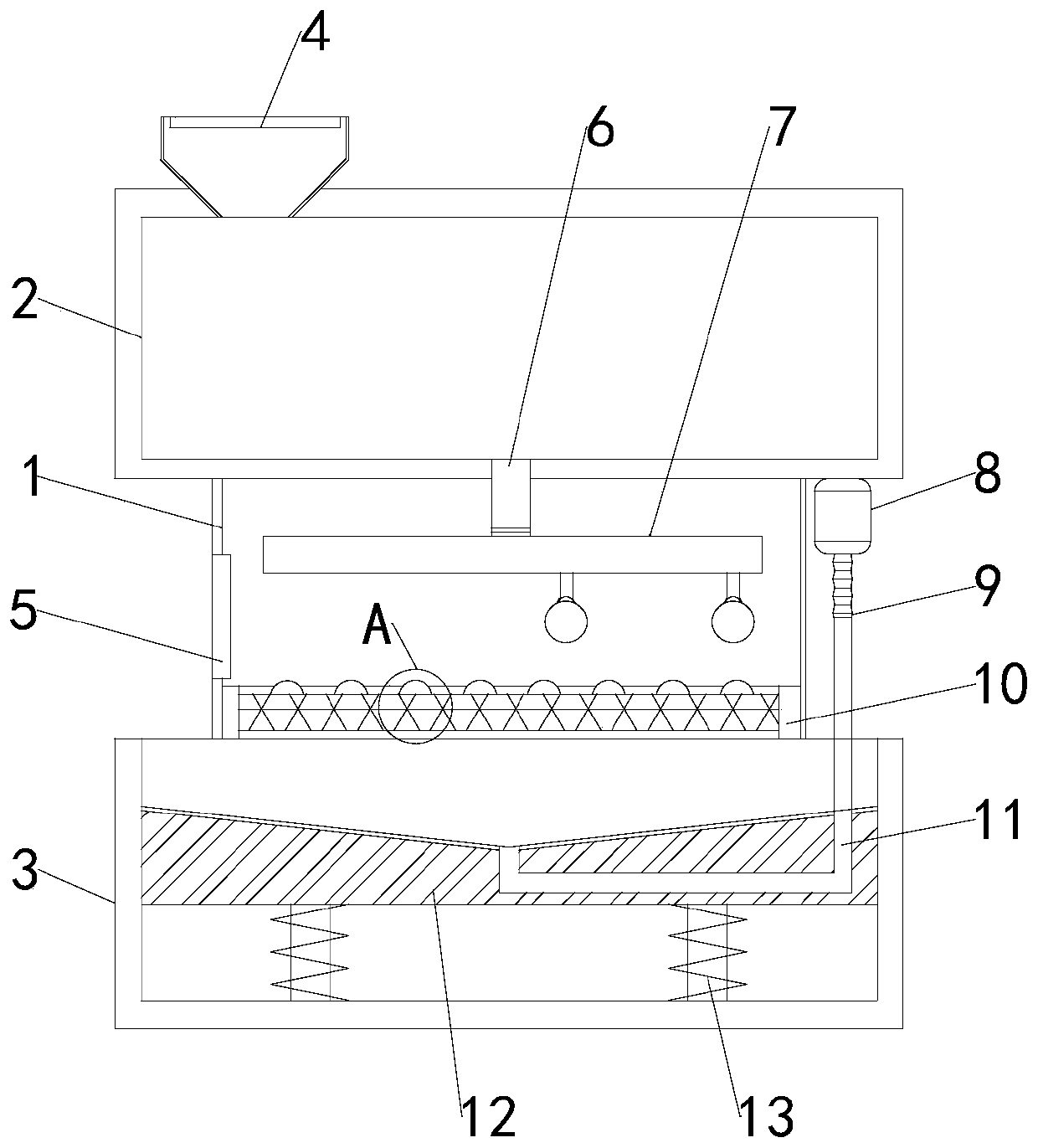

[0024] see Figures 1 to 7 Among them, in the embodiment of the present invention, a kind of painting mechanism for iron art products includes: a painting mechanism 1, a material storage chamber 2, a material collection chamber 3, a slide rail 7 and a filter plate 10, and the inside of the painting mechanism 1 is provided with The painting part, and the upper and lower parts of the painting mechanism 1 are provided with collecting parts, the left end of the painting mechanism 1 is slotted and provided with a port 5, and the upper and lower ends of the painting mechanism 1 are integrally provided with material storage chambers 2 and collection chamber 3.

