Laser ultrasonic imaging detection system and detection method for self-adaptive irregular surface

A laser ultrasonic and imaging detection technology, applied in optical testing of flaws/defects, analysis of solids using sonic/ultrasonic/infrasonic waves, and measurement devices, etc. , to achieve the effect of rapid identification and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

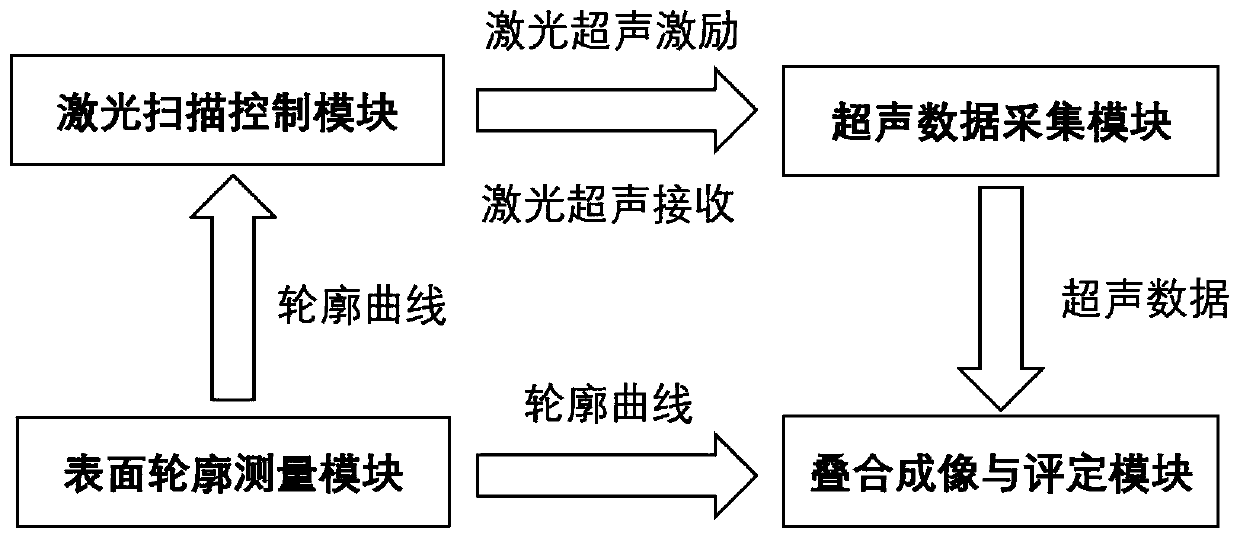

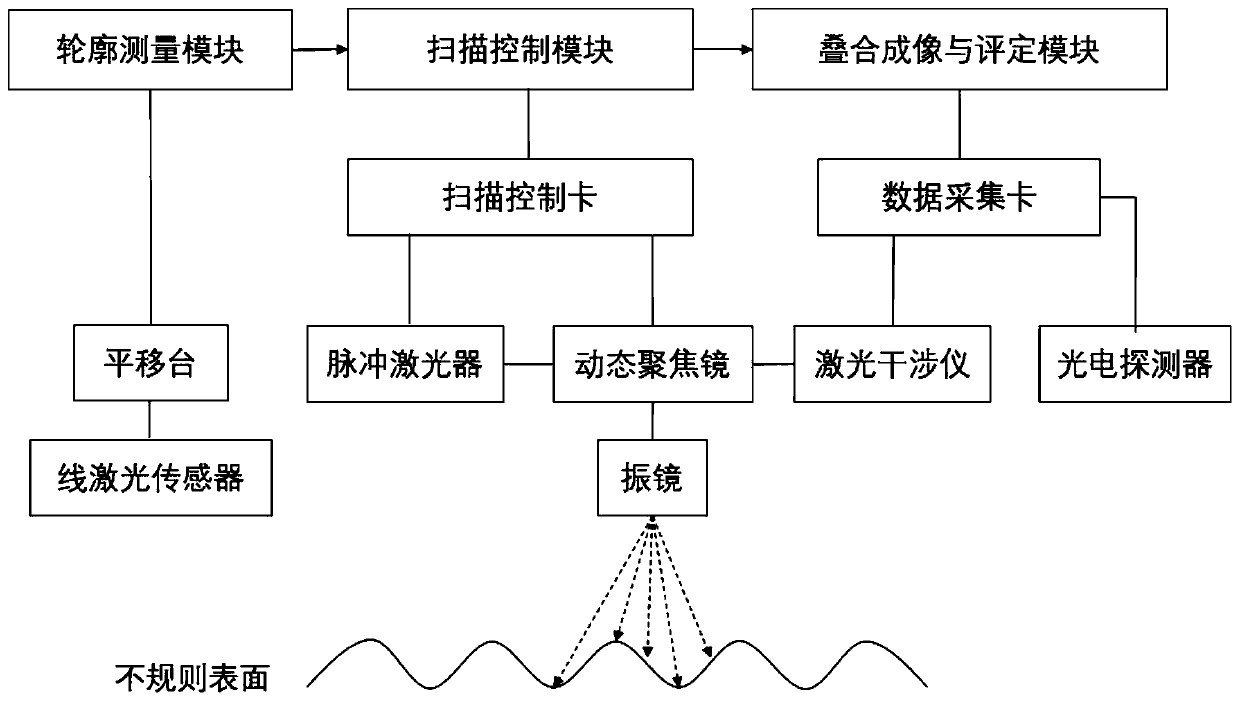

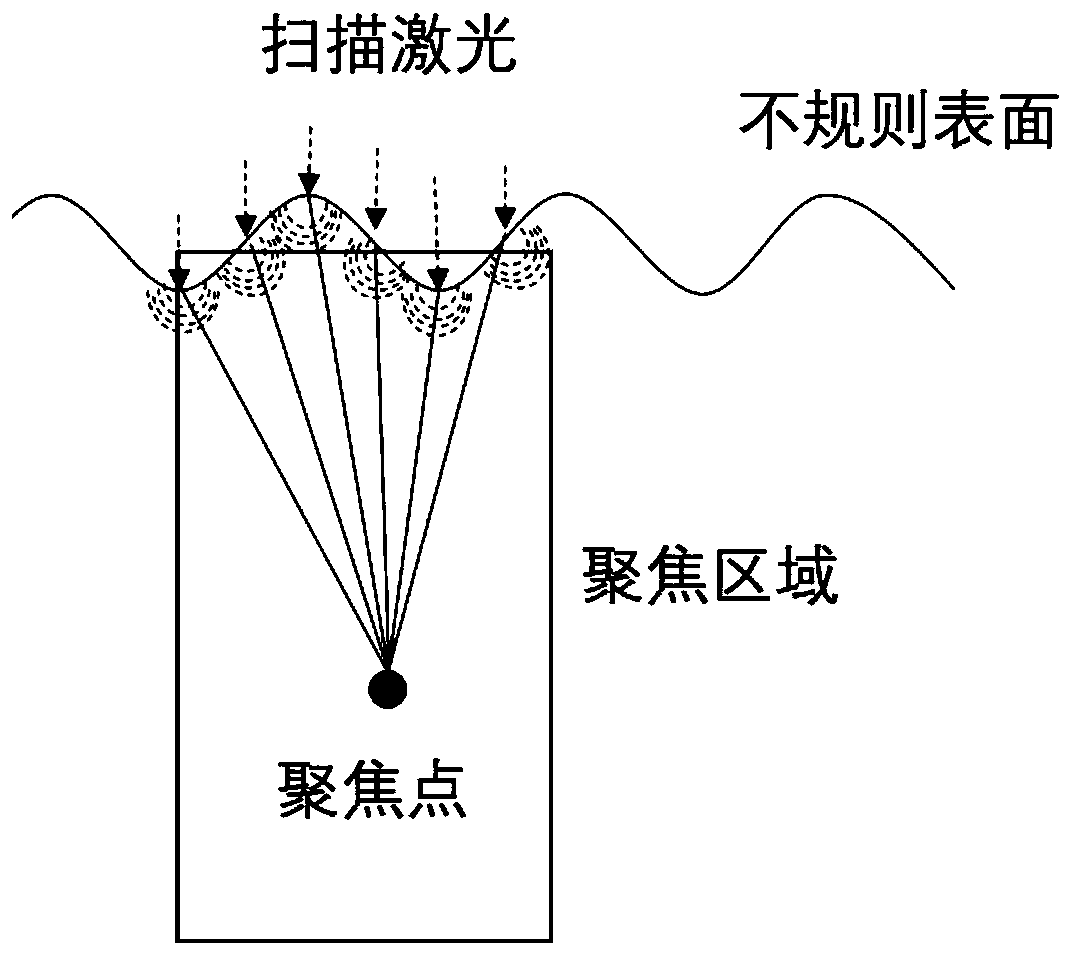

[0030] like figure 1 As shown, a self-adaptive irregular surface laser ultrasonic imaging detection system includes a surface profile measurement module, a laser scanning control module, an ultrasonic data acquisition module, and a composite imaging and evaluation module. The surface profile measurement module is connected with the laser scanning The control module is connected with the superimposed imaging and evaluation module, which is used for the measurement of the contour shape of the workpiece and the transmission of data; the laser scanning control module and the ultrasonic data acquisition module are two independent modules, which work synchronously and cooperatively to realize the laser ultrasonic signal respectively Stimulation and reception; the superimposed imaging and evaluation module performs virtual focusing processing on the laser ultrasonic signal and superimposed imaging display on the surface contour of the workpiece to identify and locate defects and struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com