grain dryer

A grain dryer and grain technology, applied in the field of grain dryers and grain drying devices, can solve the problems of limitation, broken grains, time-consuming and labor-intensive, etc., and achieve the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

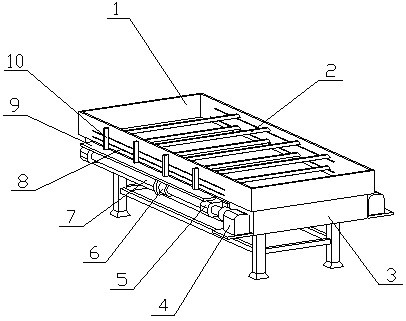

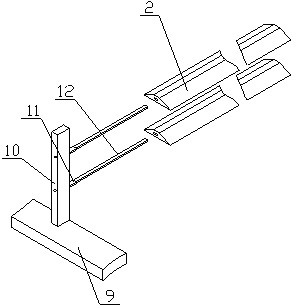

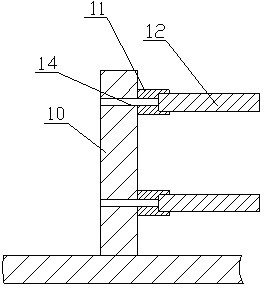

[0020] The grain drying machine of the present invention is realized in this way: the grain drying machine of the present invention consists of a drying box (1), a drying sheet (2), a bracket (3), a stepping motor (4), a mounting seat (5), and a ball screw cover (6), ball screw (7), sliding groove (8), moving plate (9), moving seat (10), moving block (11), heating core (12) and wiring hole (14), the said The drying box (1) is fixedly placed on the top of the support (3), and there are multiple sliding slots (8) on the two opposite sides of the drying box (1), and the sliding grooves (8) on a single side of the drying box (1) The slots (8) are arranged longitudinally, the positions of the sliding slots (8) on the two sides of the drying box (1) are staggered, and the two stepping motors (4) are respectively fixed on both sides of the bracket (3) close to one end One end of the two ball screws (7) and the motor shafts of the two stepping motors (4) are connected in one-to-one co...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is: there are triangular grooves (13) on both sides of the drying sheet (2); when in use, the contact area between the drying sheet (2) and the grain can be increased to improve the drying efficiency;

[0027] The design that the thickness of the drying sheet (2) gradually decreases from the middle to both sides can facilitate the movement of the drying sheet (2) to both sides, reduce the resistance when moving, and increase the contact area with the grain inside the drying box (1) at the same time , improve the drying effect;

[0028] The mobile seat (10) on both sides of the drying box (1) is designed with a plurality of wiring grooves, after the wiring on both sides of the drying box (1) can be connected uniformly, all the heating cores (12 ) for power-on work, to avoid too many external wires affecting the normal use of the device;

[0029] The bottom side of the drying box (1) is designed with a grain outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com