Soil remediation device for treating heavy metal pollutants

A soil remediation and pollutant technology, which is applied in the field of heavy metal soil remediation, can solve the problems of uneven irrigation and small one-time irrigation area of a single vehicle, and achieve the effect of uniform irrigation and increase of irrigation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

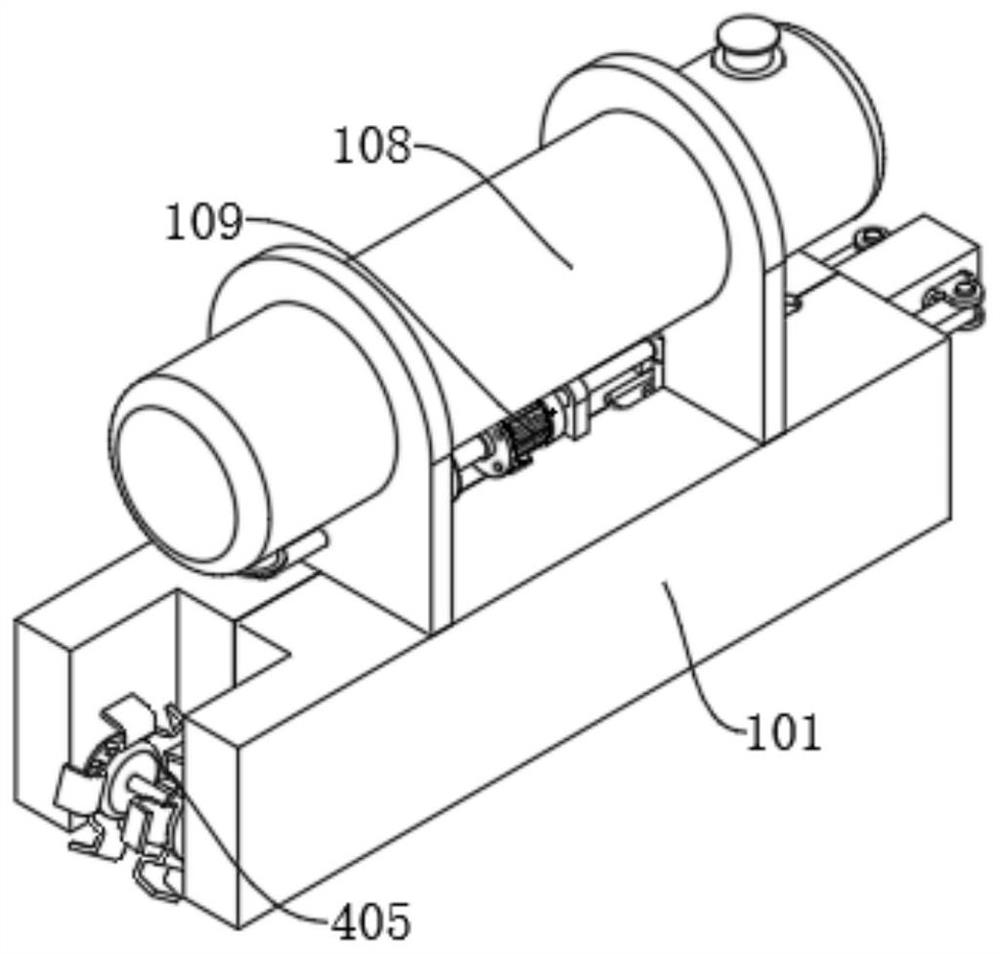

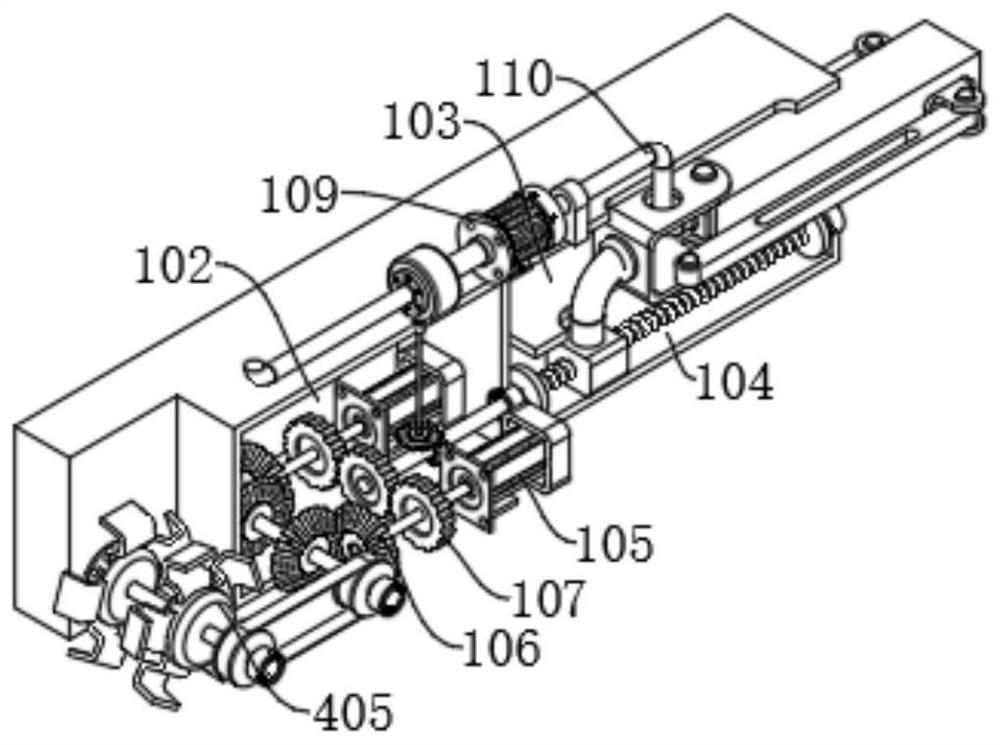

[0028] A soil remediation device for treating heavy metal pollutants, comprising: a main body frame 101, an assembly bin 102, an unfolding bin 103, and a driving bin 104, the left side of the main frame 101 is provided with the assembly bin 102, and the upper part of the right side of the main frame 101 is provided with an unfolding bin 103, the lower part of the right side of the main frame 101 is provided with a driving compartment 104, the water supply tank 108 is fixedly installed above the main frame 101, and two sets of servo motors 105 are fixedly installed on the front and rear sides of the inner side of the assembly compartment 102, and the servo motor 105 is mounted on the main shaft from From left to right, a rotating helical gear 106 and a rotating ratchet 107 are fixedly installed in sequence. The left end of the driving mechanism is meshed with the inner side of the rotating ratchet 107, and the left side of the driving mechanism is meshed with the lower side of th...

Embodiment 2

[0030] Embodiment 2: Based on Embodiment 1, the difference is:

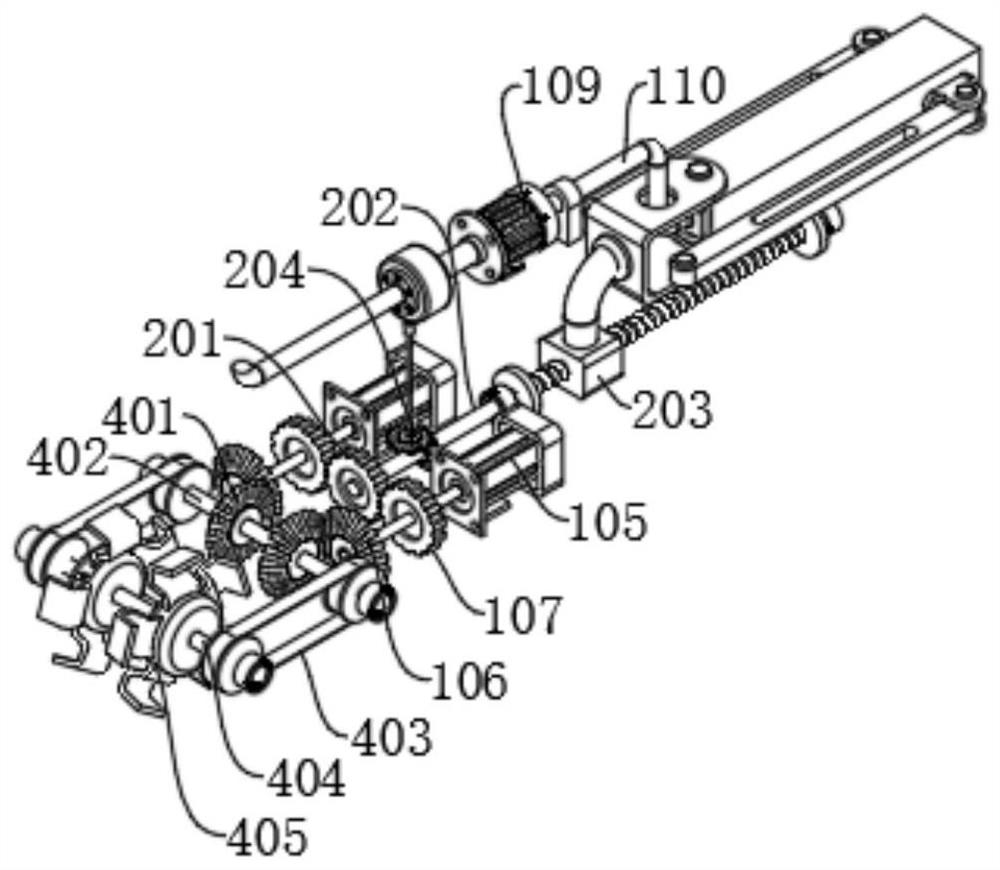

