A kind of directional passive driving thin film and its preparation method

A directional passive and self-driven technology, applied in the manufacture of microstructure devices, instruments, fluid velocity measurement, etc., can solve problems such as complex process methods, and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Step 1: Deposit a layer of 50nm Ti thin film on the glass substrate by magnetron sputtering deposition process.

[0055] Step 2: Write the directional passive driving pattern on the 50nm metal Ti film by laser direct writing technology to obtain a patterned film. Among them, the writing parameters of the laser direct writing technology are: laser power 4mW; laser pulse width 1ms.

[0056] Step 3: immerse the obtained patterned thin film in 4.5% HF diluent for 20 minutes to obtain an oriented passive-driven thin film.

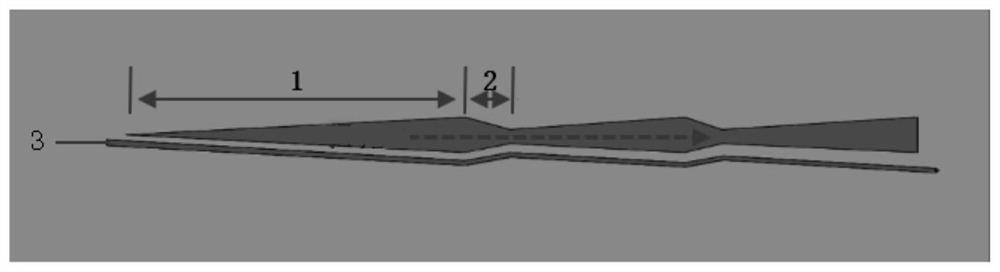

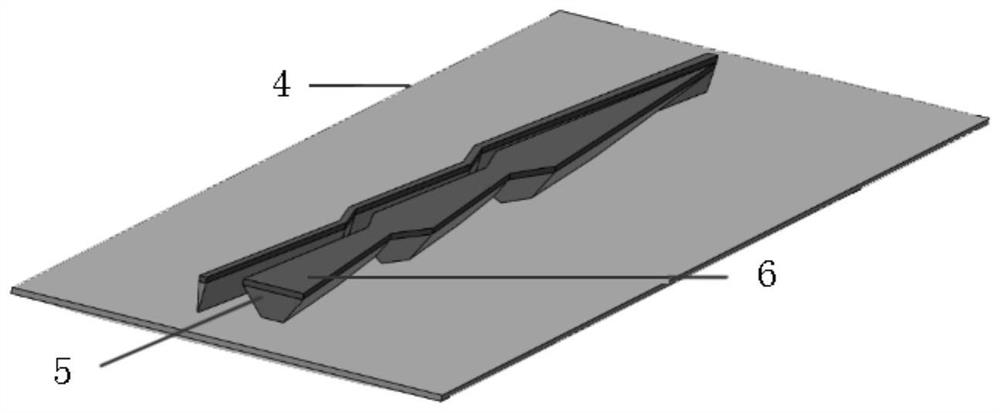

[0057] Step 4: When the water mist is sprayed onto the surface of the prepared directional passive source-driven film, the droplets can move along such as figure 1 Move in the direction indicated by the dotted arrow to realize long-distance transportation.

[0058] Experiments have found that a 50nm Ti film can be completely etched in about 15 minutes, and the TiO obtained by laser oxidation 2 Patterns are preserved. Since the HF diluent has an isotro...

Embodiment 2

[0060] Step 1: Deposit a layer of 200nm Ti thin film on the glass substrate by magnetron sputtering deposition process.

[0061] Step 2: Write the directional passive driving pattern on the 200nm metal Ti film by laser direct writing technology to obtain a patterned film. Among them, the writing parameters of the laser direct writing technology are: laser power 4mW; laser pulse width 1ms.

[0062] Step 3: immerse the obtained patterned thin film in 4.5% HF diluent for 100 min to obtain an oriented passive-driven thin film.

[0063] Step 4: When the water mist is sprayed onto the surface of the prepared directional passive source-driven film, the droplets can move along such as figure 1 Move in the direction indicated by the dotted arrow to realize long-distance transportation.

Embodiment 3

[0065] Step 1: Deposit a layer of 20nm Ti thin film on the glass substrate by magnetron sputtering deposition process.

[0066] Step 2: Write the directional passive driving pattern on the 20nm metal Ti film by laser direct writing technology to obtain a patterned film. Among them, the writing parameters of the laser direct writing technology are: laser power 4mW; laser pulse width 1ms.

[0067] Step 3: immerse the obtained patterned thin film in 4.5% HF diluent for 10 minutes to obtain an orientation passively driven thin film.

[0068] Step 4: When the water mist is sprayed onto the surface of the prepared directional passive source-driven film, the droplets can move along such as figure 1 Move in the direction indicated by the dotted arrow to realize long-distance transportation.

[0069] Compared with the anisotropic surface produced by chemical gradients in the prior art, which leads to slow movement speed and limited long-distance transport distance of droplets, the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com