Device for solidifying fly ash and control system and control method

A technology for fly ash and power system, applied in sequence/logic controller program control, chemical instruments and methods, electrical program control, etc. Qualified and other problems to achieve the effect of solving the uneven distribution of heavy metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

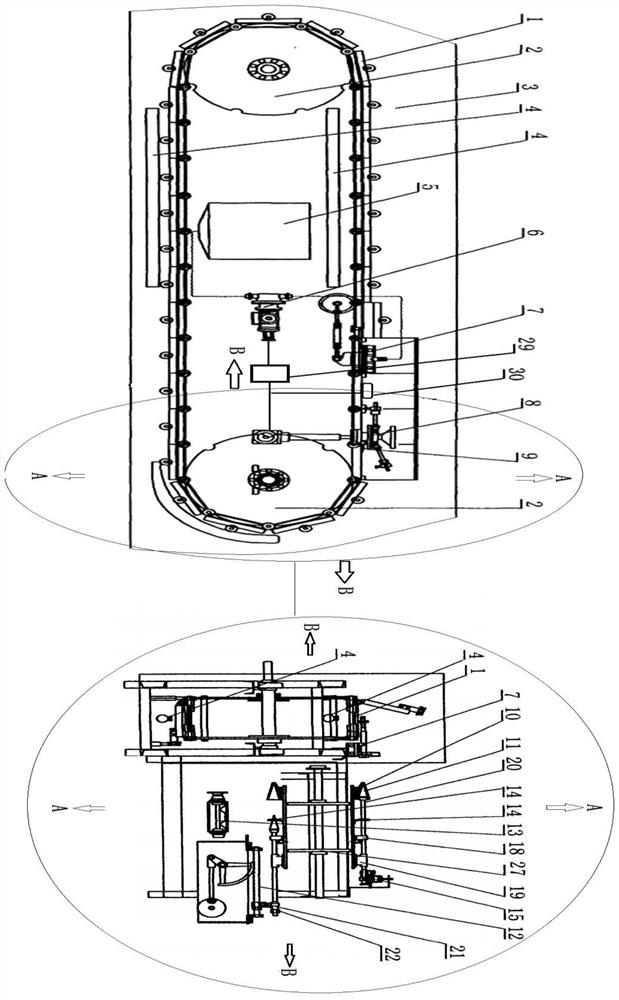

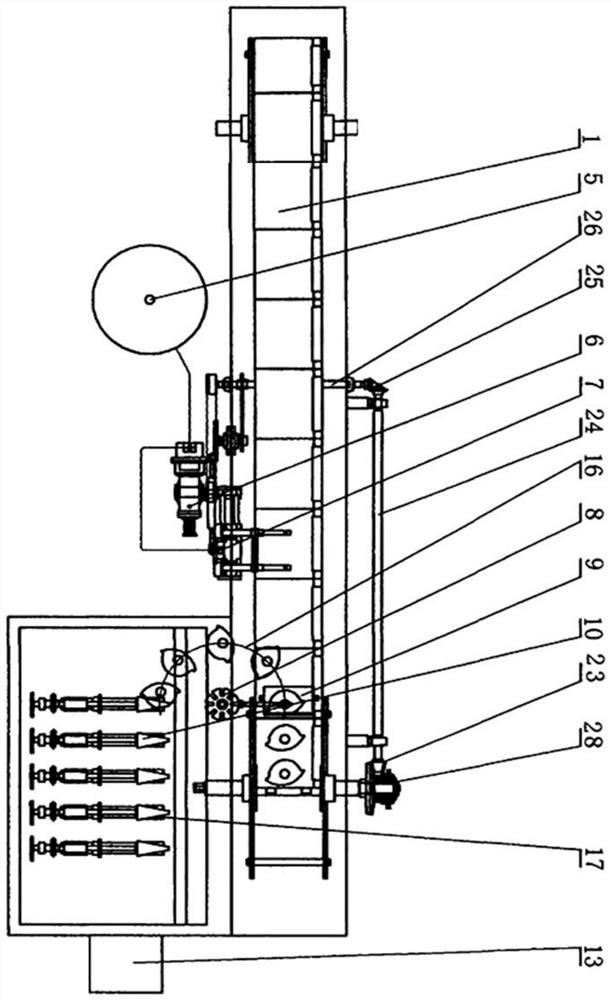

[0024] In specific implementation, such as Figure 1-2As shown, the device embodiment of the present application includes a transmission power system, an electric heating system, a mud roll forming system for forming the fly ash liquid mixture, and an electromechanical control system; wherein the transmission power system is placed by the water-ash mixed sludge connected by pipelines Cylinder 5, mud mixing conveying pump assembly 6 and conveying mud spraying pipe 7; electric heating system is composed of transmission node 1 mechanically connected with each other, transmission power runner 2, closed shell 3, forming electric heating plate 4; mud sheet The roll forming system consists of a mechanically connected cutting part 9, a roll forming roll control assembly 8, a screening channel 16, a mud sheet roll forming assembly 10, a tapered end 11, a movable adjustment part 12, ash solid block separation equipment 14, The ash solid block output device 13 is composed of; the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com