Special sampling manipulator for industrial robot

A technology of industrial robots and manipulators, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as low efficiency, small working range of manipulators, and inability to adjust mechanical fingers, etc., to achieve improved stability, wide application range, and reduced slippage The effect of the probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Further detailed explanation through specific implementation mode below:

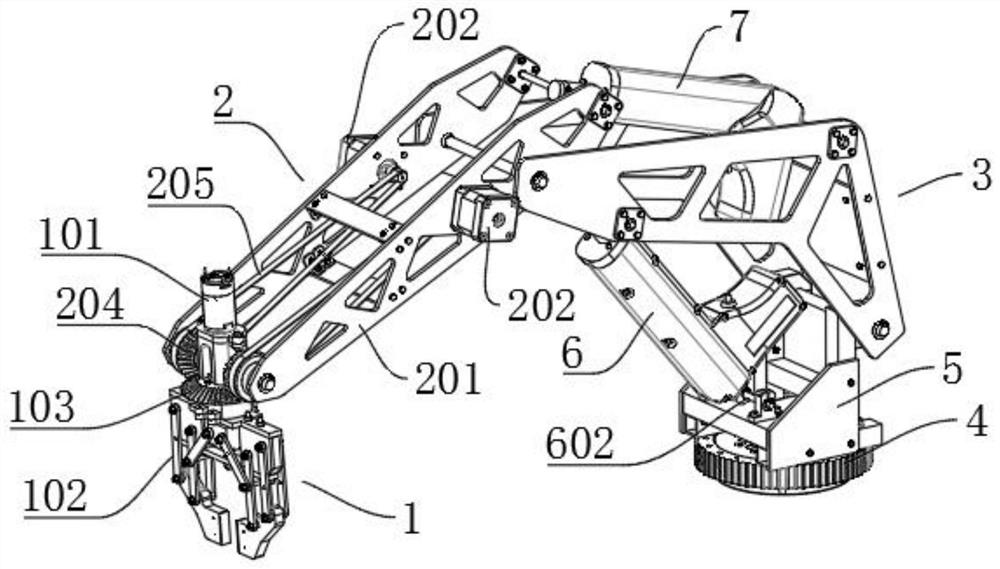

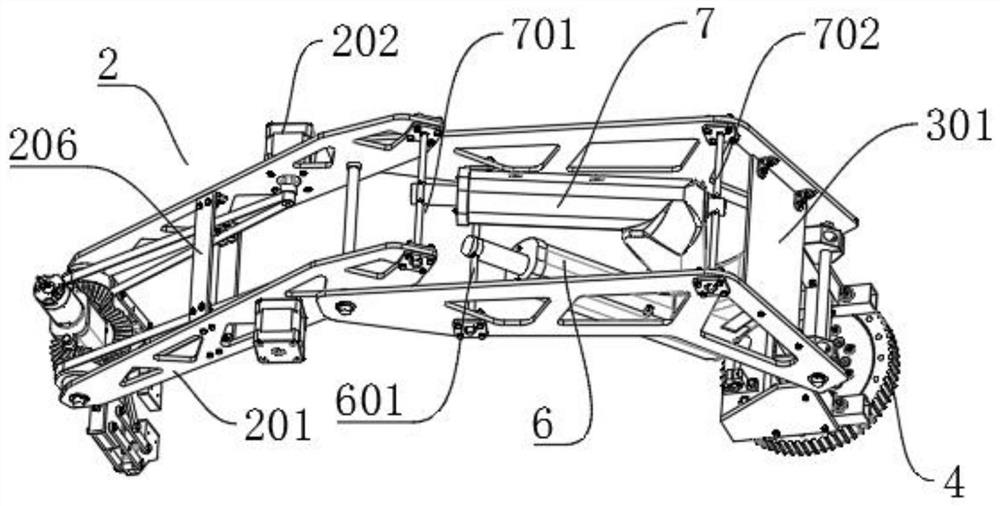

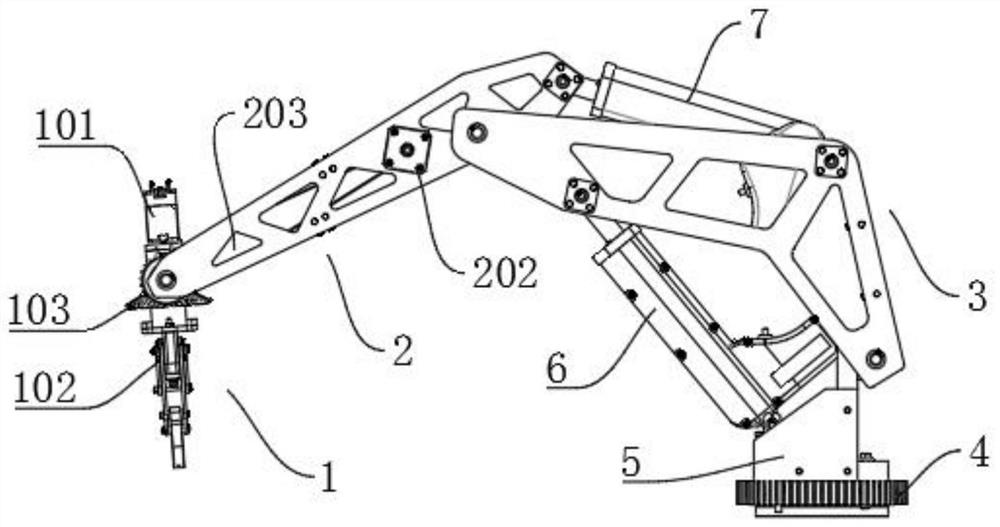

[0038] Such as Figure 1 to Figure 6 As shown, a special sampling manipulator for an industrial robot includes a manipulator part 1, a first articulated arm 2, a second articulated arm 3 and a second hydraulic cylinder 7, the left end of the first articulated arm 2 is movably connected to the manipulator part 1, and the The other end of the first articulated arm 2 is movably connected to the second articulated arm 3, one end of the second hydraulic cylinder 7 is movably connected to the rear end of the first articulated arm 2, and the other end of the second hydraulic cylinder 7 is connected to the second articulated arm 3 The middle portion; also includes a first hydraulic cylinder 6 and a fixed bracket 5, the upper end of the fixed bracket 5 is connected to the second articulated arm 3 and the first hydraulic cylinder 6, and the other end of the first hydraulic cylinder 6 is movably connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com