Medical operation towel processing assembly line

A surgical towel and assembly line technology, which is applied in the field of medical surgical towel processing assembly line, can solve the problems of inability to realize assembly line automation, low degree of automation, and low production efficiency, and achieve the effects of compact structure, capital saving, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

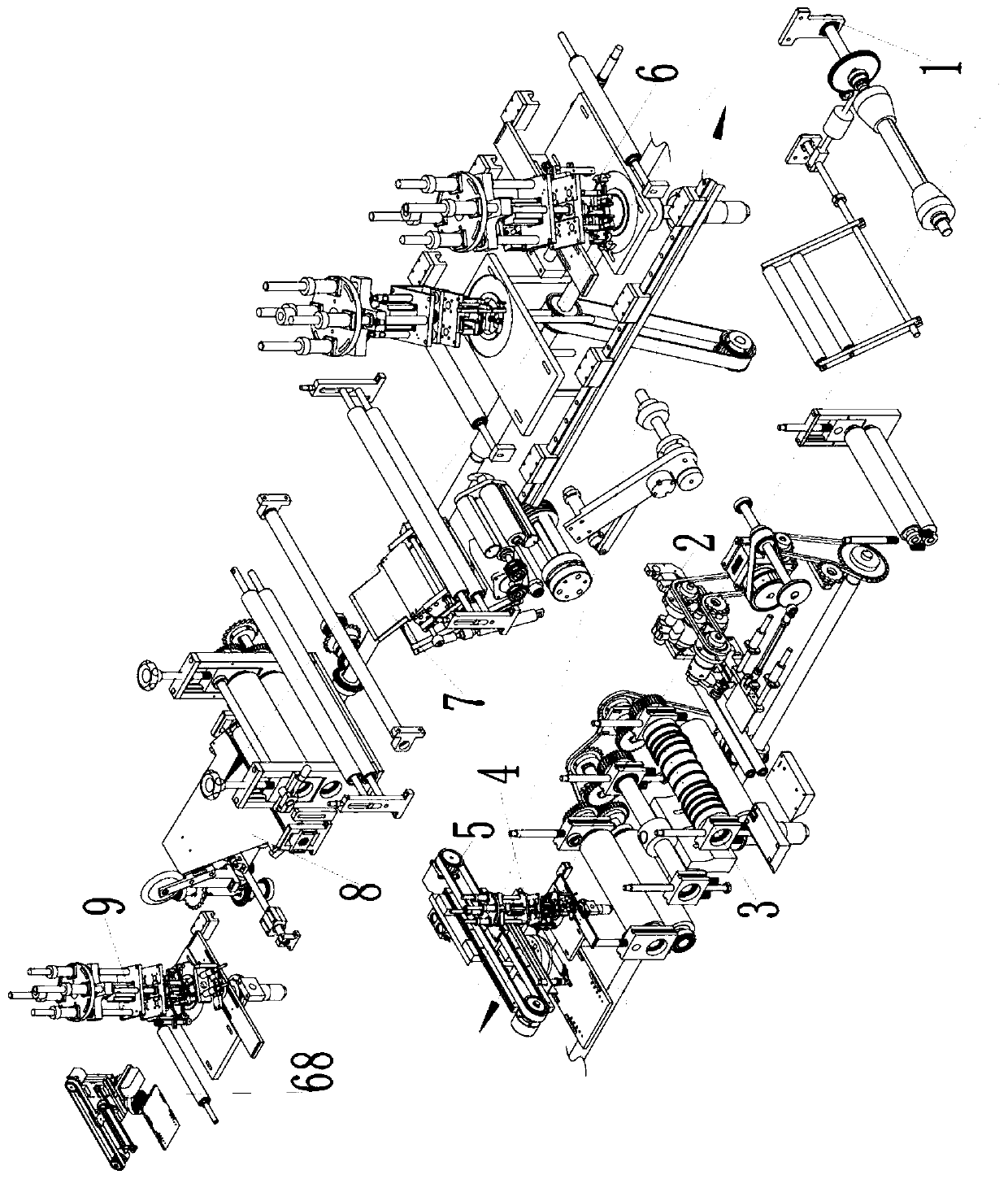

[0082] like Figure 1-8 As shown, the medical surgical towel processing line of this embodiment includes a first cloth loading device 1, an intermediate cloth loading device 2, a medical surgical towel processing system, a third cloth loading device 7, a third cloth loading device 7, a secondary processing Device 8, total sewing device 9 and the third hot stamping device 68;

[0083] The first cloth loading device 1 is used to send the first layer of fabric towels in;

[0084] The middle cloth loading device 2 is used to feed the middle layer fabric towel;

[0085] The medical surgical drape processing system is used to process the first layer of fabric drape and the middle layer of fabric drape into a composite surgical drape; it includes a primary rolling device 3, a primary sewing device 4, a pretreatment device 5 and a secondary sewing device 6;

[0086] The third cloth loading device 7 is used to send in after tearing off the packaging of the third layer of fabric towel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com