Automatic blanking assembly line

An automatic cutting and assembly line technology, applied in the field of assembly line, can solve problems such as affecting work efficiency, safety production accidents, and increase in labor costs, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

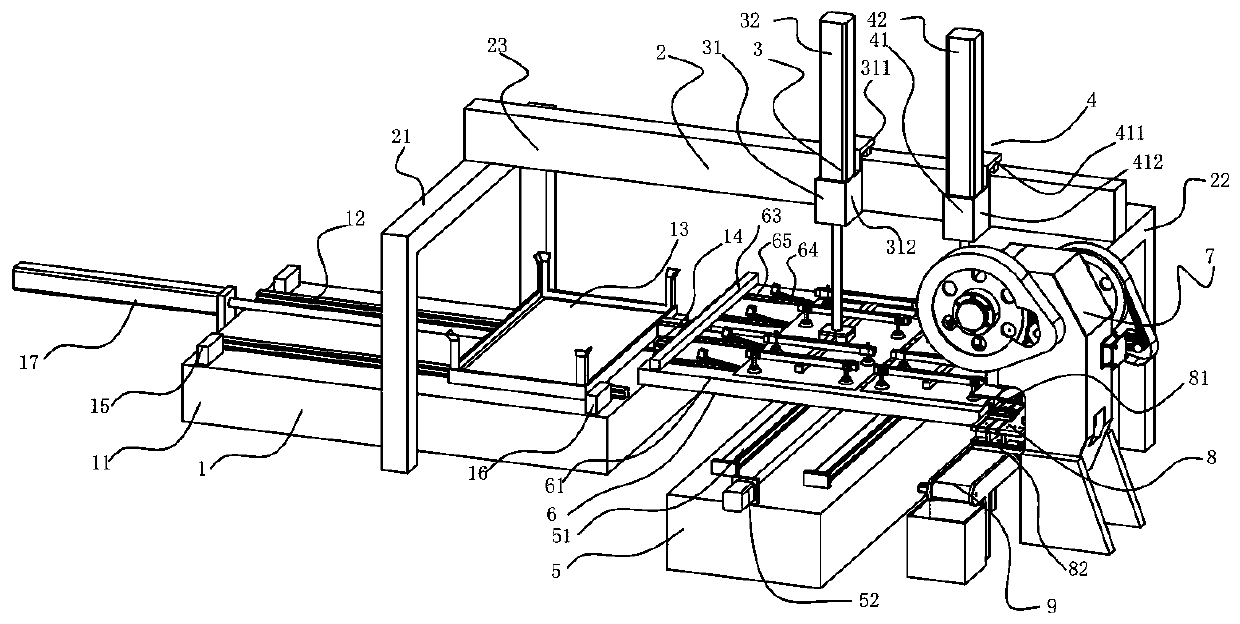

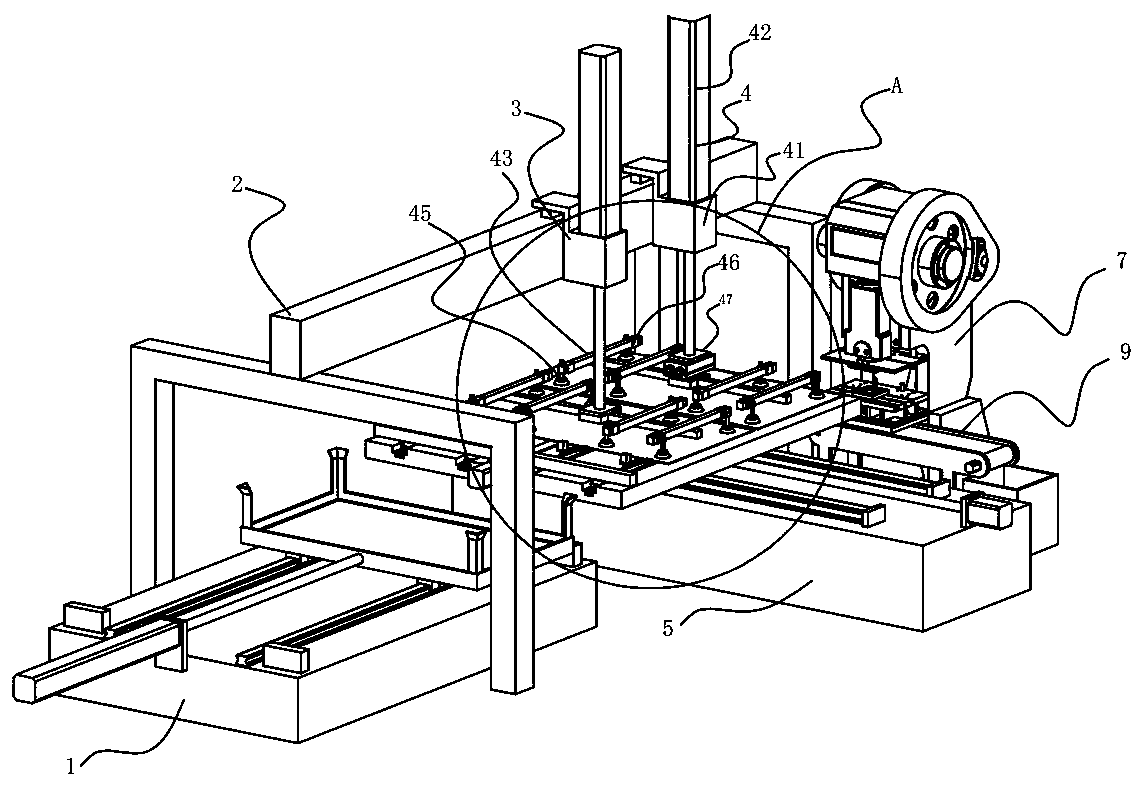

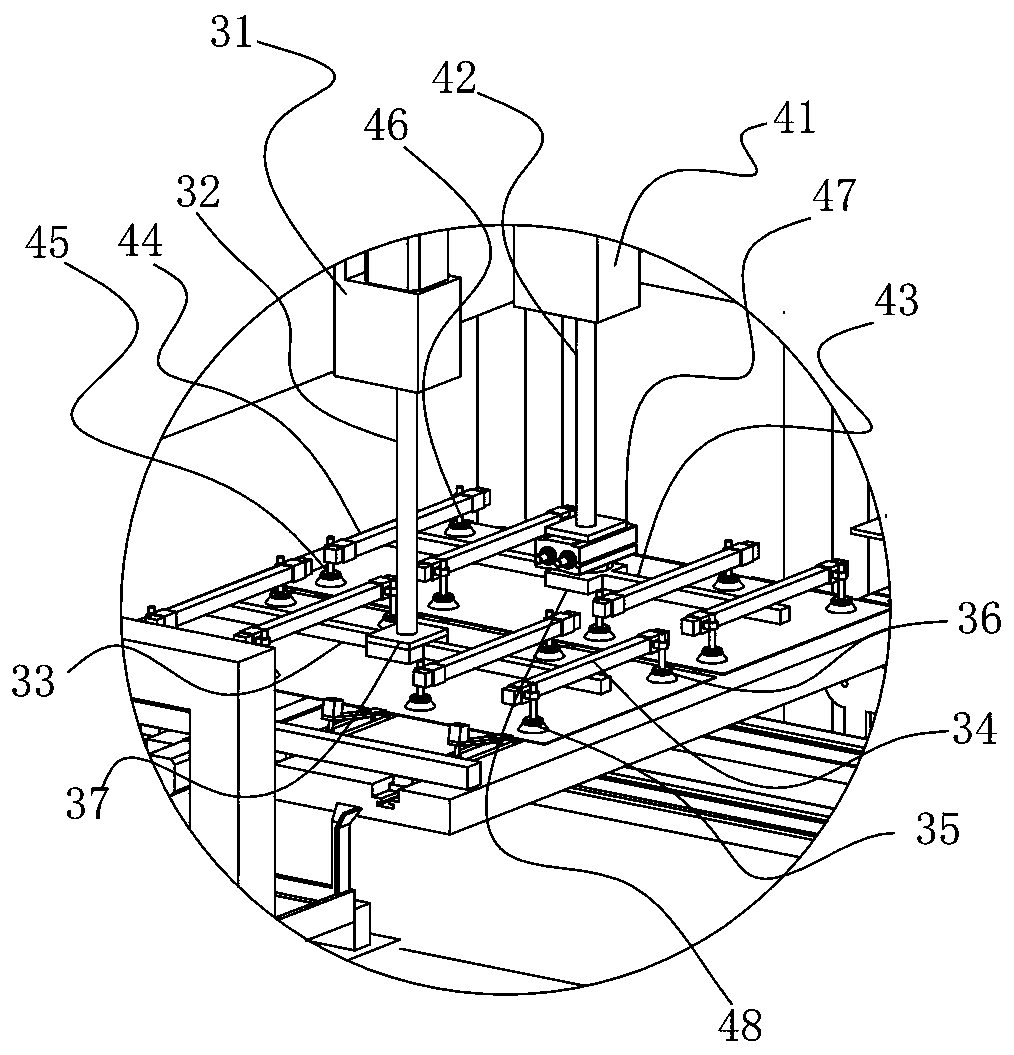

[0039] refer to figure 1 , according to one embodiment of the present invention, the present invention discloses an automatic unloading assembly line, comprising a mobile material placement table assembly 1, the mobile material placement table assembly 1 includes a second support platform 11, which is set on the second The guide rail assembly 12 on the support platform 11, the material placement table 13 arranged on the guide rail assembly 12, and the oil cylinder assembly 17 that controls the movement of the material placement table 13 on the guide rail assembly 12; wherein, the guide rail assembly 12 includes two through bolts The guide rails (not marked in the figure) fixed on both sides of the second support platform 11, the two guide rails (not marked in the figure) are respectively away from the cylinder assembly 17 and parallel to each other, and the bottom of the material placement table 13 is provided with a guide rail assembly 12-phase sliding combination of sliders ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com