Rigid-flexible conversion positioning type special-shaped plate surface treatment process

A surface treatment and special-shaped technology, which is applied in the direction of manufacturing tools, grinding workpiece supports, metal processing equipment, etc., to achieve the effects of improving rigidity, uniform force, and improving efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

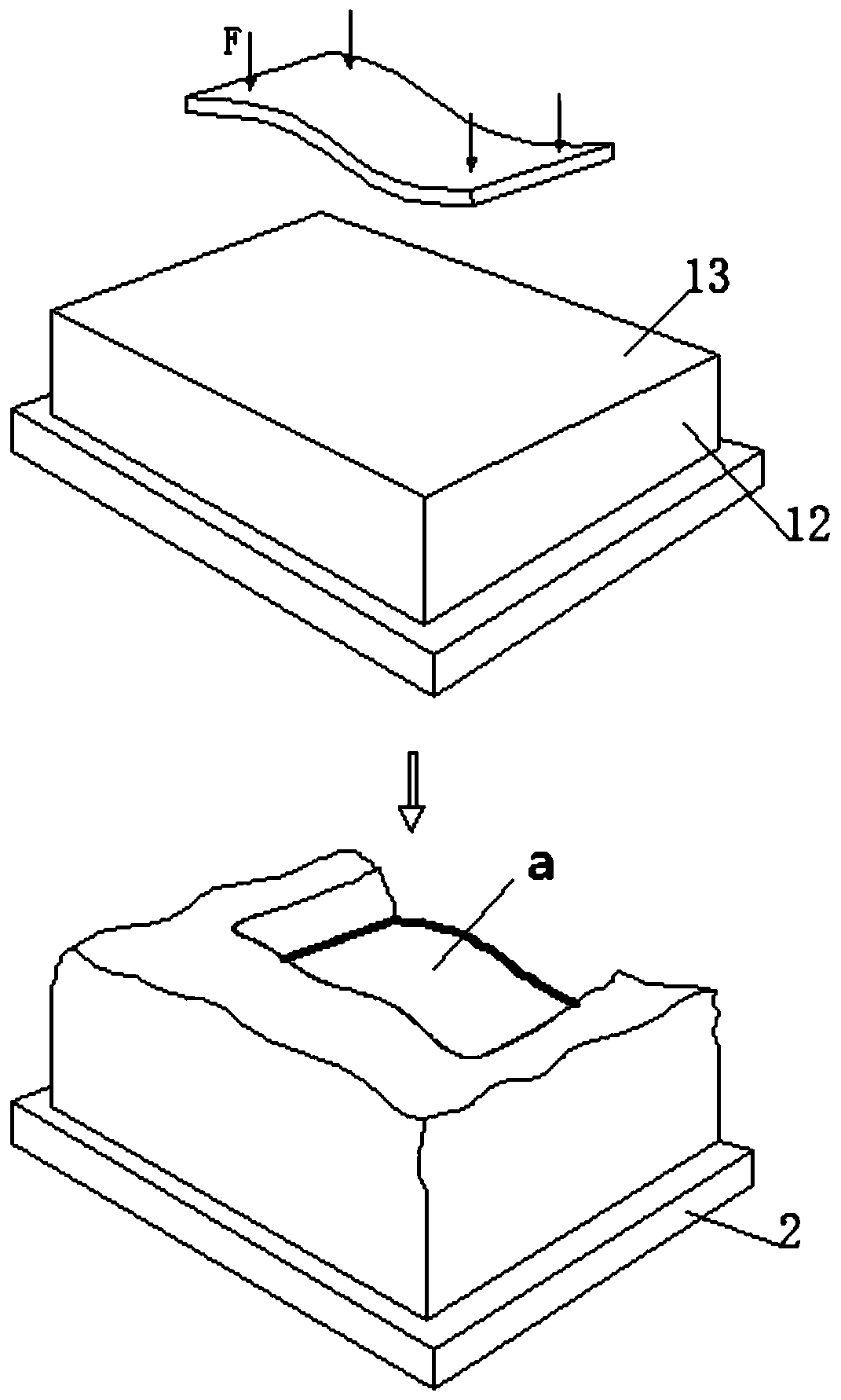

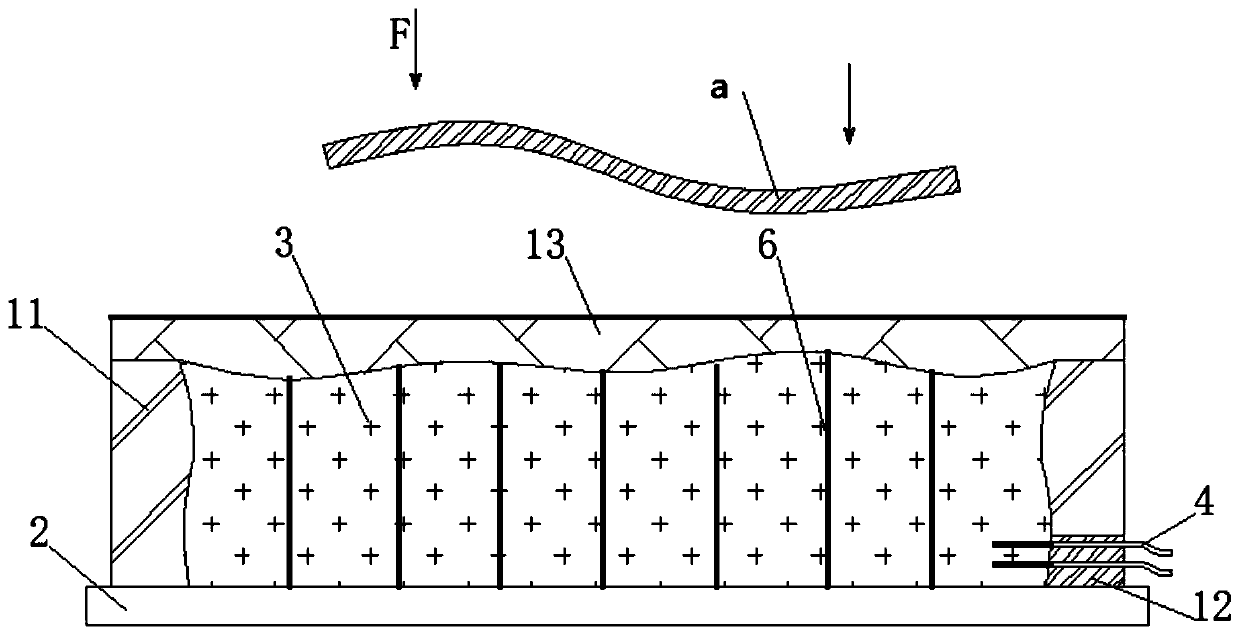

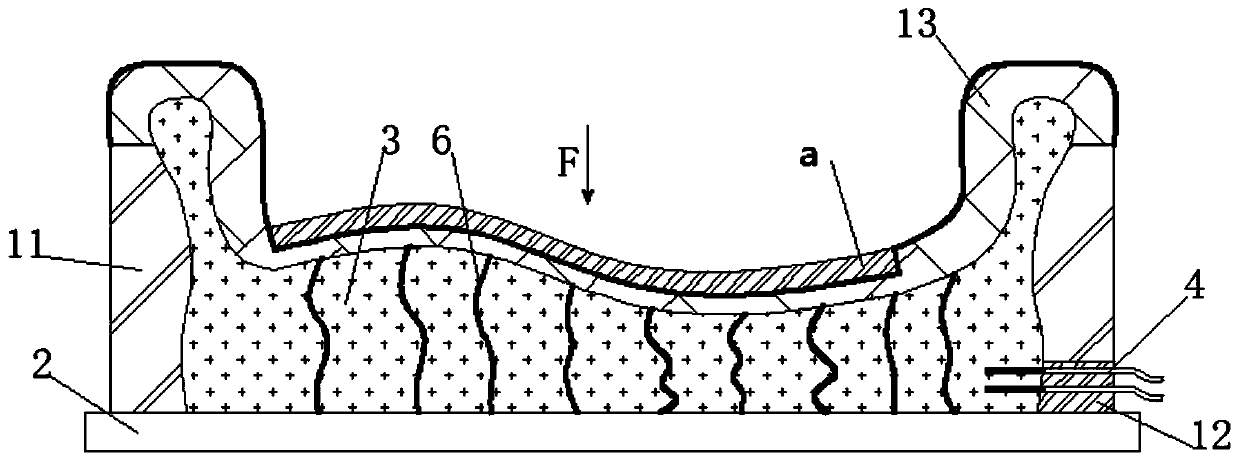

[0048] see figure 1 , a in the figure represents a special-shaped sheet, a surface treatment process for a rigid-flexible transformation and positioning of a special-shaped sheet, including the following steps:

[0049] S1. Firstly, the visual defects of special-shaped plates are preliminarily processed;

[0050] S2, then the special-shaped sheet is placed on the rigid-flexible deformation sheet-shaped plate;

[0051] S3. Simultaneously apply force to the special-shaped plate through multiple points from top to bottom, and the force applied at multiple points is the same, so that the force on the special-shaped plate is reduced;

[0052] S4. After that, the rigid-flexible deformation plate is energized, and the rigid-flexible deformation plate is converted from flexibility to rigidity, so that positioning grooves are formed on the surface of the rigid-flexible deformation plate. At this time, the upper surface of the special-shaped plate can be finely polished;

[0053] S5. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com