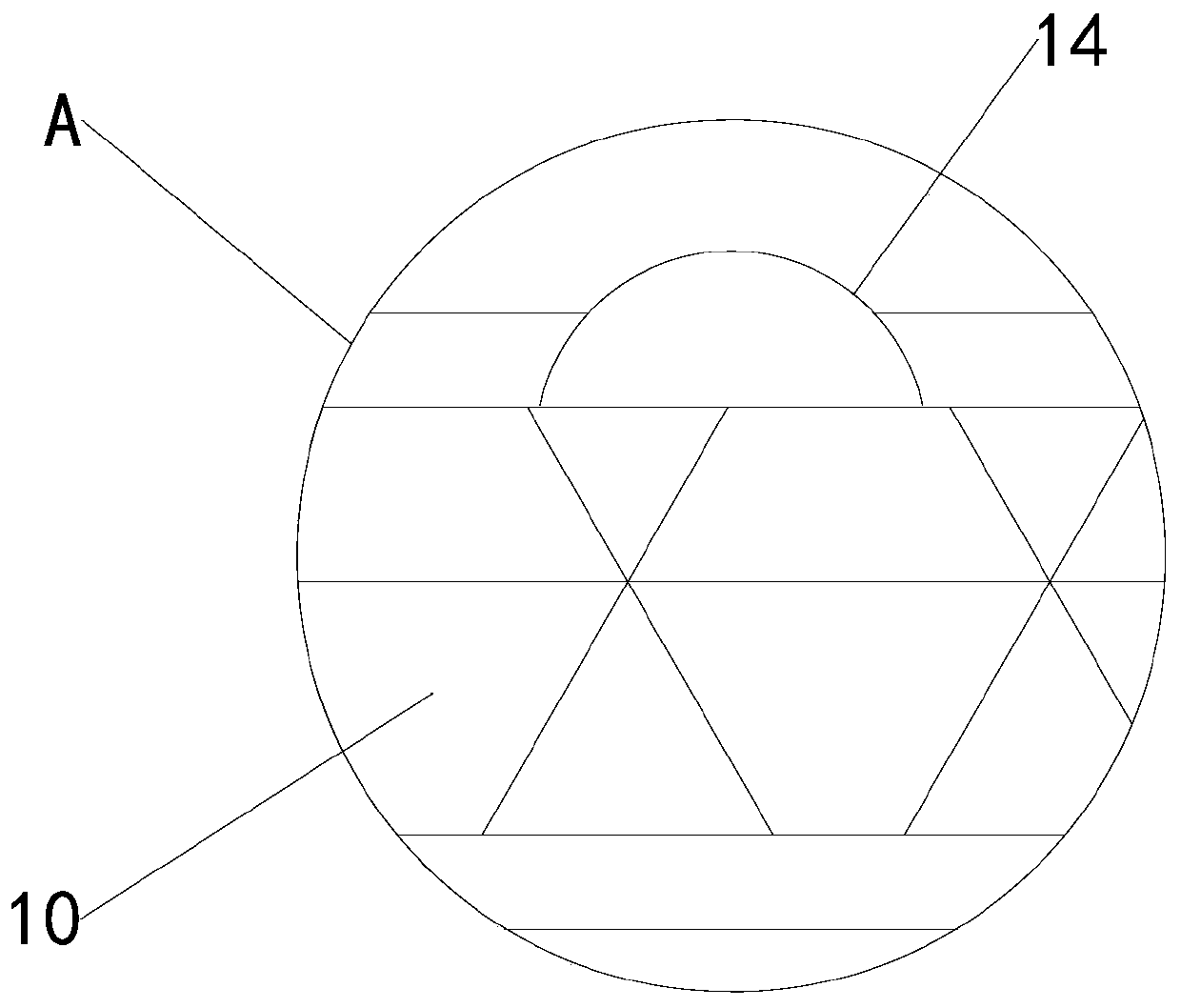

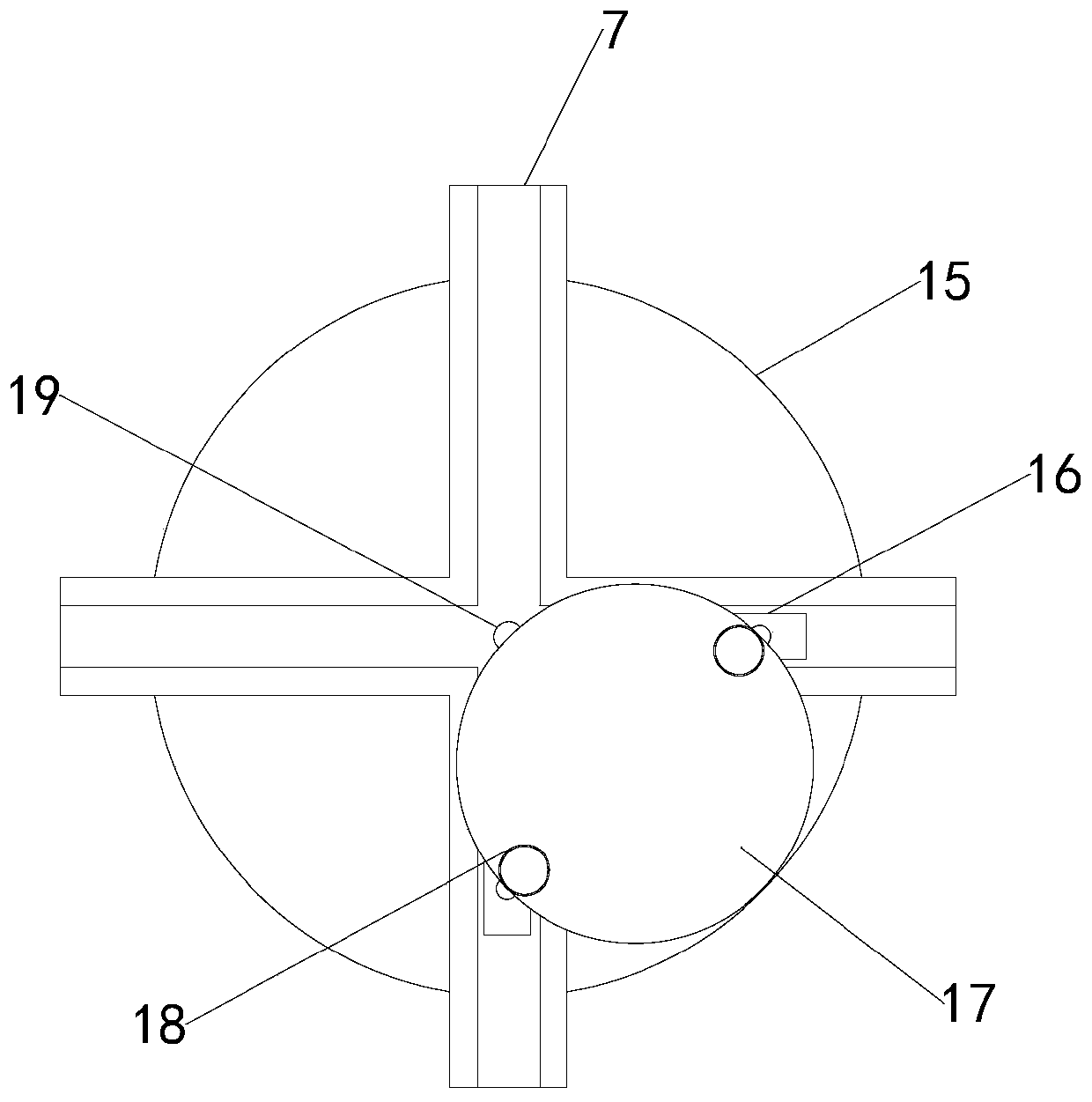

[0025] Preferably, the painting parts include: a slide rail 7 and a filter plate 10, the top of the slide rail 7 is fixedly connected with a connecting column 6, and the top of the connecting column 6 is fixedly connected to the inner top of the painting mechanism 1, and the slide rail 7 is " "Ten" shape, and the disc 15 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com