An Intelligent Spinning Management System

A management system and spinning technology, applied in the field of spinning, to achieve the effects of synchronous and fixed-point detection, efficient monitoring and prevention, and improving spinning efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

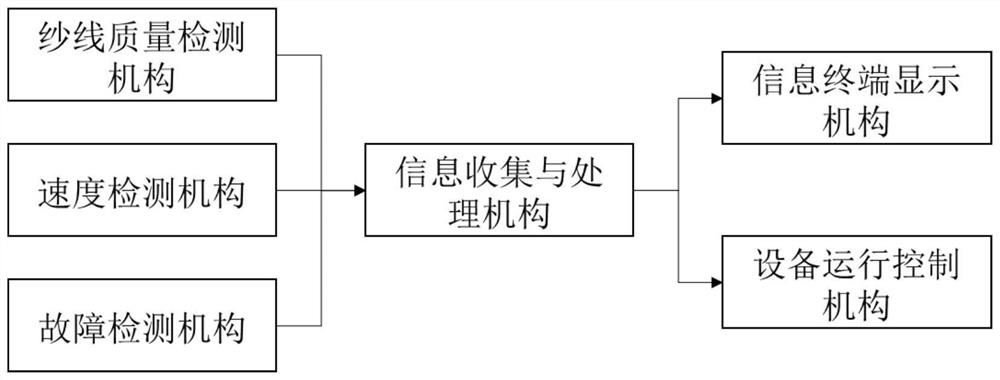

[0041] see figure 1 As shown, the intelligent spinning management system provided by the present invention includes:

[0042] The yarn quality detection mechanism is used to detect the quality of the fed thick yarn and the fine yarn after twisting;

[0043] The equipment operation detection mechanism is used to detect the operating parameters of the spinning equipment;

[0044] The fault detection mechanism is used to detect the running state of the spinning equipment;

[0045] The information collection and processing mechanism is used to collect and process the data detected by the yarn quality detection mechanism, the equipment operation detection mechanism and the fault detection mechanism, and obtain the instruction signal of the spinning equipment;

[0046] The information terminal display mechanism is used to display the indication signal of the spinning equipment; and,

[0047] Equipment operation control mechanism, used to control the operation of spinning equipmen...

Embodiment 2

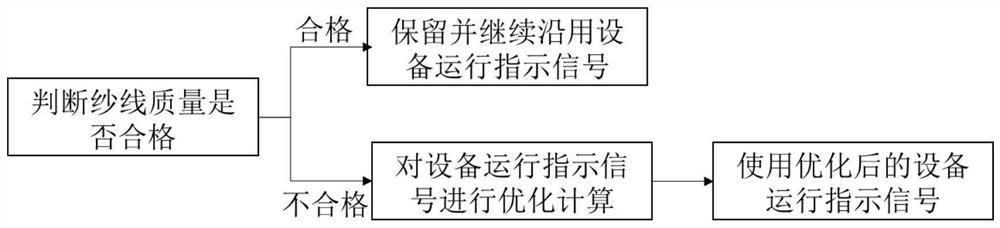

[0078] see figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 is that the information collection and processing mechanism also includes an equipment operation optimization unit, and the optimization method of the equipment operation optimization unit includes the following steps:

[0079] S1. The equipment operation optimization unit first judges whether the quality of the wound and formed yarn is qualified according to the fineness data and strength data of the twisted spun yarn detected by the yarn quality detection mechanism;

[0080] S2. If qualified, then retain the equipment operation indication signal of the twisted spun yarn, and send the equipment operation indication signal of the twisted spun yarn to the equipment operation control mechanism for the next step Batch spinning process;

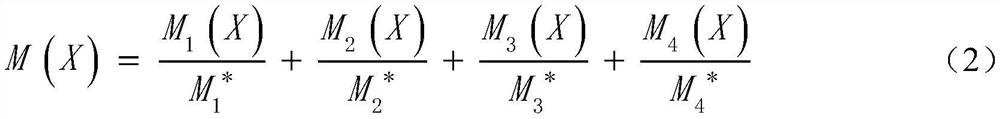

[0081] S3. If it is unqualified, according to the deviation value between the fineness data and strength data of the twisted spun yarn and the target value, opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com