A single-pipe water-cooled casting mold based on multi-position accelerated heat dissipation

A casting and welding mold, multi-position technology, applied in the field of single-tube water-cooled casting and welding molds, can solve the problems of mold heat absorption, poor heat dissipation, casting and welding, etc., to improve casting and welding efficiency, reduce mold area, and shorten casting and welding cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

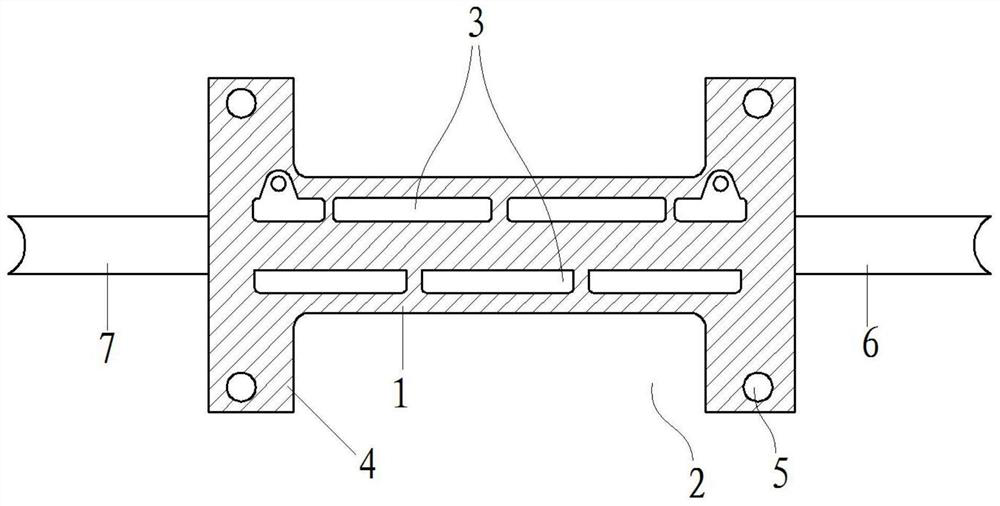

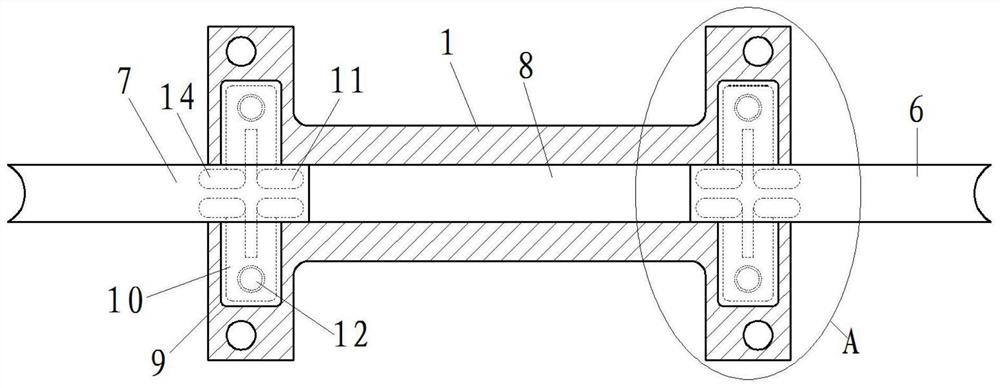

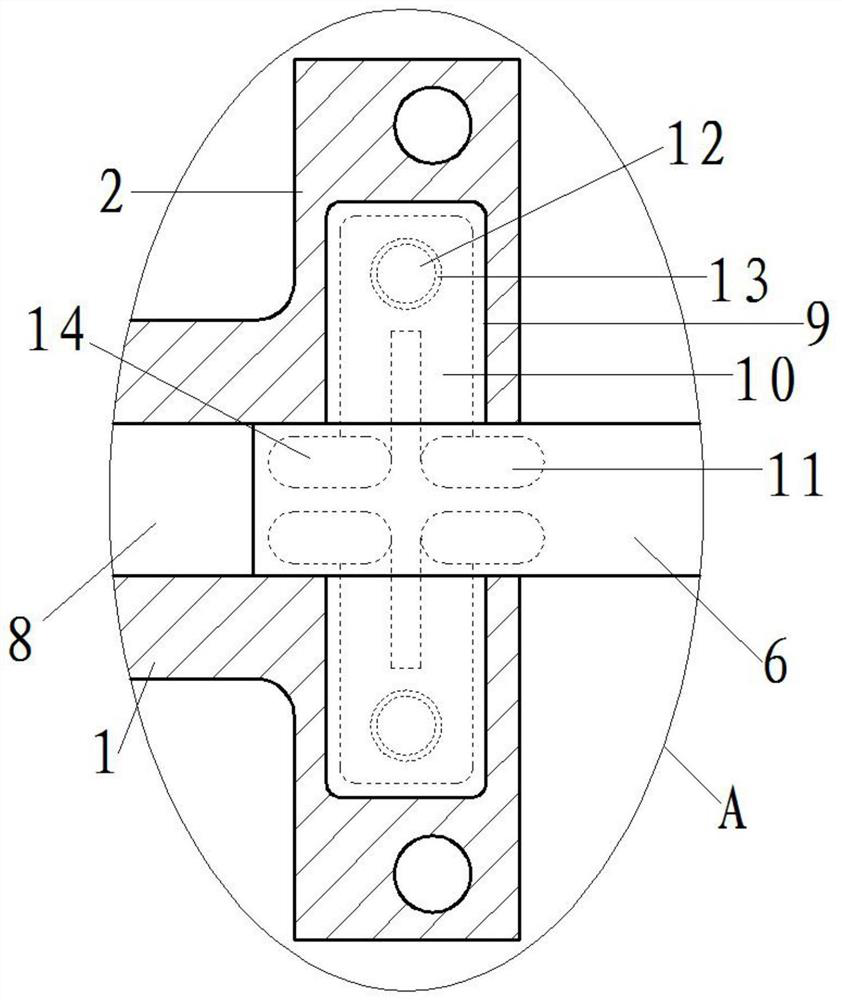

[0025] see figure 1 , figure 2 , image 3 , both sides of the casting and welding mold 1 are provided with side inner grooves 2, and the four corners of the casting and welding mold 1 are corner plates 4 with the same structure, and each corner plate 4 is provided with a corresponding position The corner positioning hole 5 of the casting and welding mold 1 is provided with a casting and welding groove 3 on the upper side panel of the casting and welding mold 1. The bottom of the casting and welding mold 1 is provided with an upwardly convex cooling pipe section 8 by inserting, embedding, etc., and one end of the upwardly convex cooling pipe section 8 It communicates with the water inlet pipe 6, and the other end of the upwardly convex cooling pipe section 8 communicates with the water outlet pipe 7, and the horizontal height of the upwardly convex cooling pipe section 8 is higher than the water inlet pipe 6 and the water outlet pipe 7.

[0026] The bottom of the corner plat...

Embodiment 2

[0028] Please refer to, the four corner positioning holes 5 of the casting and welding mold 1 are consistent with the mold structure of the existing large-area plate, and the middle part of the casting and welding mold 1 is slotted and narrowed, which reduces the volume of the casting and welding mold 1 and expands The surrounding heat dissipation area is improved, and the heat dissipation and heat absorption effect during the use of the mold are improved.

[0029] The bottom of the casting and welding mold 1 is provided with a tightly fitting upwardly convex cooling pipe section 8, and a side pipe body 9 is arranged on the bottom of each corner plate 4, and the side pipe body 9 is arranged to cooperate with the water inlet pipe 6 and the water outlet pipe 7 The detour lumen 10 is inserted into the detour lumen 10 and the heat dissipation guide rod 12 connected to the corner plate 4 is inserted into the heat dissipation guide rod 12, and a wide-mouthed water inlet wide mouth 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com