Building material drying device

A technology for drying devices and building materials, which is applied in drying, drying machines, heating devices, etc., and can solve the problems of limited moving range of stirring rods, single stirring form, and building materials that cannot be directly stirred by stirring rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

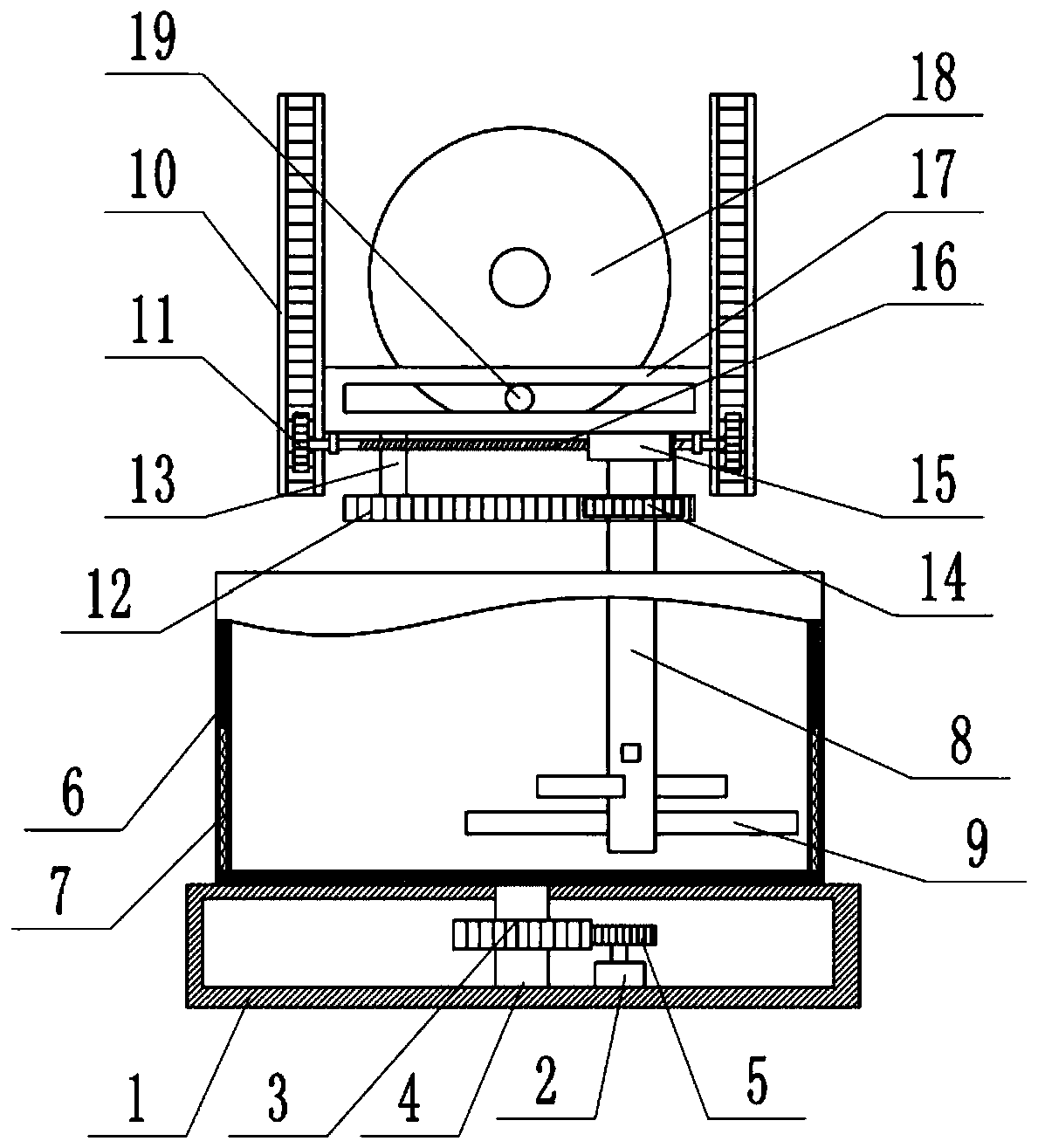

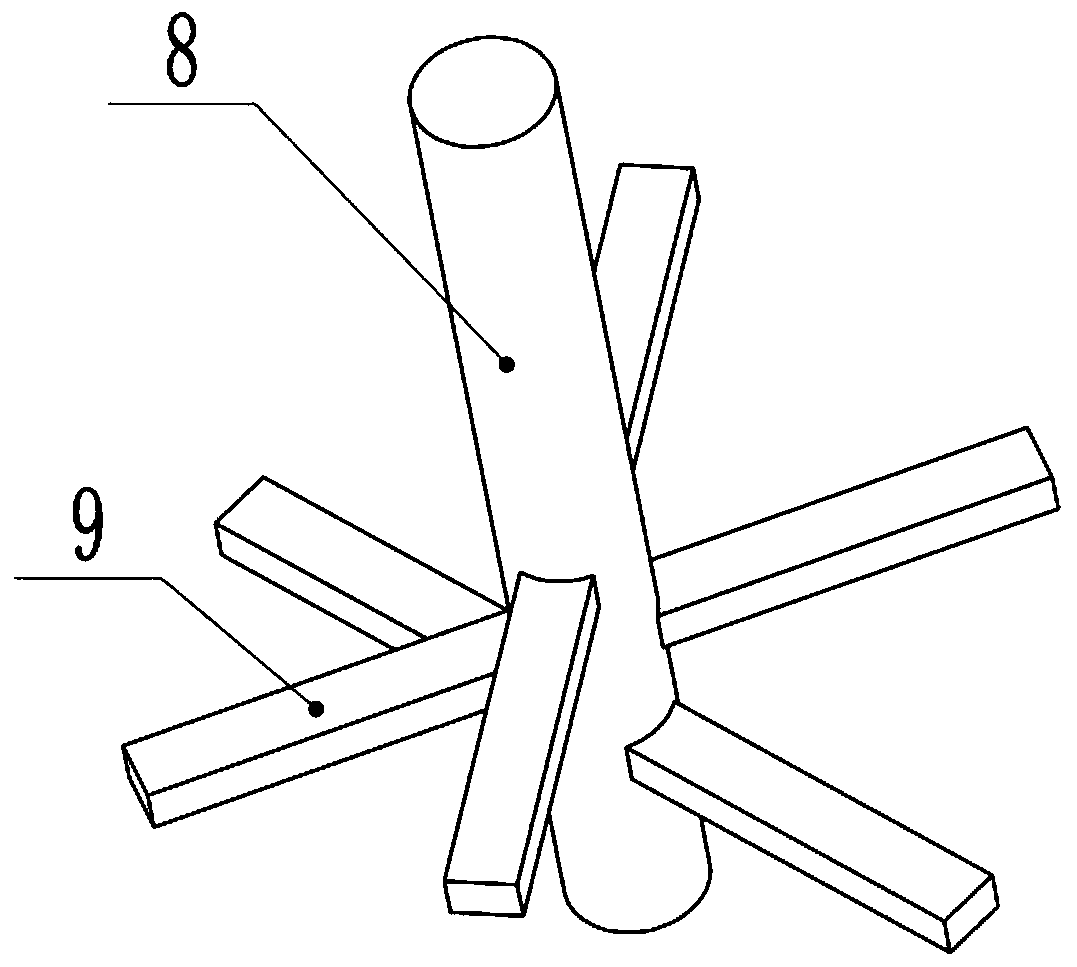

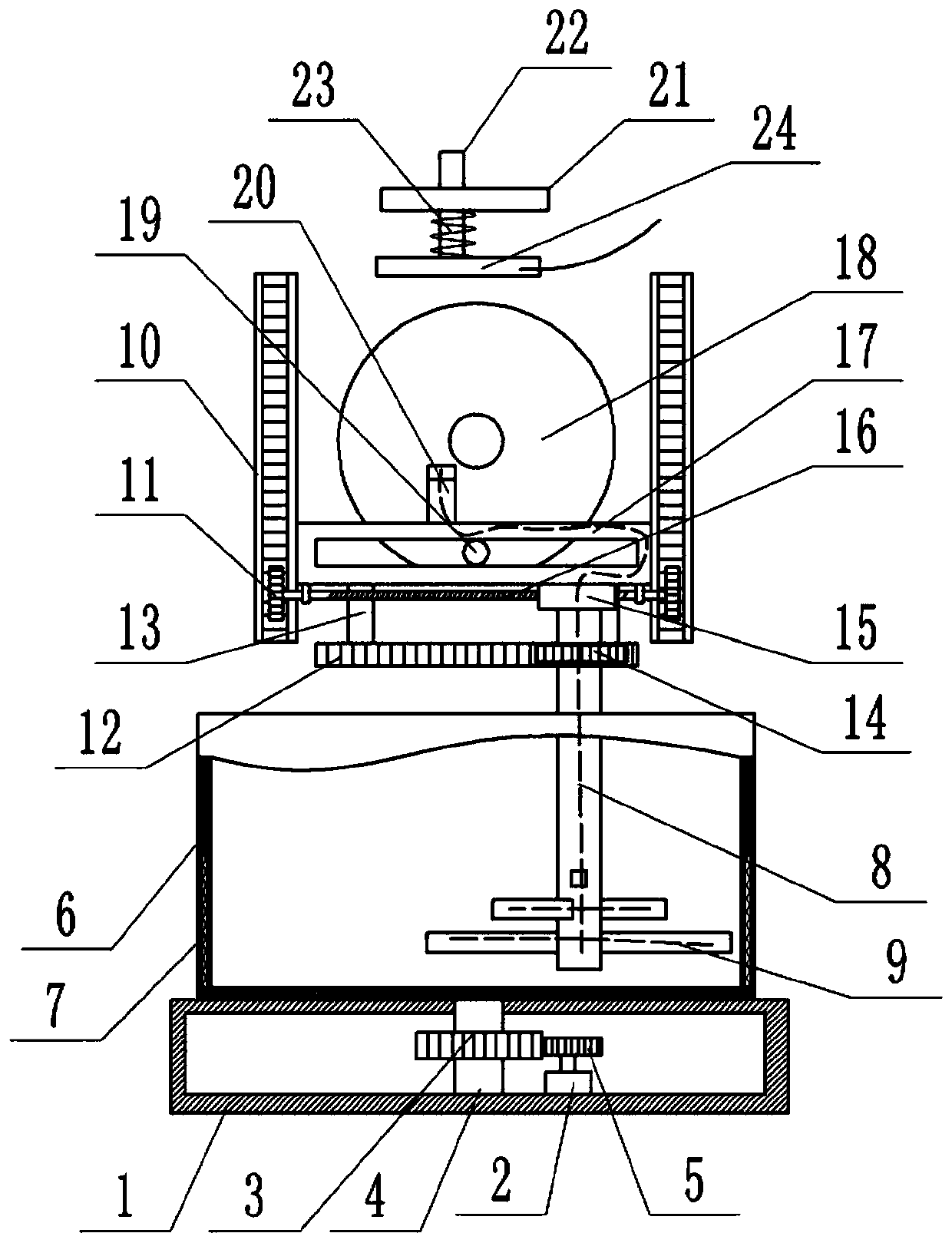

[0026] Basic as attached Figure 1-Figure 2 Shown: a drying device for building materials, including a frame, a base 1, a drying cylinder 6 with heating function, a stirring shaft 8 and a stirring rod 9, combined with figure 2 As shown, the stirring rods 9 are welded on the stirring shaft 8 , and the projections of the stirring rods 9 in the axial