[0031] The drive mechanism includes: a rotating gear 201, a rotating screw mandrel 202, a moving block 203 and a lower helical gear 204. The inner side of the rotating ratchet 107 is meshed with the front and rear sides of the rotating gear 201, and the axis of the rotating gear 201 is connected to the left end of the rotating screw rod 202. Fixedly connected, the left side of the rotating screw rod 202 is fixedly connected with the axis of the lower helical gear 204, the upper side of the lower helical gear 204 is meshed with the lower side of the water supply valve mechanism, and the upper side of the rotating screw rod 202 is threaded with a moving block 203. The upper side of the block 203 is fixedly connected with the lower side of the left end of the irrigation mechanism.

[0032] The irrigation mechanism includes: a fixed U-shaped block 301, a moving rod 302, an integrated block 303, a front rotating block...

Embodiment 3

[0036] Embodiment 3: Based on Embodiment 1 and 2, but the difference is:

[0037] The excavation mechanism includes: transmission helical gear 401, transmission shaft 402, transmission wheel set 403, rotation shaft 404 and excavation runner 405, the inner side of the rotation helical gear 106 is meshed with two sets of transmission helical gears 401, and the transmission helical gear 401 shaft center is fixedly connected with the front and rear sides of the transmission shaft 402 middle part, the front and rear ends of the transmission shaft 402 are fixedly connected with the shaft center of the right end of the transmission wheel group 403, the left end shaft center of the transmission wheel group 403 is fixedly connected with the front and rear ends of the rotation shaft 404, and the rotation shaft The front and rear sides of the middle part of the 404 are fixedly connected with the excavation runner 405 axis, and the front and rear ends of the transmission shaft 402 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com