An automatic grinding device for turning stones

A stone, automatic technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

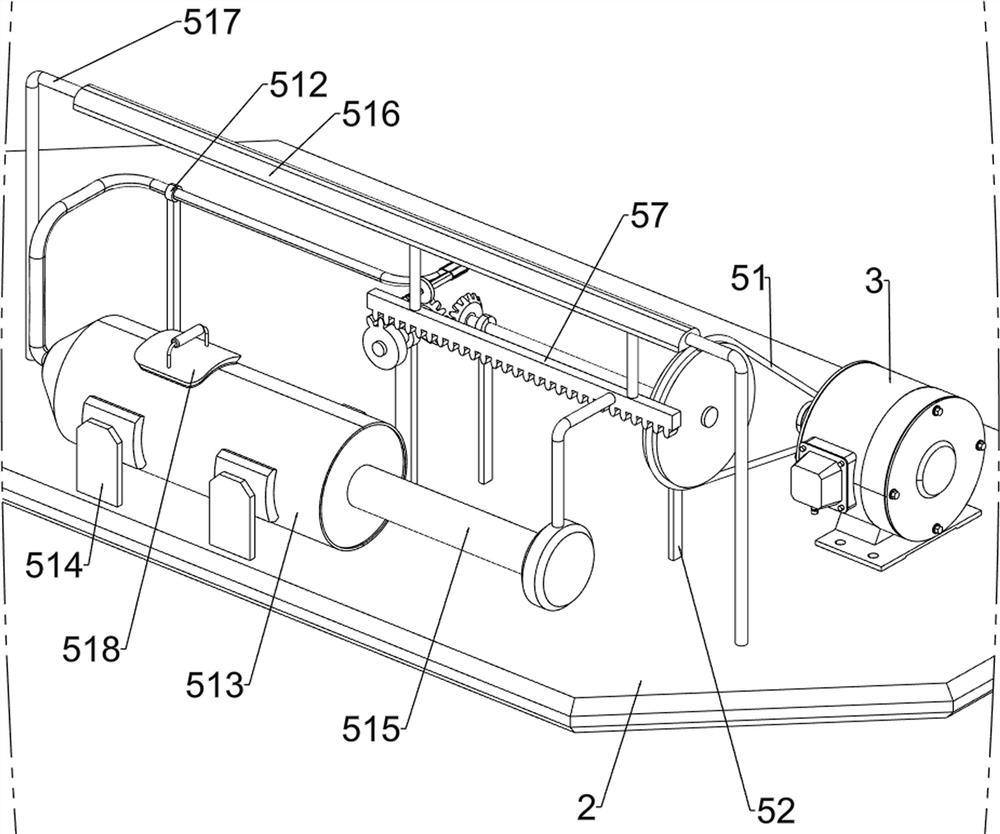

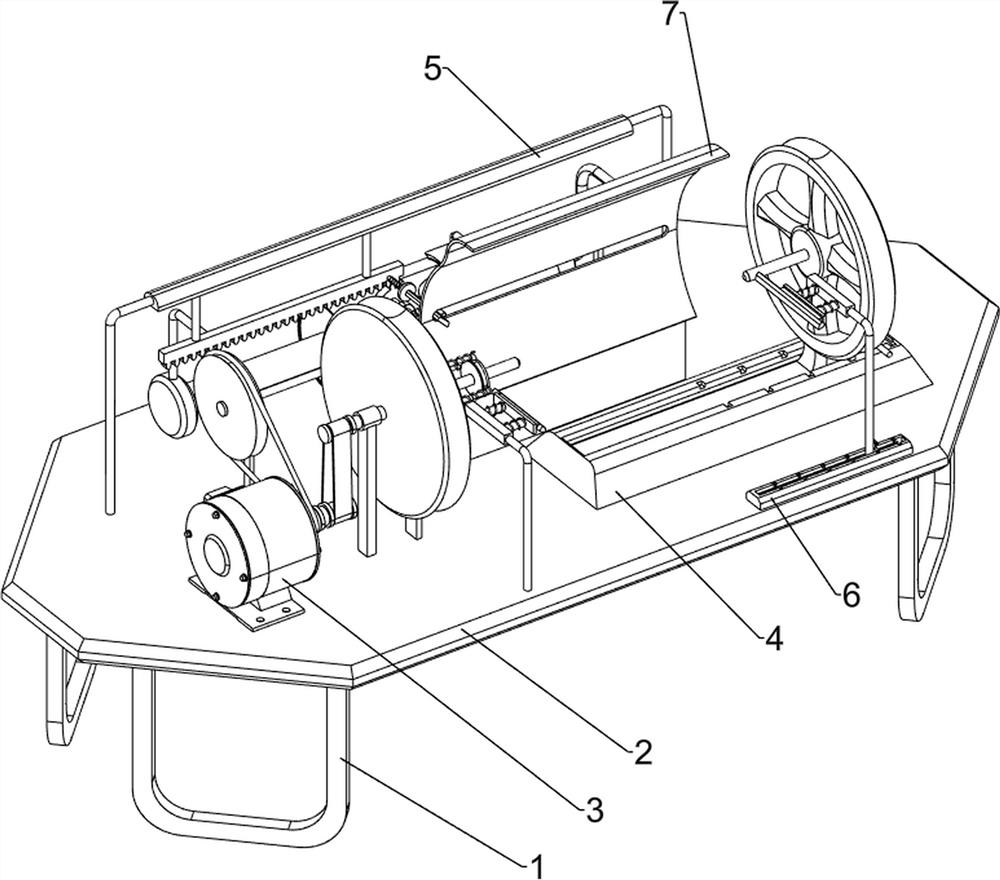

[0027] A car stone automatic grinding device, such as Figure 1-6 As shown, it includes a fixed bracket 1, a workbench 2 and a motor 3. The top of the fixed bracket 1 is connected to a workbench 2, and the left side of the top of the workbench 2 is connected to a motor 3. It also includes a fixed rotation mechanism 4 and a cutting water spray mechanism 5. , the worktable 2 is provided with a fixed rotating mechanism 4 and a cutting water spray mechanism 5 .

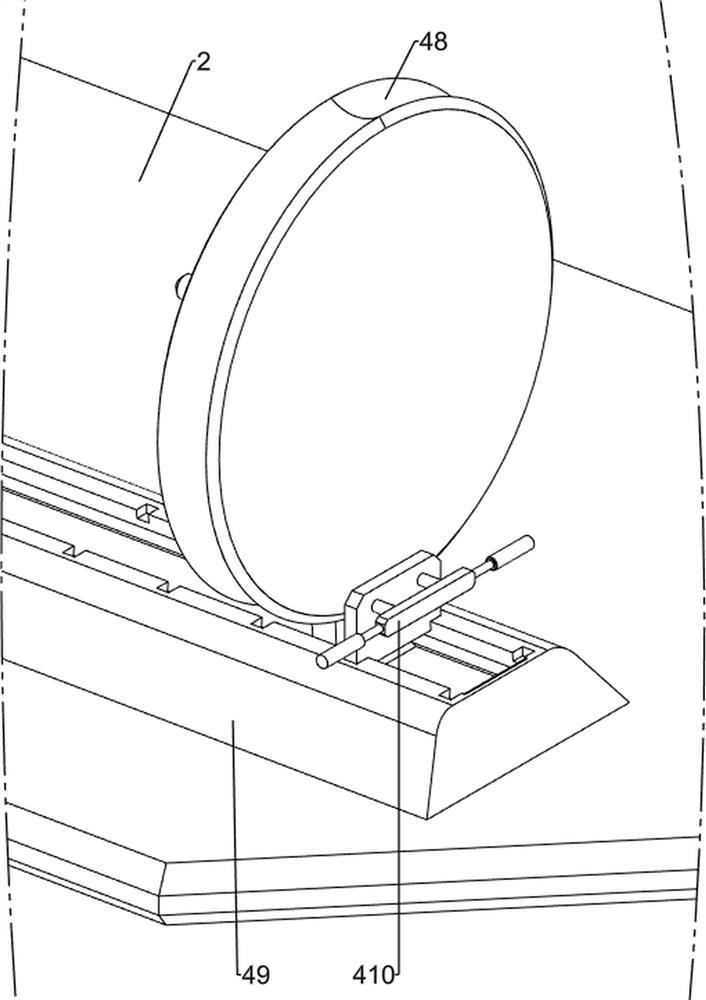

[0028] The fixed rotating mechanism 4 includes a first rotating shaft 41, a first transmission assembly 42, a first bearing column 43, a second rotating shaft 44, a rotating disk 45, a first fixed disk 46, a first spring assembly 47, a second fixed disk 48, The first slide rail 49 and the first baffle 410, the output shaft of the motor 3 is connected with a first rotating shaft 41, the top left side of the worktable 2 is connected with a first bearing column 43, and the first bearing column 43 is rotatably connected with ...

Embodiment 2

[0032] On the basis of Example 1, as Figure 7 As shown, it also includes a leveling mechanism 6. The leveling mechanism 6 includes a third sliding rail 61, a sliding column 62, a second baffle 63, a third spring assembly 64 and a scraper 65. The top right front side of the workbench 2 is connected with a The third slide rail 61, the left front side of the workbench 2 and the third slide rail 61 are connected with a slide column 62, the slide column 62 on the third slide rail 61 slides with the third slide rail 61, and the third slide rail 61 A second baffle 63 is snap-connected, and the second baffle 63 is detachable. The second baffle 63 is used to block the sliding column 62 on the third sliding rail 61, and the sliding column 62 is slidably connected with a scraper 65. A third spring assembly 64 is connected between the scraper 65 and the sliding column 62 .

[0033] When placing the stone, the two sides of the stone will be in contact with the scrapers 65 on both sides r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com