A connection structure and construction method of a prefabricated rail top air duct and a structural slab

A rail-top air duct and connecting structure technology, applied in the field of rail transit, can solve the problems of difficult to guarantee construction quality, narrow rail-top air duct space, easy to leave quality hidden dangers, etc., achieving fast construction speed, saving construction time and cost, The effect of a reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

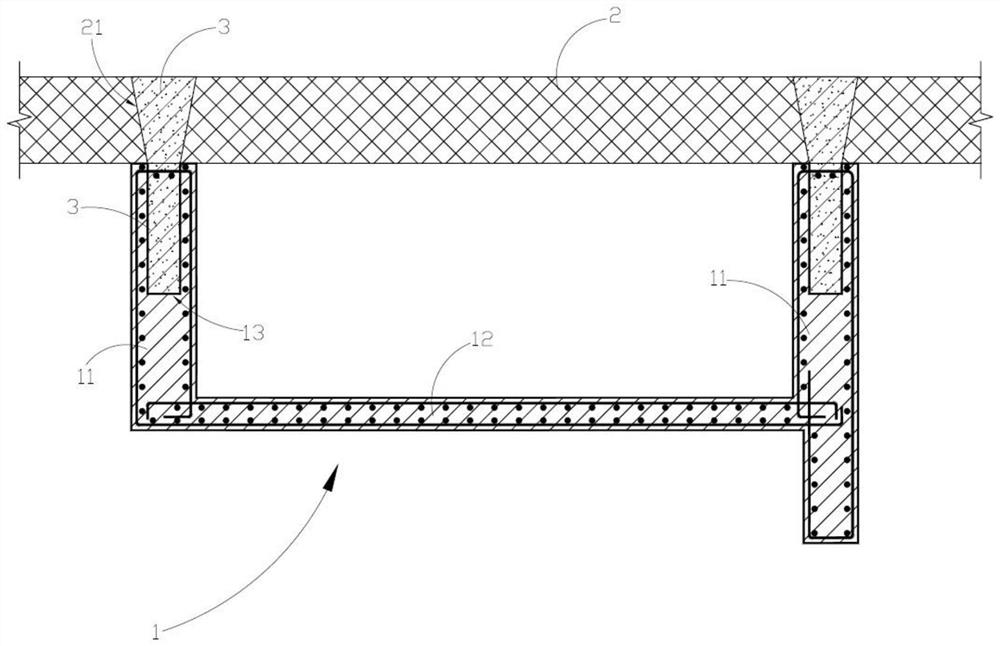

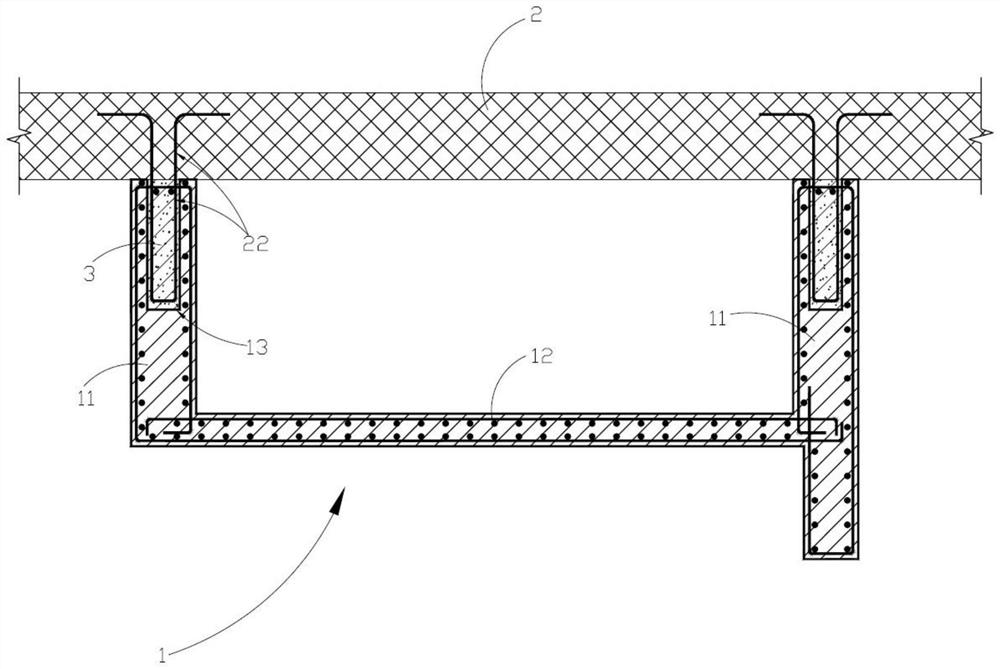

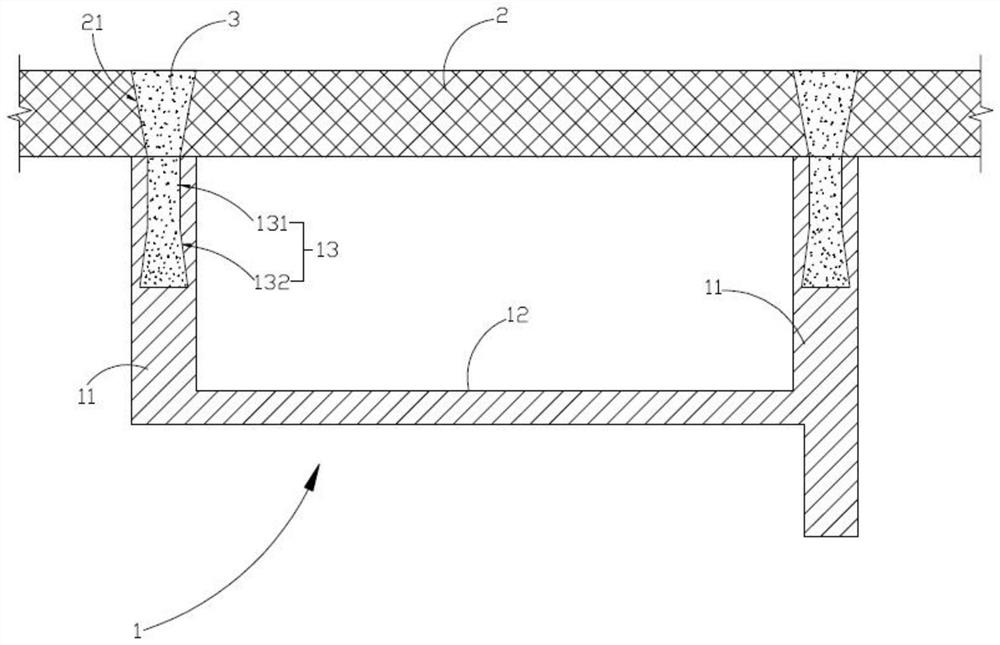

[0031] Such as Figure 1-Figure 3 , the embodiment of the present invention provides a prefabricated rail roof air duct, including a plurality of air duct units 1 spliced in sequence along the longitudinal direction of the air duct, each of the air duct units 1 includes a bottom plate 12 and at least two connected to the bottom plate 12 Each side plate 11, in each of the air duct units 1, at least one of the side plates 11 is provided with a pouring groove 13 for pouring concrete 3 on the top.

[0032] The above-mentioned bottom plate 12 is connected with at least two side plates 11 to form a groove structure, wherein the above-mentioned air duct unit 1 can adopt the structural shape of the area where the screen door is hung below, that is, it has a vertical wall, and the bottom plate 12 is connected to the middle of the side plate 11; In other embodiments, it can also be used in a structure without a vertical wall, and the bottom plate 12 is connected to the bottom end of t...

Embodiment 2

[0044] Such as Figure 1-Figure 5 , the embodiment of the present invention provides a connection structure between the rail top air duct and the structural plate 2, including the rail top air duct and the structural plate 2, the rail top air duct includes a plurality of air duct units 1 sequentially spliced along the longitudinal direction of the air duct, each of which The air duct units 1 are all prefabricated structures, the top of each of the air duct units 1 is provided with pouring grooves 13, the structural plate 2 is provided with a plurality of pouring holes 21, and each of the pouring holes 21 is connected with one of the pouring holes. The pouring grooves 13 are connected, and each of the air duct units 1 is solidified on the bottom of the structural plate 2 through the cast-in-place concrete 3 poured in each of the pouring holes 21 and each of the pouring grooves 13 . Wherein, the rail top air duct preferably adopts the prefabricated rail top air duct provided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com