Construction method of converter device IGBT residual service life prediction model

A technology of life prediction model and variable flow device, which is applied in the direction of neural learning method, biological neural network model, neural architecture, etc., can solve the problems of poor generalization and doubts in the generalization ability of the model, and achieve strong generalization , Avoid major operational accidents, improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

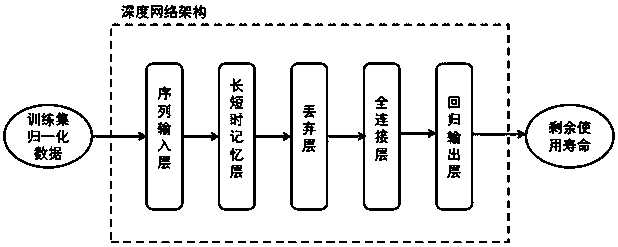

[0030] The construction method of the remaining service life prediction model of the IGBT of the converter device is realized by the following steps:

[0031] Step 1. Collect IGBT accelerated aging data

[0032] On the high and low temperature standard test bench, change the IGBT within the test temperature range, from the minimum temperature to the maximum temperature as a cycle (according to the test standard: minimum temperature T min= -40℃; maximum temperature T max =125℃), the period of each cycle is the same (the period of each cycle is 4 hours); a set of characteristic parameter data sets are collected after each cycle: emitter-collector saturation voltage drop V ce(sat) , gate-emitter threshold voltage V GE(th) , collector current I CE(on) , diode conduction voltage drop V f , gate saturation current IG(sat) and thermal impedance Z th ; Multiple cycles until all the characteristic parameters in the characteristic parameter data set reach the degradation judgment t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com