A honeycomb activated carbon scraping device for sewage treatment

A honeycomb activated carbon and sewage treatment technology, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. Simple, improve work efficiency, save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

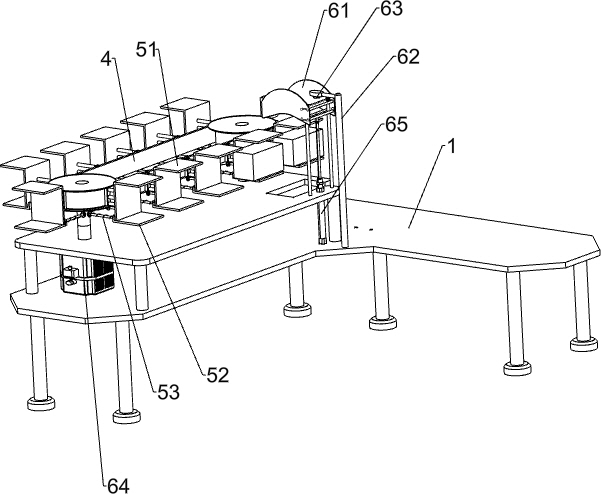

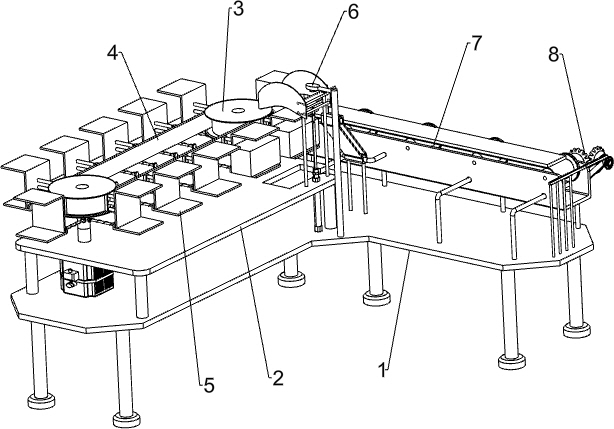

[0025] A kind of honeycomb activated carbon edge scraping device for sewage treatment, such as Figure 1-3 As shown, it includes a mounting seat 1, a fixed plate 2, a driving roller 3 and a transmission belt 4. The left side of the top of the mounting seat 1 is connected with a fixed plate 2, and the front and rear sides of the top of the fixed plate 2 are rotatably connected with a driving roller 3. A transmission belt 4 is wound between the driving rollers 3 , and a placing assembly 5 and an edge scraping assembly 6 are also included.

[0026] The placement assembly 5 includes a connecting plate 51, a sliding plate 52 and an elastic member 53. A plurality of connecting plates 51 are evenly spaced on the transmission belt 4. The bottom of the connecting plate 51 is slidably connected with a sliding plate 52. Between the sliding plate 52 and the connecting plate 51 An elastic member 53 is connected between them.

[0027] The edge scraping assembly 6 includes a scraper 61, a m...

Embodiment 2

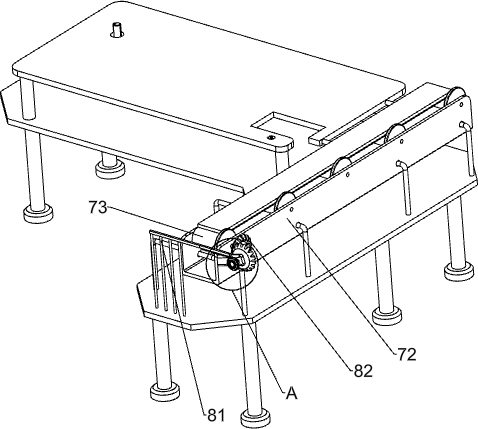

[0030] On the basis of Example 1, such as Figure 3-4 As shown, a mobile assembly 7 is also included, and the mobile assembly 7 includes a guide rail 71, a slide frame 72, a conveyor belt 73, a placement plate 74 and a guide frame 75, and a plurality of guide rails 71 are evenly spaced on the rear side of the top of the mounting seat 1. A slide frame 72 is slidably connected between the root guide rails 71, and a conveyor belt 73 is rotatably connected in the slide frame 72. A placement plate 74 is placed on the top of the conveyor belt 73, and the placement plate 74 and the slide plate 52 are at the same height. A guide frame 75 is connected between the mounting bases 1 , the guide frame 75 is slidingly matched with the mounting base 1 , and the guide frame 75 is matched with the sliding frame 72 .

[0031] The scraper 61 drives the guide frame 75 to move up and down together when moving up and down, and the guide frame 75 drives the slide frame 72 to move forward when moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com