Unshielded twisted pair cable and preparation method thereof

A twisted pair and unshielded technology, applied in the field of unshielded twisted pair cables and their preparation, can solve the problems of difficulty in obtaining high flame retardant properties and high mechanical properties of cable materials, small cable transmission capacity, large corona loss, etc. , to increase anti-ultraviolet and anti-aging properties, reduce corona loss, improve flame retardant properties and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A kind of preparation method of unshielded twisted pair cable, comprises the following steps:

[0032] S1. Wire drawing: select copper material, use a wire drawing machine to make core wire conductors, and wrap the outer insulation layer of each single wire conductor;

[0033] S2. Twisting: Two core wires are a set of twisted wire pairs, which are twisted together in a twisted structure;

[0034] S3. Cabling: Use a pre-twisting cable machine to form a cable, and the untwisting rate is controlled at 15-25%;

[0035] S4. Sheath: Mix the glass fiber, elastomer, carbon black, polyphosphazene, and antioxidant according to the mass and fraction ratio, mechanically stir to obtain a mixture, extrude and pelletize the mixture to obtain a sheath Cover; wrap a layer of sheath on the outside of the cable; protect the cable.

[0036] S5. Packaging: Using network analyzers, all products are packaged out of the warehouse after strict high-frequency and low-frequency tests.

Embodiment 1

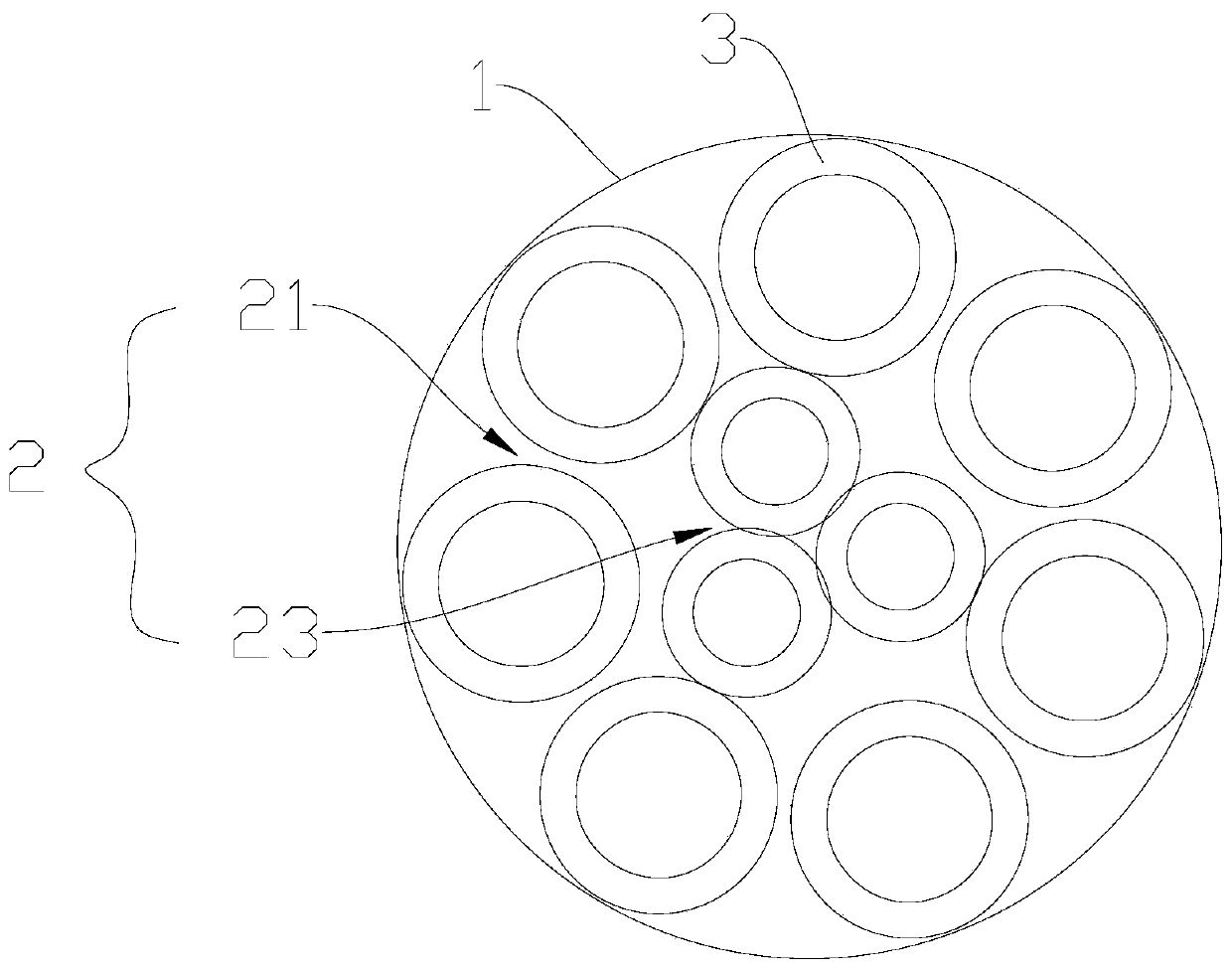

[0038] This embodiment provides an unshielded twisted-pair 3 cable, including a twisted-pair layer 2 and a sheath 1 covering the twisted-pair layer 2. The twisted-pair layer 2 includes two layers arranged sequentially from the inside to the outside. Protective layer, the inner protective layer 23 is formed in a circle by 3 twisted pairs 3, and the outer protective layer 21 is formed in a circle by 7 twisted pairs 3; from the inner protective layer 23 to the outer layer In the direction of the protective layer 21, the diameter of the twisted pair 3 gradually increases, wherein the gradient of the diameter of the twisted pair 3 in the protective layer is 0.1mm, and the minimum diameter of the twisted pair 3 in the innermost protective layer is 0.1mm .

