Pod propeller capable of generating vertical force

A thruster and vertical force technology, which is applied in ship propulsion, propulsion components, outboard propulsion devices, etc., can solve problems such as the inability to improve the stability of ships, and achieve the effects of high angle adjustment efficiency, flexible operation, and simple and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

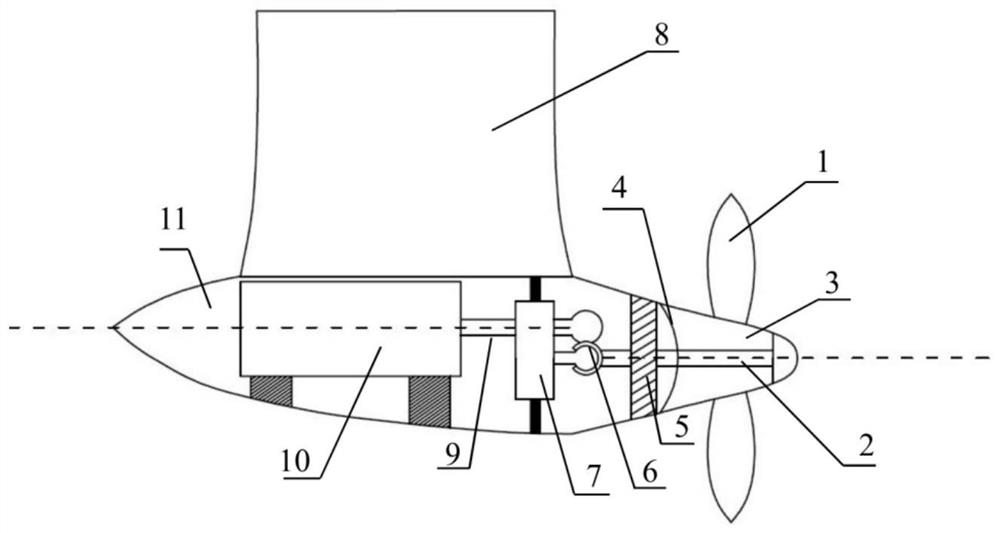

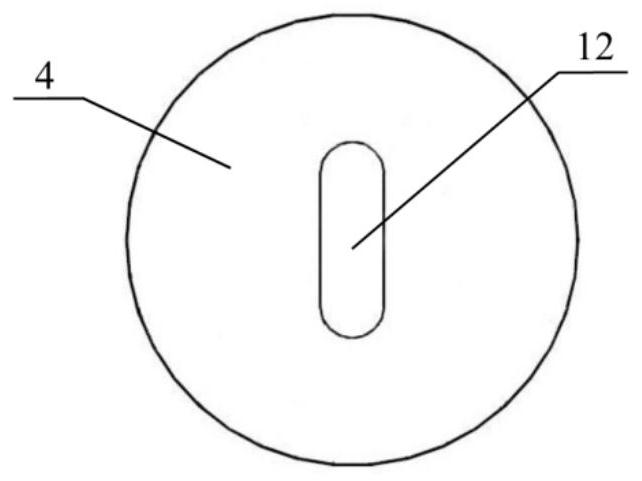

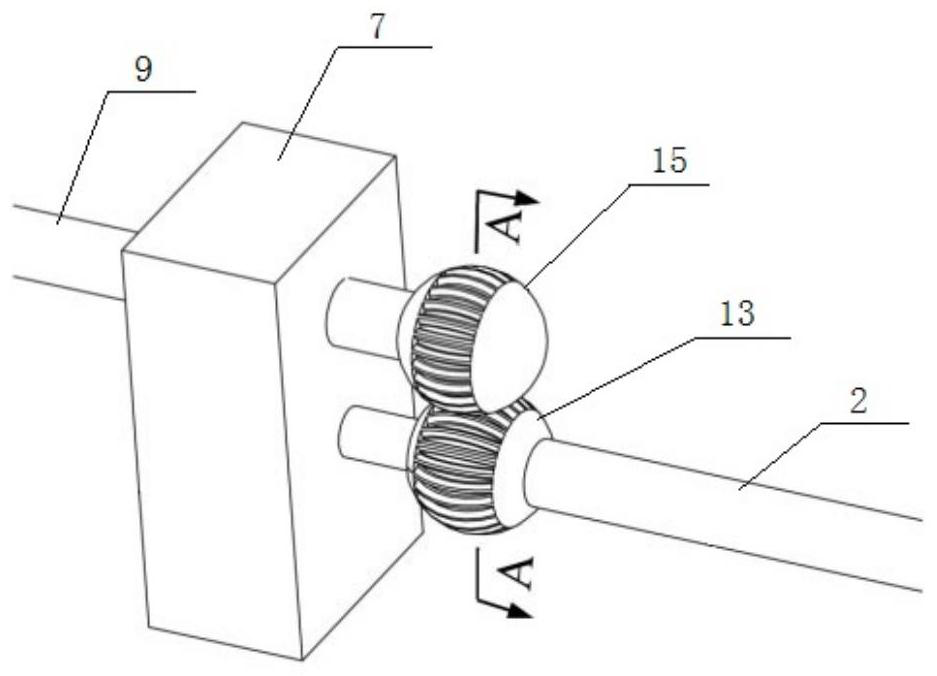

[0032] Such as Figure 1 to Figure 16 As shown, a pod propeller that can generate vertical force includes a pod body 11 and a propeller, the propeller includes a propeller shaft 2, a propeller hub 3 and blades 1, and the propeller hub 3 is driven by the propeller shaft 2 Rotate, and then drive the blade 1 to rotate, the paddle shaft 2 passes through the end of the pod body 11, it is characterized in that: the pod body 11 is provided with a main shaft 9 and a motor 10 for driving the main shaft 9 to rotate, so The main shaft 9 is provided with a brake lock device 7, which plays a role in supporting and controlling the main shaft 9, and the brake lock device 7 adopts the existing brake structure, which will not be repeated here. A rotating center ball 14 is fixed inside the pod body 11, a first spherical gear 15 is provided on the main shaft 9, and a hollow second spherical gear 13 is provided at one end of the paddle shaft 2 inside the pod body 11. , the first spherical gear 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com