Light emitting diode and driving method thereof, light source device and electronic equipment

A technology of light-emitting diodes and light-emitting layers, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of large spectral half-height width and low color purity of color light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

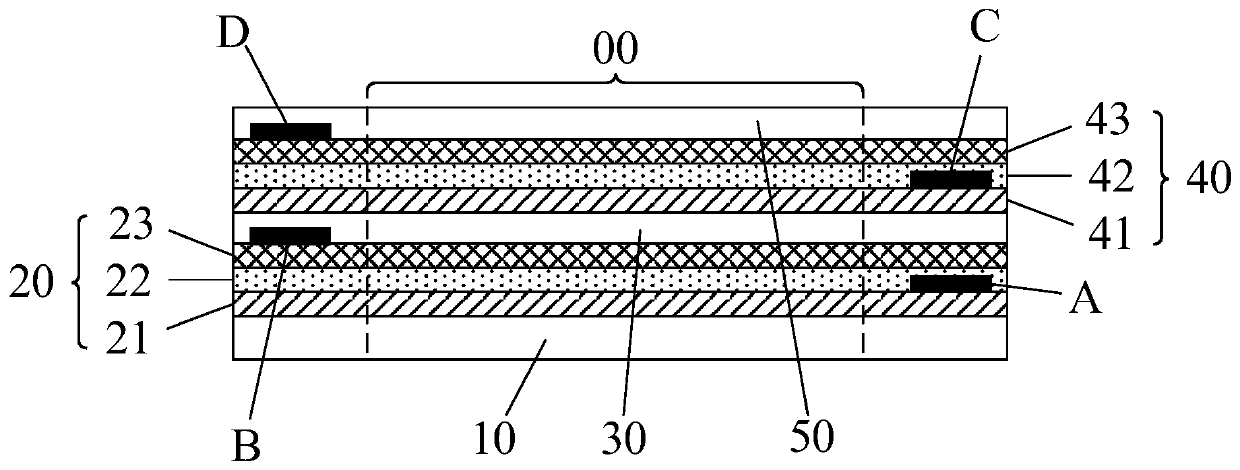

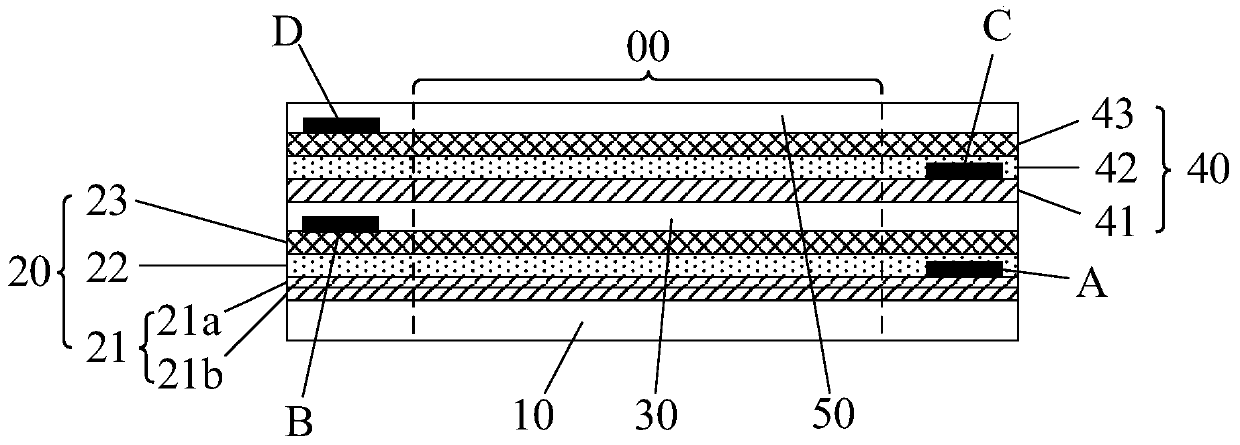

[0056] figure 1 A schematic cross-sectional view of a light-emitting diode according to Embodiment 1 of the present invention is shown, referring to figure 1 , the LED consists of:

[0057] Substrate 10;

[0058] A reflective luminescent layer 20, disposed on the substrate 10;

[0059] The first electrode A, the second electrode B and the first insulating layer 30 are separately arranged on the reflective light-emitting layer 20;

[0060] a saturable absorber layer 40, disposed on the first insulating layer 30;

[0061]The third electrode C, the fourth electrode D and the reflective composite layer 50 are separately arranged on the saturable absorber layer 40, and the reflectivity of the reflective luminescent layer 20 is greater than the reflectivity of the reflective composite layer 50;

[0062] Wherein, the orthographic projections of the saturable absorber layer 40 , the third electrode C, the fourth electrode D and the reflective composite layer 50 on the reflective l...

