Synchronous dust-proof device utilizing machining kinetic energy

A dust-proof device and synchronous technology, applied in the attachments of sawing machines, metal processing equipment, manufacturing tools, etc., can solve the problems of a large amount of dust and cutting waste, the moment kinetic energy is not directly utilized, and endangers the physical and mental health of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

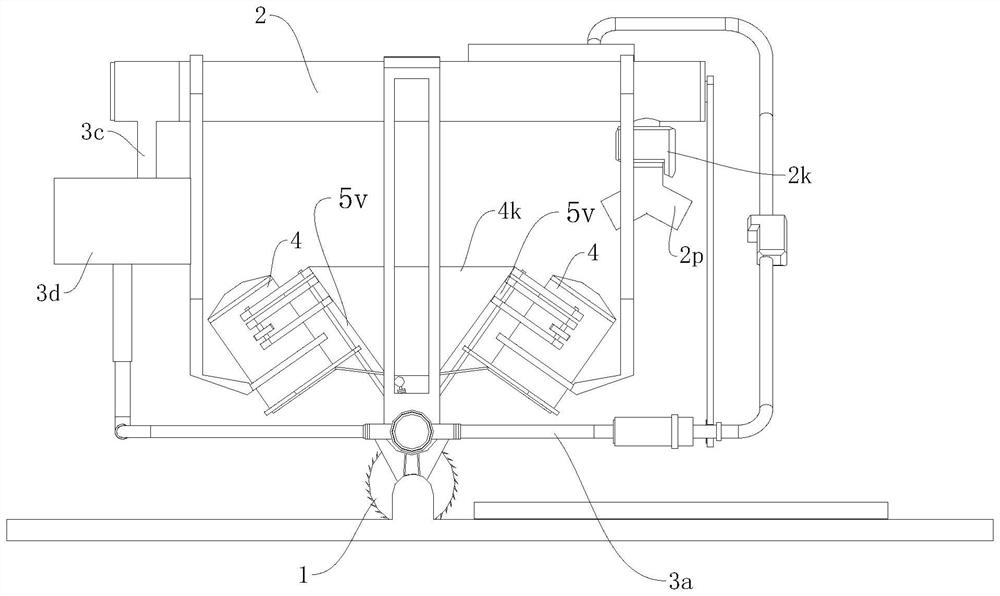

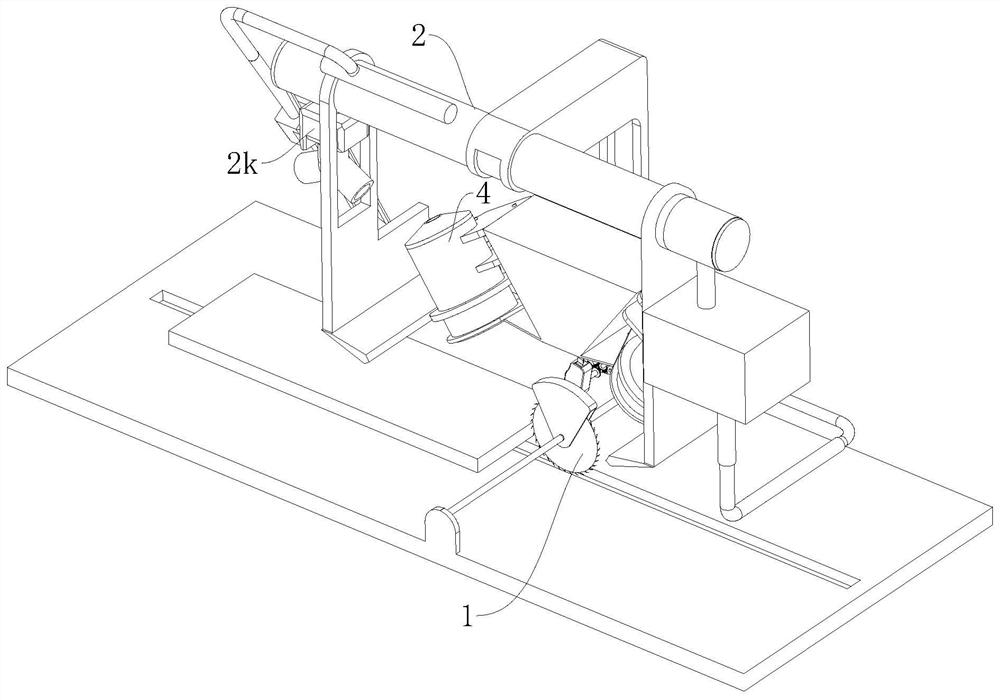

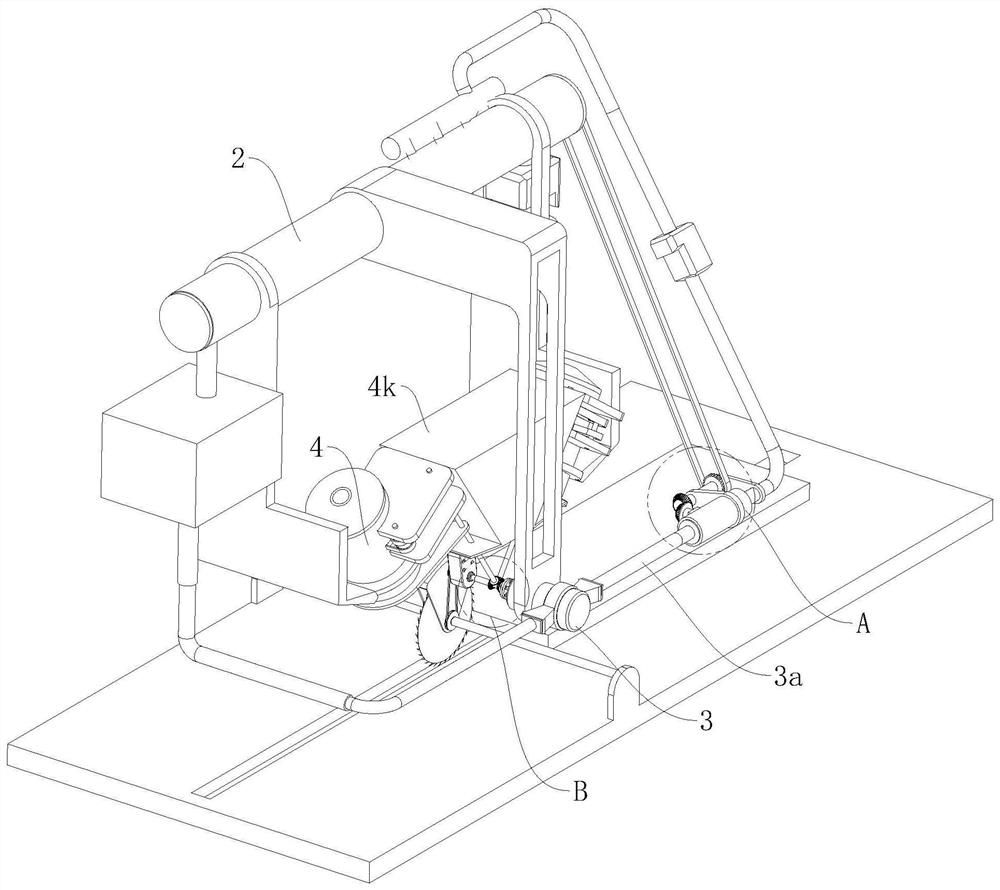

[0035] refer to Figure 1 to Figure 12 A synchronous dust-proof device using processing kinetic energy is shown, including a cutting saw blade 1, the dust-proof device includes a small reduction box 1a, a purification mechanism, a water pump 3 and a dust suction tube 4, and the input end of the small reduction box 1a passes through a transmission The chain 1b is transmission-connected with the axis of the cutting saw blade 1, and it is also located above the cutting saw blade 1. There are at least two dust suction cylinders 4, and the two are arranged symmetrically above the cutting saw blade 1. , each vacuum tube 4 is provided with a set of negative pressure fans 4a, the output end of the small reduction box 1a is connected to the negative pressure fans 4a in the two vacuum tubes 4 through the energy guide mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com