Laser plate making method and equipment

A laser and equipment technology, applied in the field of laser plate making method and its equipment, can solve the problems of increasing processing procedures, waste of resources, butt offset of plate film or steel wire mesh, etc., and achieve the effect of reducing waste of resources and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

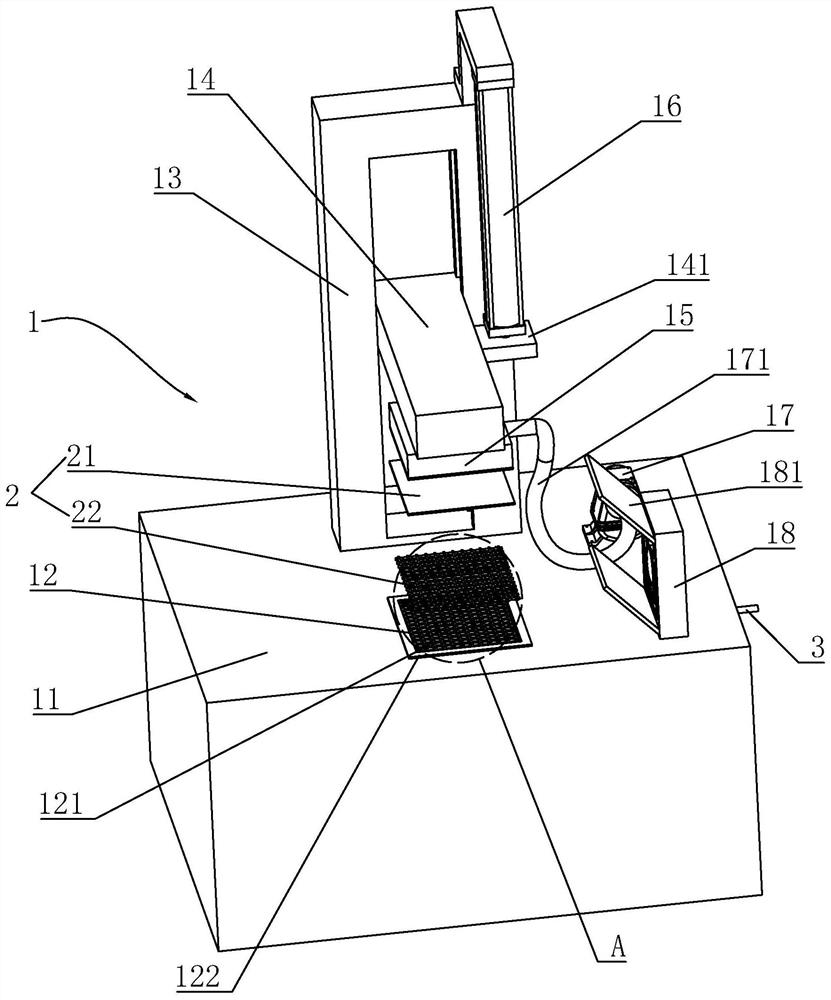

[0040] refer to figure 1 , is a kind of laser plate-making method disclosed in the present invention, comprises the following operation steps:

[0041]Bonding of the stencil film and the steel wire mesh: the stencil film 21 and the steel mesh 22 are bonded and fixed by the gluing and bonding integrated device 1 to obtain the screen plate 2;

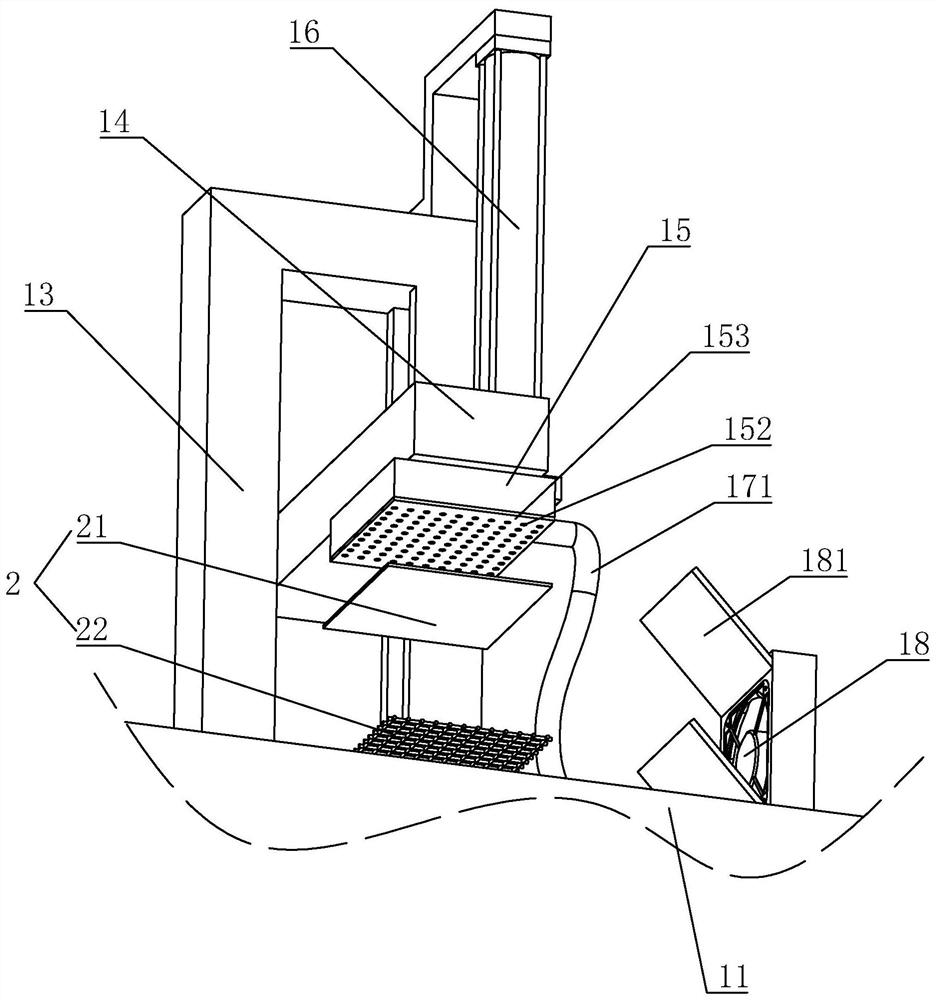

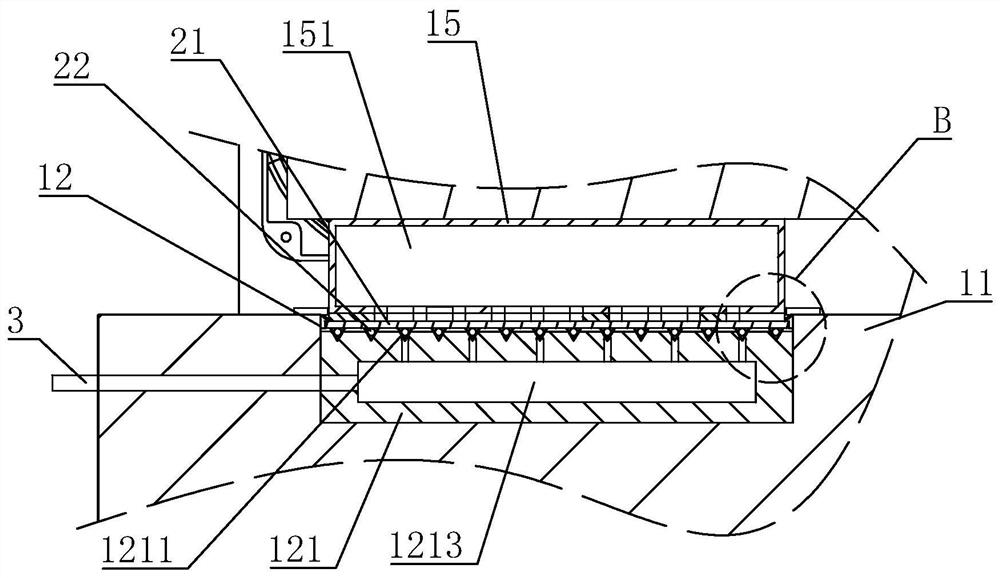

[0042] refer to figure 1 , the gluing and bonding integrated device 1 used in the bonding operation steps of the plate film 21 and the steel wire mesh 22 includes a workbench 11, a support block 13 is bonded to the workbench 11, and the support block 13 is arranged along the vertical direction, Vertical sliding is provided with connecting rod 14 on the support block 13, and the support block 13 is provided with the cylinder 16 that drives the connecting rod 14 to move along the vertical direction of the support block 13. The telescopic rod of the cylinder 16 is arranged towards the connecting rod 14. In this embodiment, one side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com