Embodiment 2

[0112] The embodiment of the present invention also discloses a driving method, which can be used to drive the above-mentioned light-emitting diodes, and the driving method includes:

[0113] The first positive voltage is input to the first electrode A, and the first negative voltage is input to the second electrode B.

[0114] Wherein, the first electrode A can be used as the anode for controlling the reflective luminescent layer 20, and the second electrode B can be used as the cathode for controlling the reflective luminescent layer 20, that is, in the embodiment of the present invention, the forward bias can be input to the reflective luminescent layer 20. pressure, thereby driving the reflective light-emitting layer 20 to emit light.

[0115] Optionally, the method also includes:

[0116] A second negative voltage is input to the third electrode C, and a second positive voltage is input to the fourth electrode D.

[0117] Wherein, the third electrode C can be used as th...

Embodiment 3

[0124] The embodiment of the present invention also discloses a light source device, including the above light emitting diode.

[0125] Wherein, in the field of display, the light source device may specifically be a backlight module, and the embodiment of the present invention does not specifically limit the light source device.

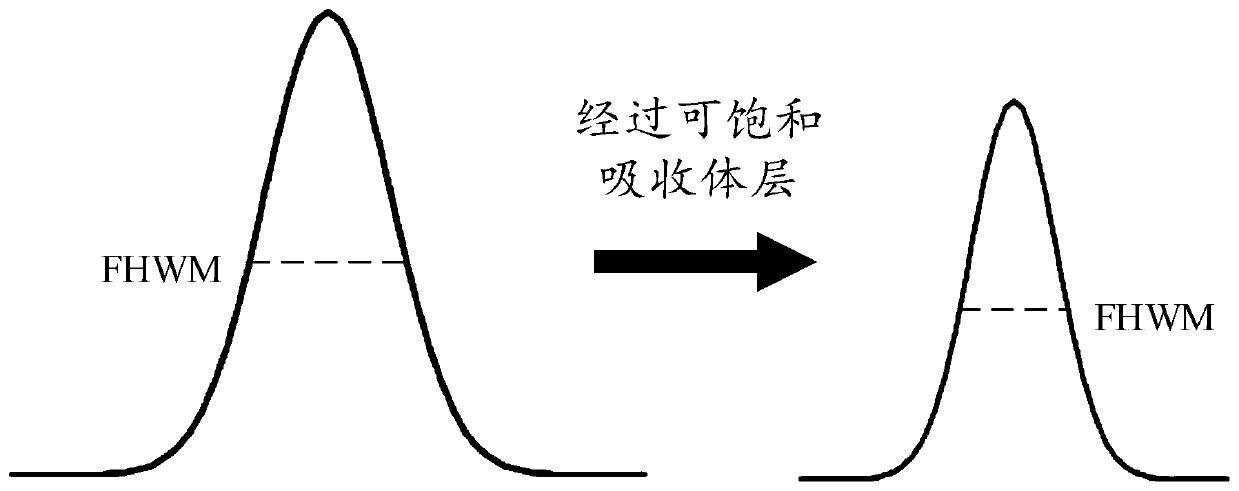

[0126] In an embodiment of the present invention, the light-emitting diode in the light source device includes a substrate, a reflective light-emitting layer disposed on the substrate, a first electrode, a second electrode, and a first insulating layer separately disposed on the reflective light-emitting layer, and are disposed on A saturable absorber layer on the first insulating layer, and a third electrode, a fourth electrode and a reflective composite layer separately arranged on the saturable absorber layer. Wherein, the reflectivity of the reflective luminescent layer is greater than that of the reflective composite layer, so as to ensure that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com