Preparation method of large-area uniform single-layer graphene film

A technology of single-layer graphene and multi-layer graphene, which is applied in the field of graphene and can solve the problems of large-area, uniform, and high-quality single-layer graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1. Preparation of large-area continuous single-layer graphene film

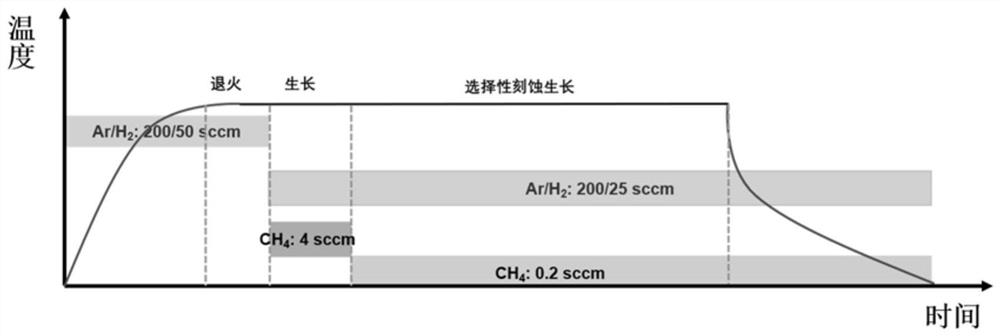

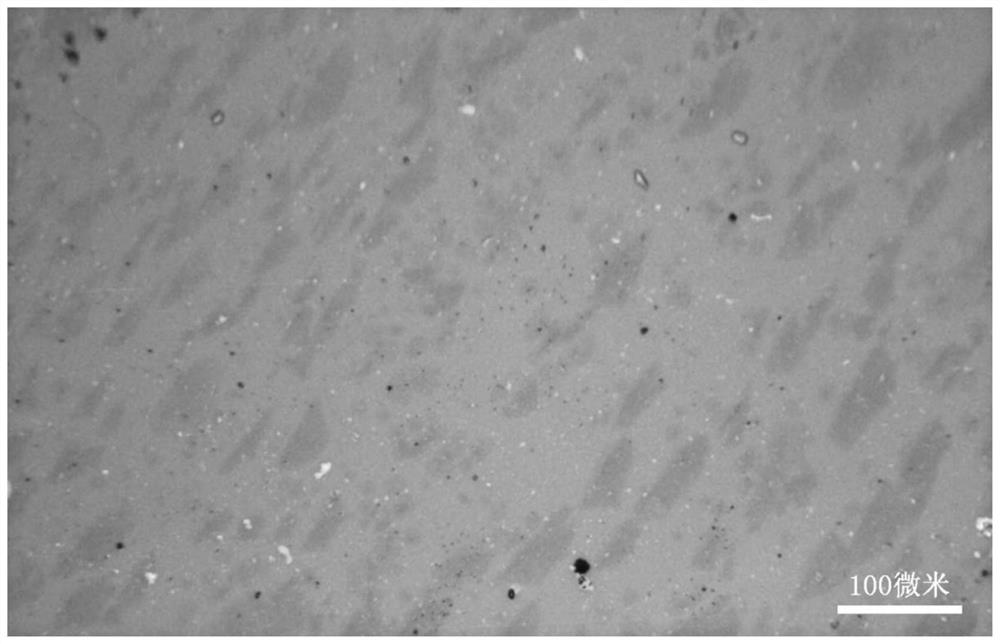

[0056] 1) Preparation of large-area monolayer continuous graphene films

[0057] The large-area single crystal copper (111) was electrochemically polished, the sample copper foil with a thickness of 100 μm was connected to the positive electrode of the DC power supply, and the metal copper electrode was connected to the negative electrode. The applied voltage is 2-6V, preferably 5V, the current is 1-4A, preferably 3A, and the polishing time is 2-5min, preferably 3min. Then rinse with deionized water, normal N 2 Blow dry. , placed in the center of the tube furnace, passed 200sccm of argon and 25sccm of hydrogen, set the heating time to 45min, when the temperature reached 1075 ℃, passed 4sccm of methane and grown for 1h.

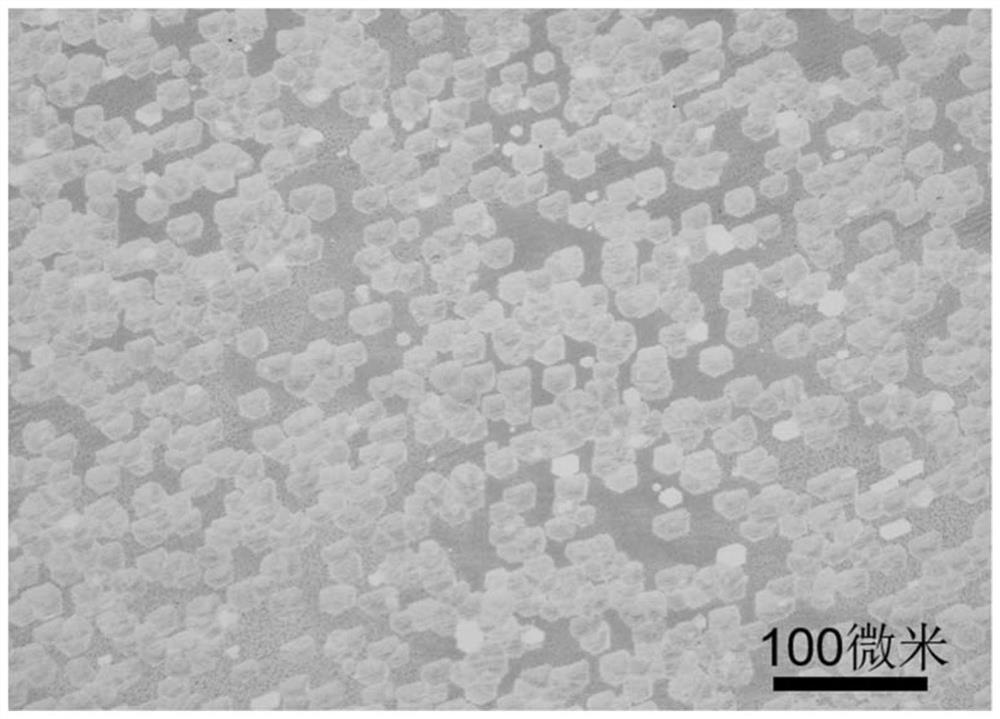

[0058] During this process, graphene islands will form oriented, multi-layer graphene single crystals on the surface of copper (111), such as figure 1 shown. With the prog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com