direction of the stirring shaft 8 are distributed in a staggered manner. The drying cylinder 6 is located on the base 1, and the drying cylinder 6 is rotatably connected to the base 1. Specifically, the bottom of the base 1 is provided with a drive chamber, and the motor 2 is fixed in the drive chamber by screws, and the output shaft of the motor 2 is passed through a flat The key is coaxially fixed with a driving gear 5, and the bottom of the base 1 is connected with a drive shaft 4 through bearing rotation, the top of the drive shaft 4 passes through the top of the base 1 and is welded to the bottom of the drying cylinder 6, and t...

Embodiment 2

[0038] combine Image 6 As shown, the stirring rod 9 in the present embodiment is provided with several material holes 25, the material holes 25 vertically penetrate the stirring rod 9, the material holes 25 are stepped holes, and the diameter of the bottom end of the material hole 25 is greater than the diameter of the material hole 25 tops , the bottom of the feed hole 25 is provided with a baffle plate 27 hinged on the stirring rod 9, and the right end of the baffle plate 27 is provided with a torsion spring at the hinged position of the stirring rod 9, and the baffle plate 27 is under the elastic force of the torsion spring. The left end of 27 offsets with the bottom of material hole 25, and baffle plate 27 is horizontal state, and baffle plate 27 blocks material hole 25. On the left end top of baffle plate 27, be fixedly connected with magnet 28 by screw, the bottom of material hole 25 is fixedly connected with electromagnet 26 by screw, when electromagnet 26 was energize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com