Temperature compensation type plastic optical system and manufacturing method thereof

An optical system and temperature compensation technology, which is applied in optics, optical components, installation, etc., can solve problems such as poor imaging effect and agglomeration changes, and achieve the effect of light weight, light system weight, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] When the temperature of the molded lens 2 changes, the refractive index of its material will change obviously, which will cause its effective focal length to change with the temperature. At the same time, affected by the temperature, the surface shape of the molded lens 2 will also change, which will also affect the effective focal length of the lens.

[0047] Using professional simulation software, it is possible to simulate and calculate when the temperature changes ΔT, the refractive index change Δn of the molded lens 2, and the effective focal length (EFL) change Δf1 caused by the refractive index change. At the same time, the surface shape change caused by the temperature change ΔT causes the change of the effective focal length (EFL) to be Δf2.

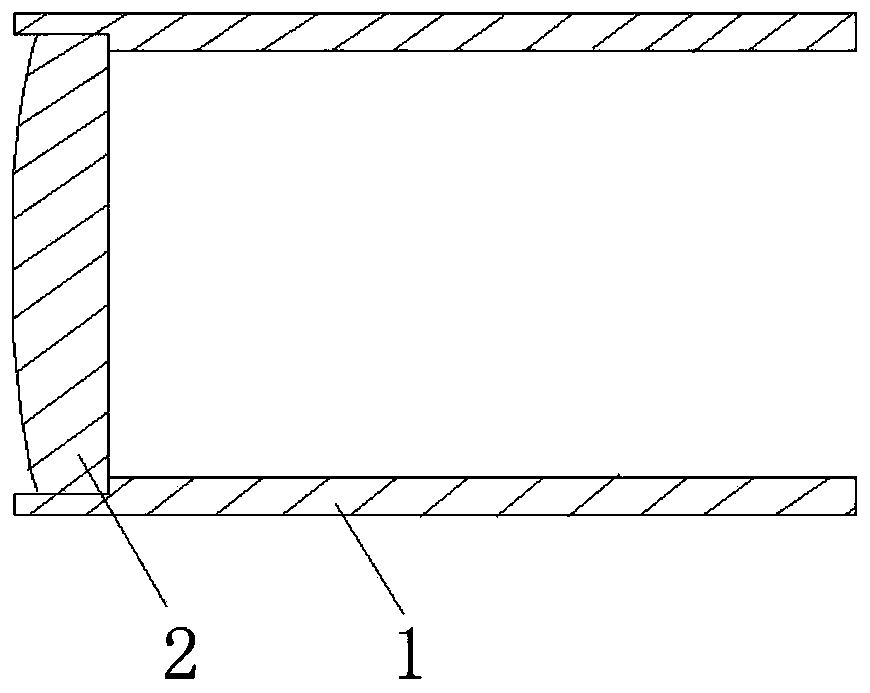

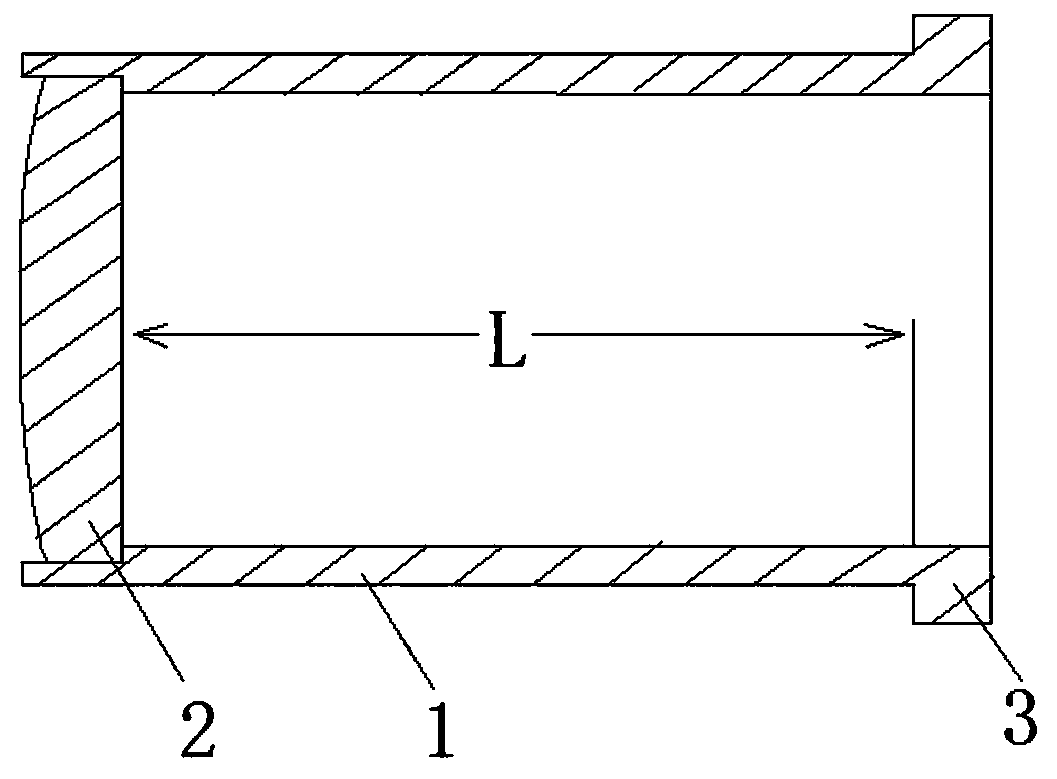