[0039] The sheath 1 includes the following components: 35 parts of glass fiber, 8 parts of SBS, 18 parts of carbon black, 4 parts of polyphosphazene, and 3 parts of antioxidant.

[0040] This embodiment also provides a method fo...

Embodiment 2

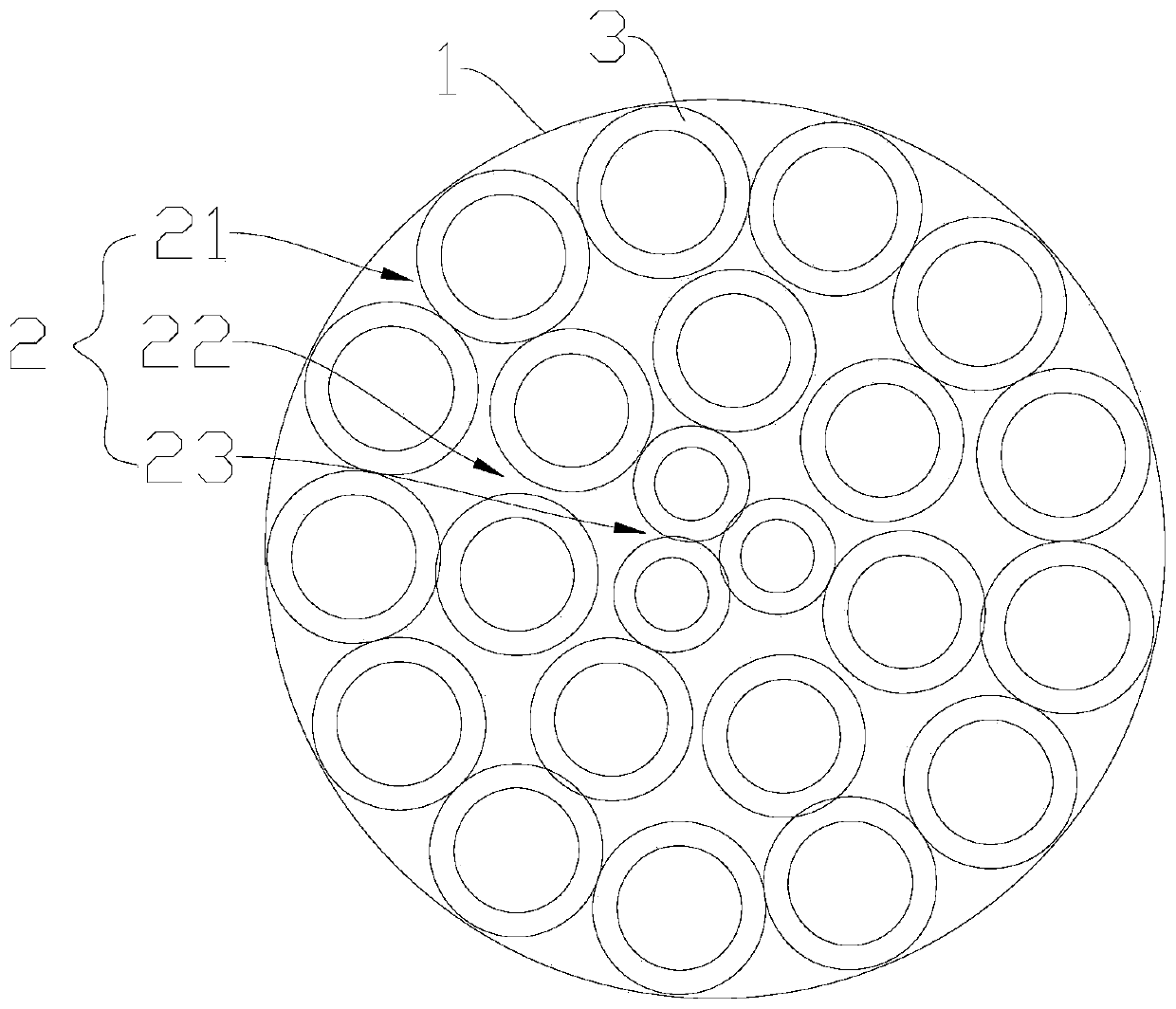

[0043] This embodiment provides an unshielded twisted-pair 3 cable, including a twisted-pair layer 2 and a sheath 1 covering the twisted-pair layer 2. The twisted-pair layer 2 includes two layers arranged sequentially from the inside to the outside. Protective layer, the inner protective layer 23 is formed in a circle by 3 twisted pairs 3, and the outer protective layer 21 is formed in a circle by 7 twisted pairs 3; from the inner protective layer 23 to the outer layer In the direction of the protective layer 21, the diameter of the twisted pair 3 gradually increases, wherein the gradient of the diameter of the twisted pair 3 in the protective layer is 0.2mm, and the minimum diameter of the twisted pair 3 in the innermost protective layer is 0.2mm .

[0044] The cable sheath 1 includes the following components: 17 parts of glass fiber, 5 parts of SBS, 15 parts of carbon black, 1 part of polyphosphazene, and 1 part of antioxidant.

[0045] This embodiment also provides a metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Minimum diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap