MMC converter valve submodule online monitoring method and system

A sub-module and converter valve technology, applied in the electrical field, can solve the problems of inaccurate and intuitive health assessment of the MMC converter valve sub-module, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

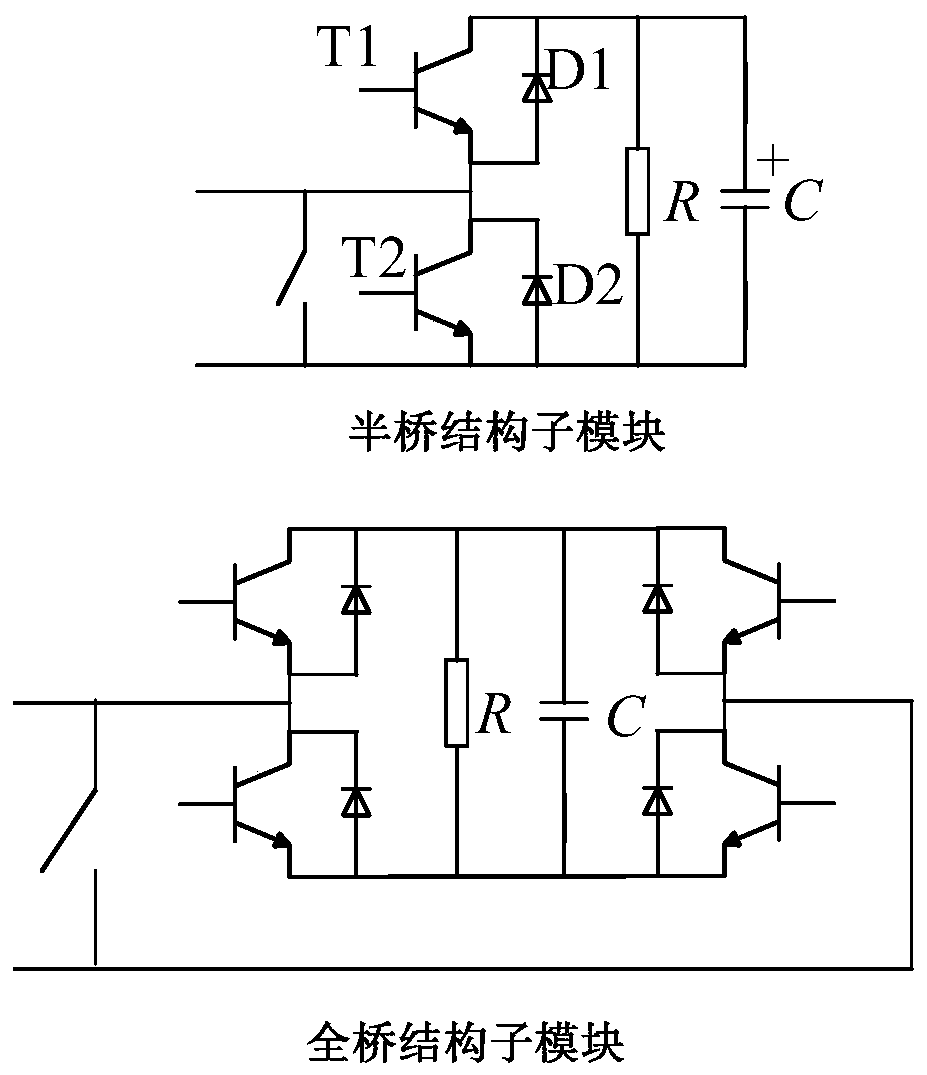

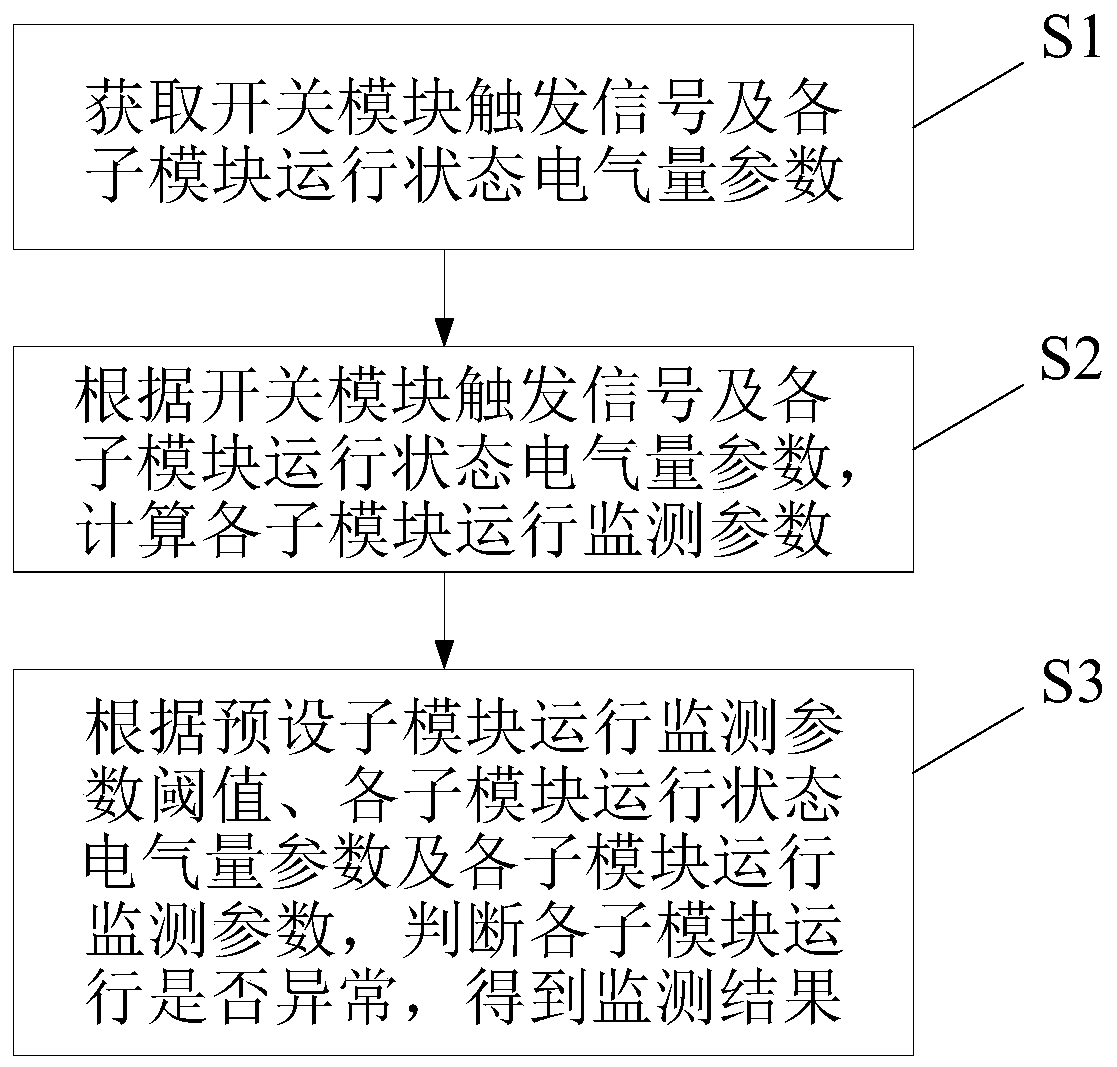

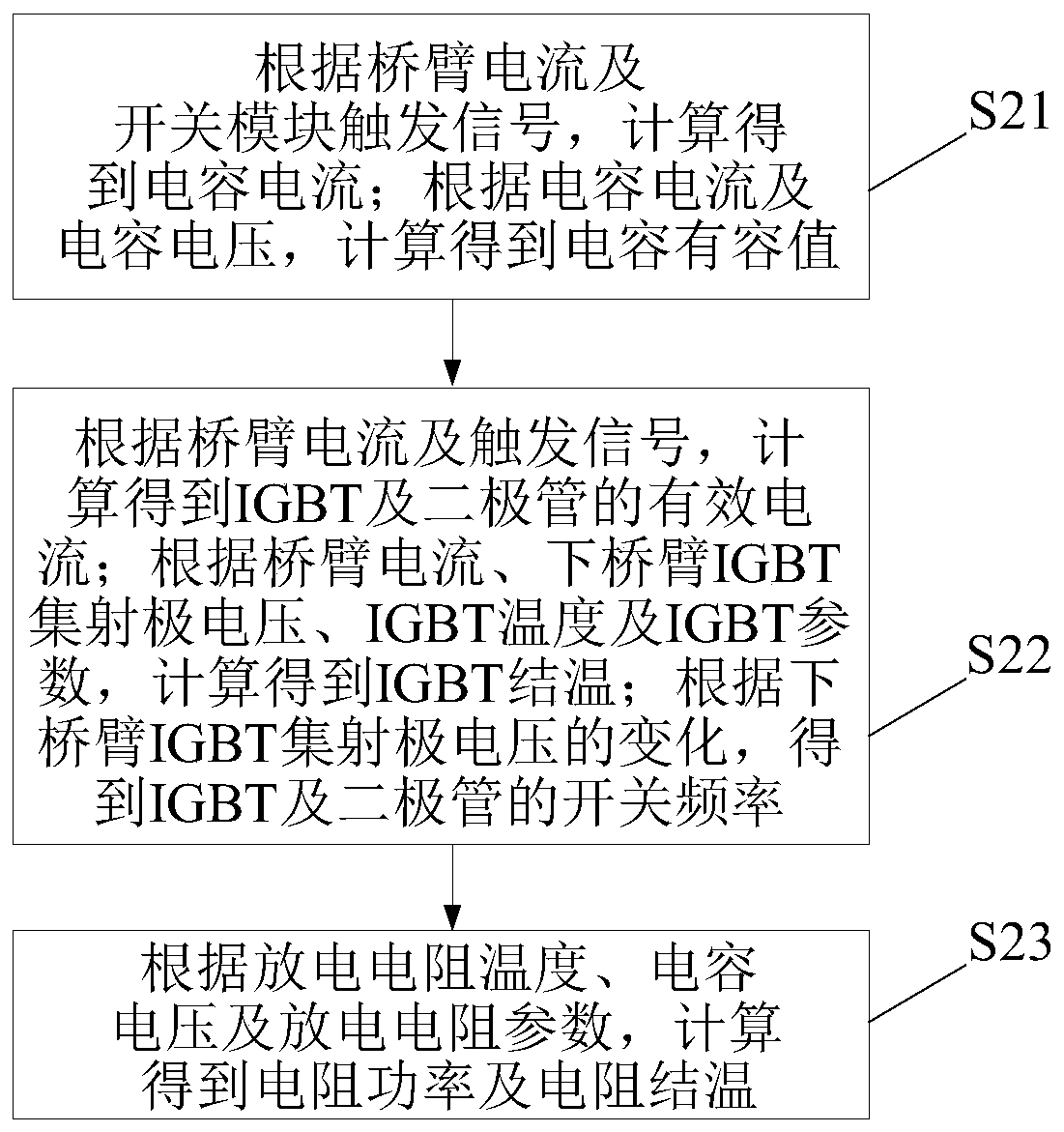

[0030] An embodiment of the present invention provides an online monitoring method for an MMC converter valve sub-module, which is applied to occasions where various components in a large-scale MMC converter valve sub-module need to be monitored. The MMC converter valve sub-module includes a plurality of switch modules, Discharge resistors and capacitors, multiple switch modules form a bridge circuit structure, discharge resistors and capacitors are connected in parallel with the bridge circuit, MMC converter valve sub-modules such as figure 1 as shown, figure 1 The switch module in the structure constitutes a half-bridge structure or a full-bridge structure. The switch module is composed of an IGBT connected in antiparallel with a diode. In addition, multiple switch modules can simultaneously form a three-phase converter valve, a half-wave converter, etc., and the switch module can be composed of Other components, such as MOSFET, GTO, etc. like figure 2 As shown, online mo...

Embodiment 2

[0075] An embodiment of the present invention provides an online monitoring system for an MMC converter valve sub-module, which is used to implement the online monitoring method for an MMC converter valve sub-module described in Embodiment 1. MMC converter valve sub-module such as figure 1 As shown, the control device of the MMC converter valve includes a sub-module controller and a valve base controller, each sub-module corresponds to a sub-module controller, figure 1 The switching module in is composed of an IGBT antiparallel with a diode, but the switching module can also be composed of other switching components. like Figure 5 As shown, the online monitoring system includes: a parameter collection module 1 , a data collection module 2 and a data processing module 3 .

[0076] The parameter collection module is used to obtain the trigger signal of the switch module and the electrical quantity parameters of the operating status of each sub-module.

[0077] In the embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com