[0048] like figure 2 As shown, the plastic lens 2 and the plastic compensating shell 1 are bonded together, and the plastic compensating shell 1 is connected with a connection part 3, through which the connection part 3...

Embodiment 2

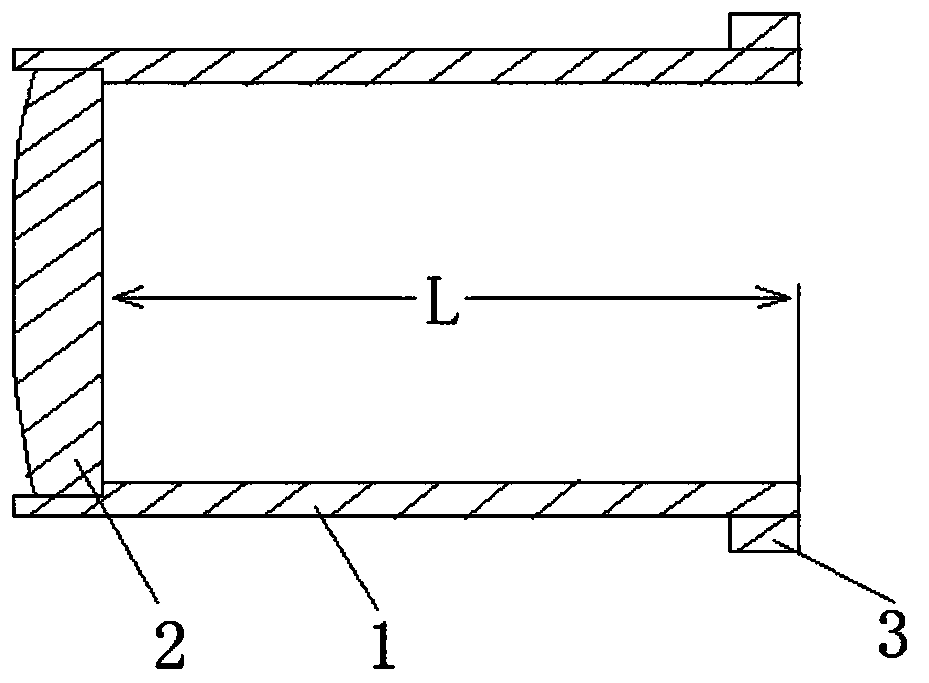

[0051] like image 3 As shown, the difference between the present embodiment and the first embodiment is that the connection part 3 is connected outside the plastic compensating housing 1 .

Embodiment 3

[0053] like Figure 4As shown, two groups of optical systems are provided, and multiple groups of optical systems can also be provided, which can be selected according to actual needs. In the figure, viewed from the right incident end to the left, there are plastic compensating housing 1 and plastic compensating housing 1 in turn. Plastic compensating housing 1 is provided with plastic lens 2 and plastic compensating housing 1 The plastic lens 2 is set in the second; the free expansion length of the plastic compensation housing 1 is L1, and the linear expansion coefficient of the plastic compensation housing 1 is at1; the length of the plastic compensation housing 1 is L2, and the plastic compensation housing 1 is L2. The coefficient of linear expansion of the compensation housing 1 is at2. It is guaranteed that the molded lens 2 one (Δf1+Δf2)+the molded lens 2 two (Δf1+Δf2)=ΔT*L*at1+ΔT*L*at2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com