Intelligent liquid temperature and flow double-control mixer

A liquid temperature, dual control technology, used in mixers, mixers with rotary stirring devices, chemical instruments and methods, etc., can solve environmental changes, manual control of inaccurate temperature and flow changes, cold and hot water mixers It takes a long time, it is difficult to meet the actual needs and other problems, to achieve the effect of compact structure, strong anti-interference ability and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the present invention, the present invention will be further clearly and completely described below in conjunction with reference to the accompanying drawings and in conjunction with embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

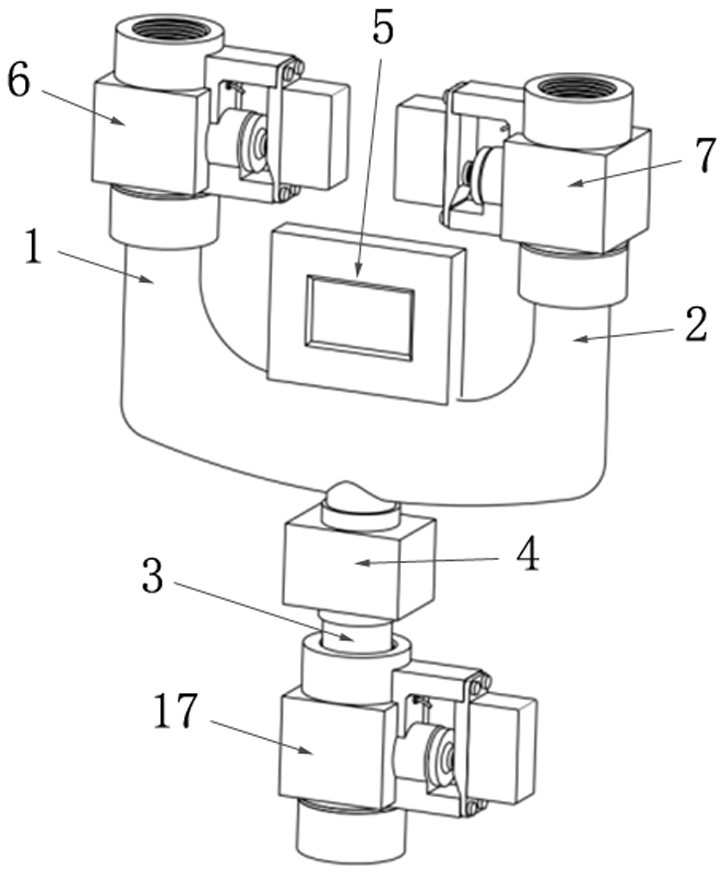

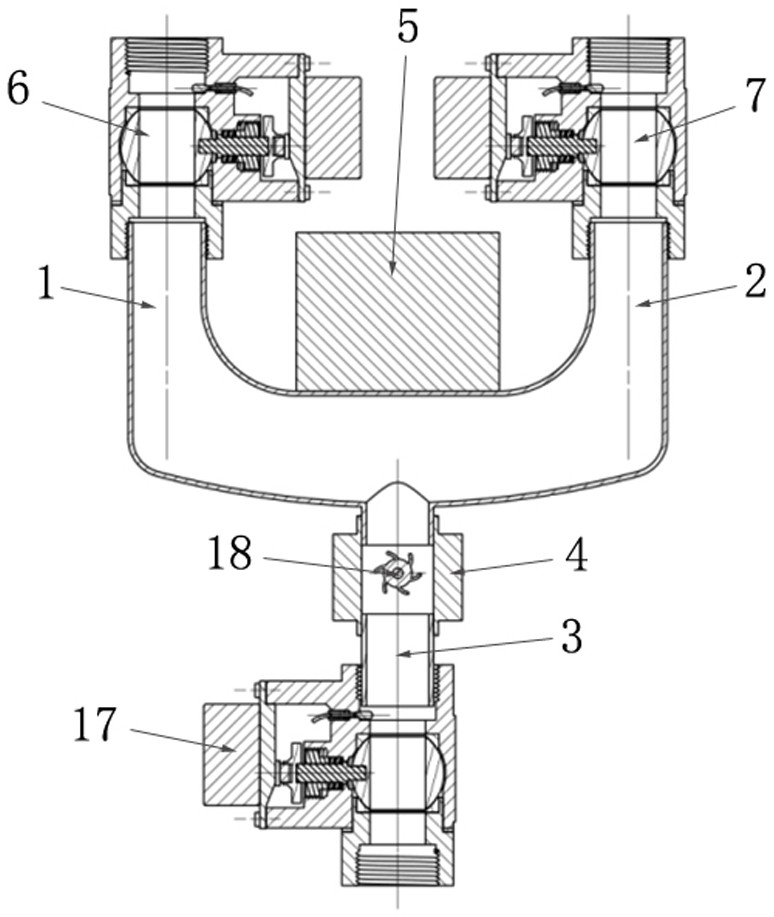

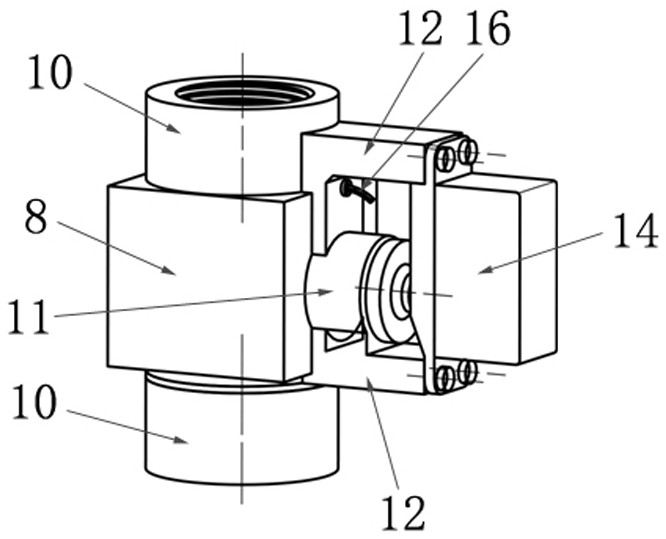

[0023] Such as Figure 1 to Figure 4 As shown, an intelligent liquid temperature and flow dual-control mixer includes a high-temperature liquid pipeline 1 , a low-temperature liquid pipeline 2 , a mixing liquid pipeline 3 , a mixing agitator 4 and a control circuit module 5 .

[0024] The bottom of the high-temperature liquid pipeline 1 and the bottom of the low-temperature liquid pipeline 2 are connected through a communication pipeline, and a liquid outlet is arranged on the communication pipeline, and the liquid outlet is connected to the input en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com