Sole adhesion method

An adhesive and shoe technology, which is applied in the field of sole adhesion through vacuum sealing bags, can solve the problems of reducing production costs, deformation of soles and shoe edges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In the following, with the accompanying drawings and preferred embodiments of the present invention, the technical means adopted by the present invention to achieve the intended purpose of the invention are further described.

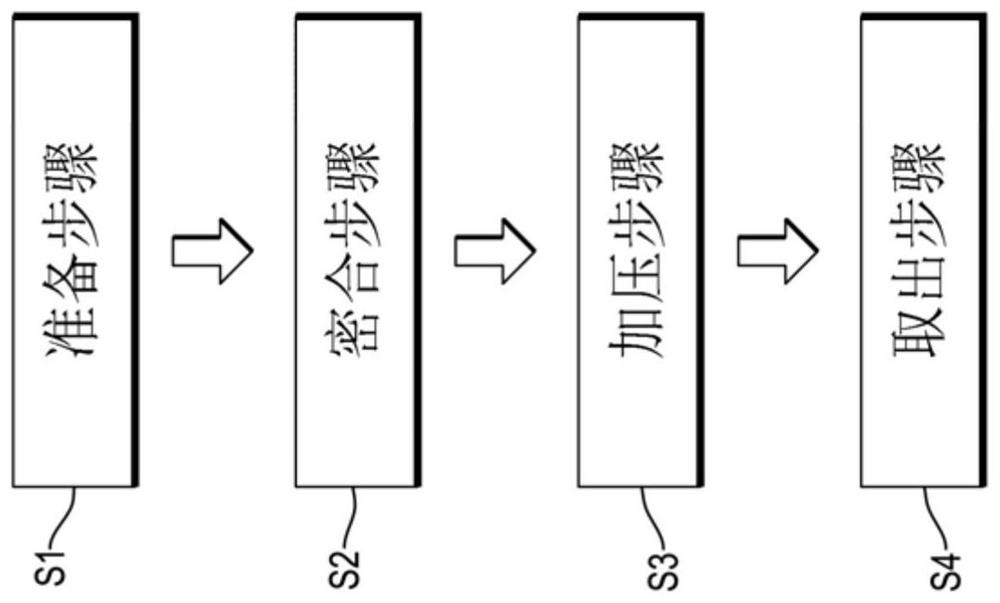

[0036] The present invention is a method for adhering soles, and the preferred embodiments of the present invention are figure 1 As shown, the sole adhesion method includes a preparation step S1, a close-fitting step S2, a pressurizing step S3, and a removing step S4, wherein:

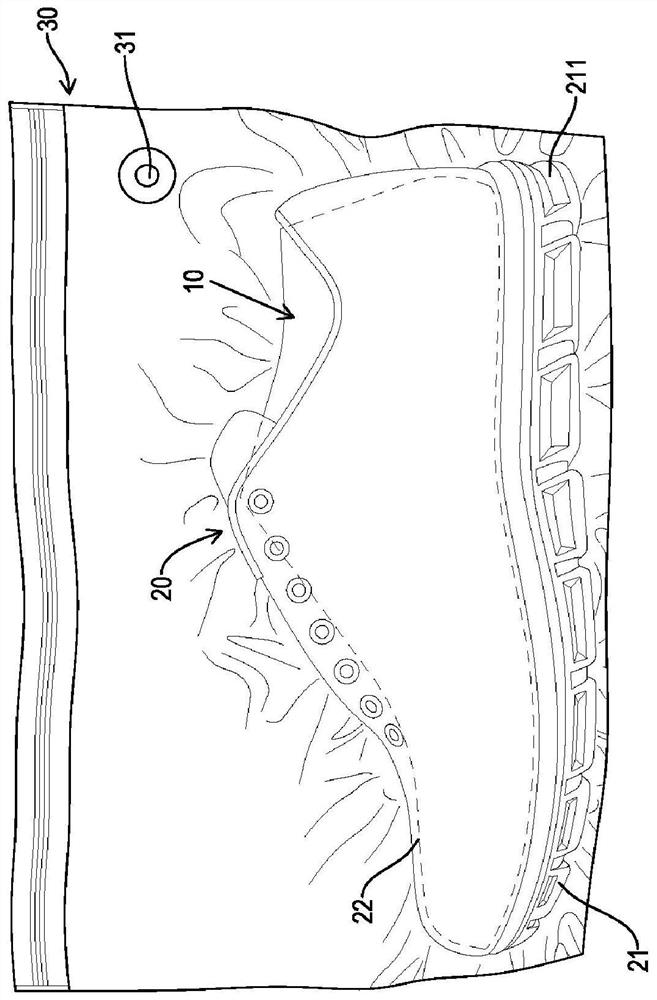

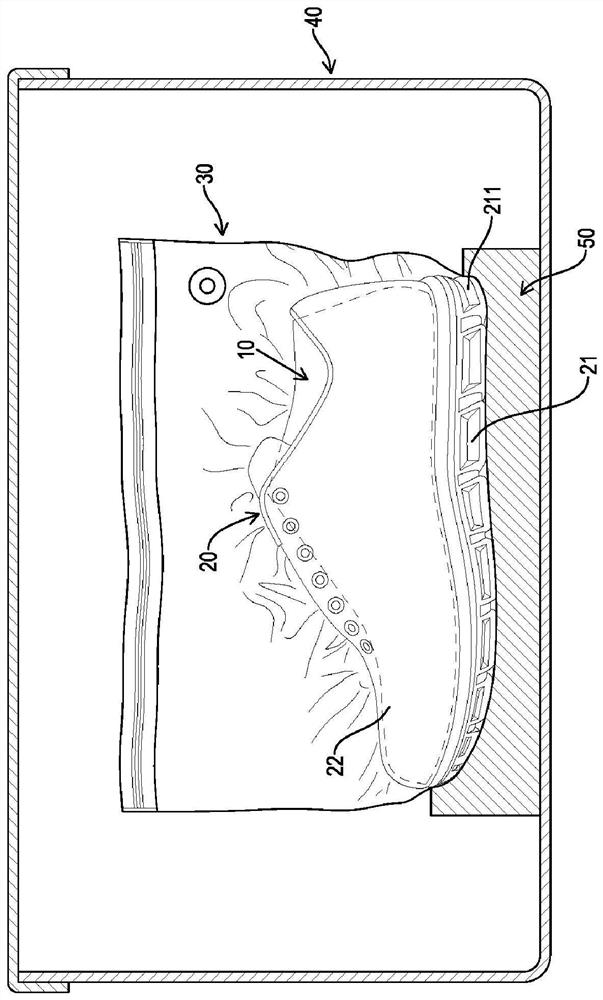

[0037] Preparation step S1: first put the shoe last 10 into the semi-finished shoe formed by combining the upper 22 and the midsole, heat the bottom surface of the semi-finished shoe and the glue coated on the sole 21, and then combine the semi-finished shoe with the sole 21 through the glue The shoe 20 is formed; the glue used in this step can be water glue or hot melt glue. When the glue is water glue, the water glue can be applied to the bottom surface of the semi-finished s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com