Fixing device for underground pipe gallery installation and using method for fixing device

A technology for fixing devices and underground pipe galleries, applied in underwater structures, water conservancy projects, artificial islands, etc., can solve the problems of poor assembly of roof and side plates, affecting the convenience of pipe gallery installation, and uneven pouring of pipe galleries , to achieve the effect of improving the structural strength, enhancing the overall structural strength and reducing the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

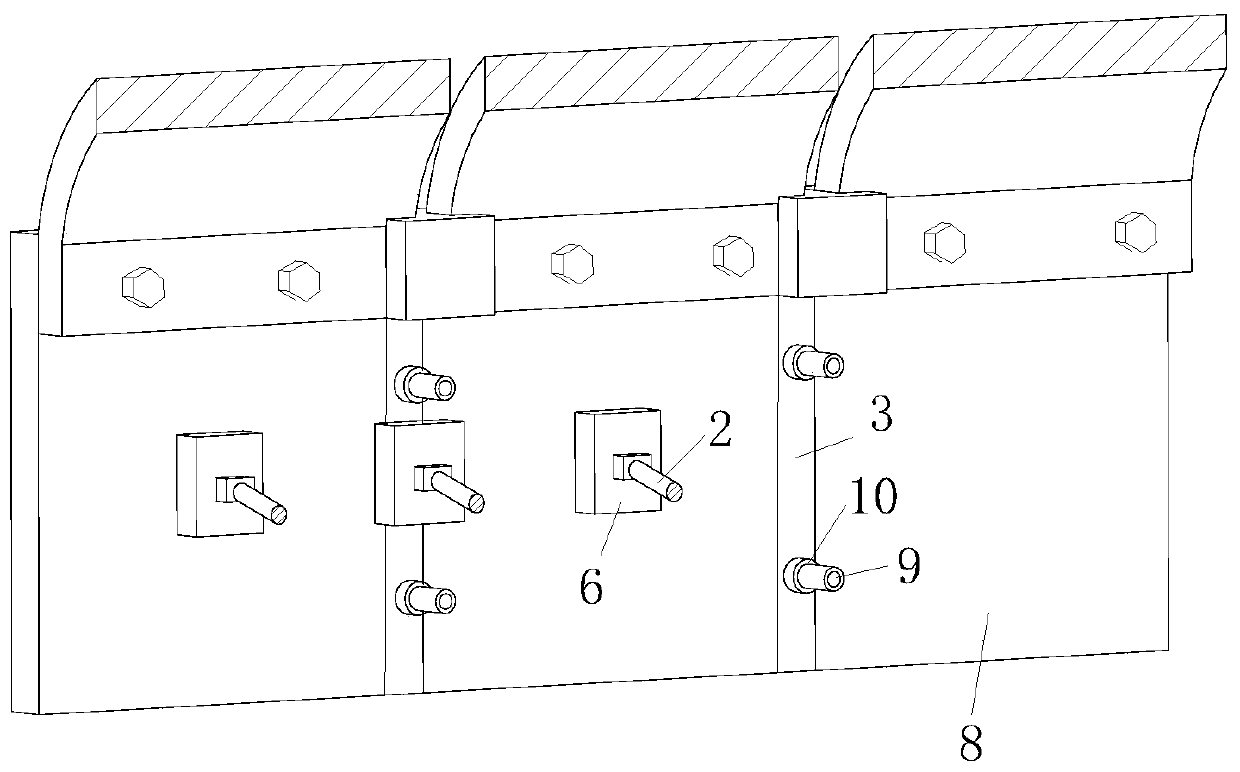

[0030] As an embodiment of the present invention, one side of the insertion rod 9 is arranged in an arc shape, wherein two swing plates 11 are hinged at one end of the arc shape of the insertion rod 9 ; the two swing plates 11 are symmetrically distributed. When working, the other end of the insertion rod 9 is arranged in an arc shape, which can have a better grip on the filling block 3 after being inserted into the soil. At the same time, the swing plate 11 provided at the end of the insertion rod 9 can be inserted into the soil The force swings and opens, thereby further increasing the contact area with the soil, so that the pulling effect of the insertion rod 9 on the filling block 3 is further enhanced.

[0031] As an embodiment of the present invention, the insertion rod 9 is provided with a cylindrical through groove 12; a sliding rod 13 is inserted into the cylindrical through groove 12; Two connecting rods 14 are hinged at one end of the sliding rod 13 close to the swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com